仓储认知——走进物流“仓”

Warehousing Understanding– A Journey into the Logistics "Warehouse"

一、仓储业务认知

Ⅰ. Understanding of Warehousing Operations

仓,warehouse ,中文也称为仓库,是货物被送到收货人之前临时存放的地方。若将现代物流体系比作一座精密运转的城市,那么仓库便是其中承载万千货物的“旅店”,货位就是货物在旅行中临时的家。在这里,货物并非静默堆积的物件,而是拥有独特“旅程”的“旅者”——它们或短暂停留、或长期驻守,等待与供应链的下一个环节相遇。

A warehouse, known as "仓" (cāng) in Chinese, is a temporary storage place for goods before they are delivered to the recipient. If we compare the modern logistics system to a precisely functioning city, then the warehouse is the "hotel" that accommodates countless goods, with each storage location serving as a temporary home for the goods during their journey. Here, goods are not merely silent, stacked objects but unique "travelers" with their own distinct journeys—they may stay briefly or reside for a longer period, awaiting their next encounter in the supply chain.

仓库的本质是为货物构建科学化的“暂居生态”,如同旅店为客人提供安全、舒适的休憩空间。在这所旅店中,“安全”是最高准则,消防系统如全天候值守的安保团队,区块链技术为“旅客身份”(货物信息)加上防伪锁,而周期盘点则像定期的“客房巡检”,确保每一件货物状态可溯、风险可控。仓库的入库区,相当于旅店登记前台,仓库的货架相当于旅店的房间,仓库的出库区,相当于旅店的旅客离店结算。仓库的运行管理方式,如同我们入住旅店一样。从“入住登记”(入库质检)到“客房分配”(储位规划),从“环境调控”(温湿度管理)到“行程定制”(出库调度),货物办理离店手续(出库验货)等。每一环节都暗藏管理的智慧。货架如“客房楼层”,按品类、周转率分层布局;库存系统似“前台管家”,借物联网技术记录每一件货物的“入住档案”;而AGV机器人则化身“服务生”,在算法的指引下精准完成“客房服务”(拣货配送)。

The essence of a warehouse is to create a scientific "temporary ecosystem" for goods, much like a hotel provides a safe and comfortable resting space for its guests. In this hotel, "safety" is the highest principle. The fire protection system acts as a 24/7 security team, block-chain technology adds an anti-counterfeiting lock to the "traveler's identity" (goods information), and periodic inventory checks are like regular "room inspections," ensuring that the status of every item is traceable and risks are controllable. The receiving area of the warehouse is akin to the hotel's front desk for check-in, the shelves are like the hotel rooms, and the shipping area is equivalent to the checkout counter. The operational management of a warehouse mirrors the experience of staying in a hotel. From "check-in registration" (inbound quality inspection) to "room assignment" (storage location planning), from "environmental control" (temperature and humidity management) to "itinerary customization" (outbound scheduling), and finally to "checkout procedures" (outbound inspection), each step is imbued with managerial wisdom. The shelves are like "hotel floors," organized by category and turnover rate; the inventory system acts as the "front desk manager," recording the "stay details" of each item through IoT technology; and AGV robots serve as "attendants," precisely performing "room service" (picking and delivery) under the guidance of algorithms.

二、仓储业务岗位认知

II. Understanding of Warehousing Operation Positions

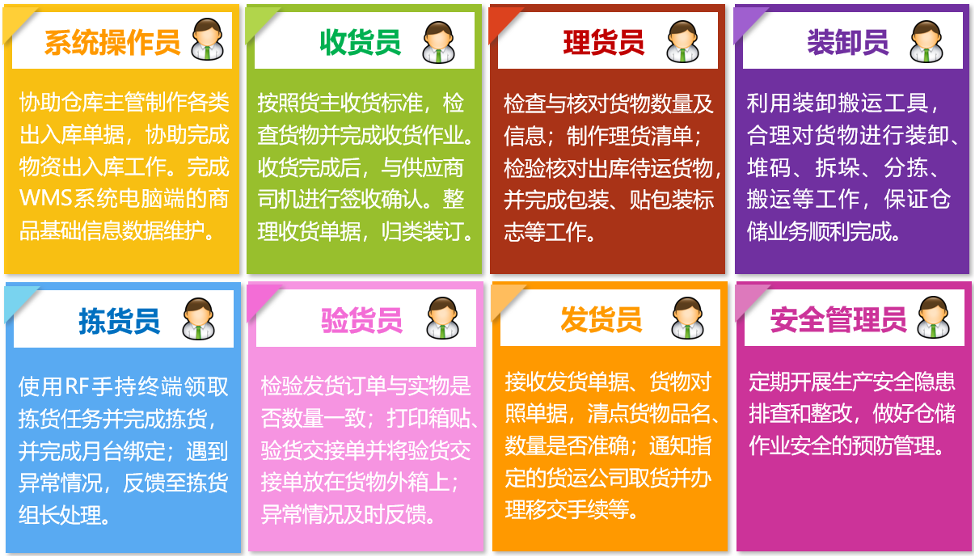

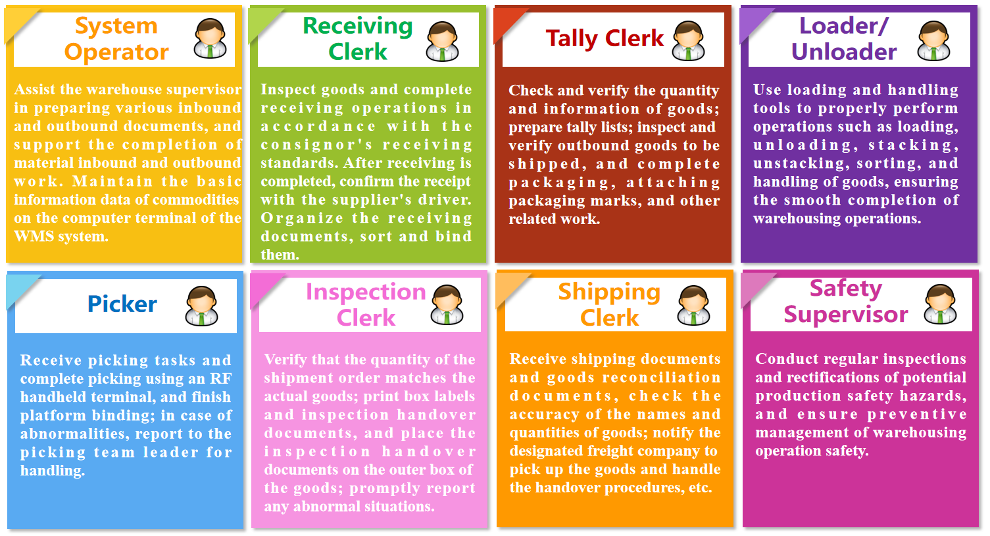

随着现代物流的发展和客户需求的差异化,仓储企业的操作岗位也呈现出多样化的趋势。仓储物流企业会根据企业业务流程需要,并结合自身业务特点,对企业操作部门的岗位设置进行适当调整和改造。一般来说,仓储部门主要操作岗位及其职责如下图所示。

With the development of modern logistics and the diversification of customer needs, operational positions in warehousing enterprises have shown a trend of diversification. Warehousing and logistics enterprises will appropriately adjust and reform the post settings of their operational departments according to the needs of business processes and in combination with their own business characteristics. Generally speaking, the main operational positions and their responsibilities in the warehousing department are shown in the figure below.

三、仓储功能区划分与功能说明

III. Division and Functional Description of Warehousing Functional Areas

现代化仓库早已打破传统库房单一存储属性,而是依托智能设备、数据管理系统与自动化技术支撑,其功能更趋多元高效。按照核心用途为划分依据,一般可将仓库划分为生产作业区、辅助生产区及行政商务区,各区域各司其职、协同联动,共同保障仓储物流全流程顺畅运转。

Modern warehouses have long transcended the single storage function of traditional warehouses. Supported by intelligent equipment, data management systems and automation technologies, their functions have become more diversified and efficient. Divided by core purposes, warehouses can generally be categorized into production operation areas, auxiliary production areas and administrative & business areas. Each area performs its own duties and collaborates interactively to ensure the smooth operation of the entire warehousing and logistics process.

1.生产作业区——核心价值创造区

生产作业区是智慧仓的核心枢纽,直接承载货物储运全链条关键作业,是仓储物流价值实现的核心载体。核心职能覆盖商品入库验收、智能存储、精准分拣、定制化包装、流通加工(如贴标、组装)及出库复核等全流程核心任务。

1.Production Operation Area – Core Value-Creation Zone

As the core hub of intelligent warehouses, the production operation area directly undertakes key operations throughout the entire cargo storage and transportation chain, serving as the primary carrier for realizing warehousing and logistics value. Its core functions cover end-to-end key tasks, including commodity warehousing acceptance, intelligent storage, precise sorting, customized packaging, distribution processing (e.g., labeling, assembly), and outbound review.

关键子区域包含:

(1)收货区(如货物接收、质检、信息录入);

(2)储货区(可依托立体货架、AGV机器人实现高密度智能存储);

(3)拣货区(按订单需求精准拣选货物);

(4)验货区(出库前质量与数量复核);

(5)发货区(货物集货、装载与发运调度),形成“收-存-拣-验-发”完整作业闭环。

Key sub-areas include:

a. Receiving area (for tasks such as goods receipt, quality inspection, and information entry);

b. Storage area (enabling high-density intelligent storage via racking systems and AGV robots);

c. Picking area (for accurate goods selection based on order requirements);

d. Inspection area (for quality and quantity verification before outbound);

e. Shipping area (for goods consolidation, loading, and dispatch scheduling).

Together, they form a complete operational closed loop of "receive-store-pick-inspect-ship".

2.辅助生产区——核心作业支撑区

辅助生产区围绕生产作业区需求提供全方位保障,是确保核心流程不中断、高效率运转的关键配套。核心职能聚焦设备运维、能源供应、车辆保障等支持性业务,为生产作业区提供稳定、安全的运营基础。

2.Auxiliary Production Area – Support Zone for Core Operations

The auxiliary production area provides comprehensive support tailored to the needs of the production operation area, serving as a critical supporting component to ensure the uninterrupted and efficient operation of core processes. Its core functions focus on supportive services such as equipment maintenance, energy supply, and vehicle support, laying a stable and safe operational foundation for the production operation area.

关键设施有:

(1)车库(采用智能调度系统,负责作业车辆、配送车辆的停放、充电与日常维护);

(2)变电室(配备智能监控模块,承担电力转换、稳压与持续供应,保障自动化设备、照明系统运行);

(3)油库(规范存储各类燃油,满足燃油动力设备的能源补给需求);

(4)维修车间(对仓储机器人、货架、输送线等设备进行定期保养与故障维修,延长设备使用寿命)等。

Key facilities include:

a. Garage (equipped with an intelligent scheduling system, responsible for parking, charging, and daily maintenance of operational vehicles and delivery vehicles);

b. Transformer room (fitted with intelligent monitoring modules, undertaking power conversion, voltage stabilization, and continuous supply to ensure the operation of automated equipment and lighting systems);

c. Oil depot (storing various types of fuel in a standardized manner to meet the energy supply needs of fuel-powered equipment);

d. Maintenance workshop (conducting regular maintenance and fault repair for warehousing robots, racks, conveyor lines, and other equipment to extend their service life); etc.

3.行政商务区——运营管理中枢区

行政商务区是智慧仓的决策指挥与信息交互核心,主导整体运营效率与对外协同质量。核心职能是负责智慧仓运营管理、战略规划、商务对接与信息统筹,是连接内部作业与外部客户、供应链上下游的关键纽带。

3.Administrative and Business Area – Operational Management Hub

The administrative and business area serves as the core of decision-making, command, and information exchange in intelligent warehouses, governing overall operational efficiency and the quality of external collaboration. Its core functions include managing intelligent warehouse operations, formulating strategic plans, conducting business liaison, and coordinating information, acting as a key link between internal operations, external clients, and upstream and downstream supply chain entities.

关键活动包括:

(1)制定仓储运营计划与优化方案;

(2)通过 WMS、TMS 等系统进行数据实时监控、订单调度与库存管理;

(3)开展客户洽谈、合同签订、对账结算等商务工作;

(4)统筹内部人员招聘、培训、绩效考核与日常管理;

(5)处理突发运营问题与跨部门协同沟通。

Key activities include:

a. Formulating warehousing operation plans and optimization schemes;

b. Conducting real-time data monitoring, order scheduling, and inventory management via systems such as WMS and TMS;

c. Carrying out business tasks including client negotiations, contract signing, and account reconciliation & settlement;

d. Coordinating internal personnel recruitment, training, performance appraisal, and daily management;

e. Handling sudden operational issues and cross-departmental collaborative communication.

四、走进海外仓

IV. An Introduction to Overseas Warehouses

近年来,中国物流企业海外仓建设加速,区域布局逐步优化,海外仓数量和总面积持续攀升。接下来,让我们以百世“云仓”、顺丰海外仓、京东物流海外仓为例,基于百世“云仓”的工作任务和流程,共同开启这场关于“空间、流程与作业”的探索之旅。

In recent years, Chinese logistics enterprises have accelerated the construction of overseas warehouses, with their regional layout gradually optimized and both the quantity and total area of overseas warehouses continuing to rise. Next, let's take Best's "Cloud Warehouse", SF Express Overseas Warehouses, and JD Logistics Overseas Warehouses as examples. Based on the work tasks and processes of Best's "Cloud Warehouse", we will jointly embark on this exploration journey focusing on "space, processes, and operations".

百世物流科技(中国)有限公司是中国高度发达的物流科技企业。百世408个云仓分布于国内及美国、泰国、越南、马来西亚等7个国家,总面积超过300万平方米,累计服务全球客户3000余家,拥有自主开发的智能供应链仓储管理系统,应用了各类先进的物流智能技术和相关配套设备,包括物流智能技术有物联网、大数据分析、云计算、自动化仓储、无人配送、智能路径规划和区块链等,物流智能设备有AMR自主移动机器人、AGV自动引导车、分拣机器人和无人叉车等。通过物流智能技术应用,提高仓储运行效率,为客户提供全渠道全链路数字化服务。

Best Logistics Technology (China) Co., Ltd. is a highly advanced logistics technology enterprise in China. Best operates 408 cloud warehouses distributed across China and seven other countries, including the United States, Thailand, Vietnam, and Malaysia, with a total area exceeding 3 million square meters. The company has served over 3,000 global clients and has independently developed an intelligent supply chain warehouse management system. It utilizes various advanced logistics technologies and related equipment, including IoT, big data analytics, cloud computing, automated warehousing, unmanned delivery, intelligent route planning, and block-chain. The intelligent logistics equipment includes AMR (Autonomous Mobile Robots), AGV (Automated Guided Vehicles), sorting robots, and unmanned forklifts. Through the application of these intelligent logistics technologies, Best enhances warehouse operational efficiency and provides customers with full-channel, end-to-end digital services.

“仓” “Warehouse”

顺丰于1993年成立于广东顺德,总部位于中国深圳。经过多年发展,顺丰已成为亚洲最大、全球第四大综合物流服务提供商。顺丰海外仓旨在为跨境电商和国际贸易企业提供端到端的供应链解决方案,已覆盖美国、欧盟27国、英国、泰国等全球多个国家和地区。

SF Express was founded in Shunde, Guangdong in 1993, with its headquarters located in Shenzhen, China. Through years of development, it has grown into the largest comprehensive logistics service provider in Asia and the fourth largest globally. SF Express Overseas Warehouses aim to provide end-to-end supply chain solutions for cross-border e-commerce and international trade enterprises, covering multiple countries and regions worldwide including the United States, the 27 EU countries, the United Kingdom, and Thailand.

顺丰美国洛杉矶S5仓是其深耕北美西海岸市场的关键战略节点,位于加州Riverside,依托得天独厚的区位优势,与洛杉矶港、长滩港及国际机场高效联动,形成“港—仓—配”一体化物流网络,搭载顺丰自有的智能仓储管理系统(WMS),实现订单信息实时同步,通过库存分配、波次生成、智能拣货、复核贴单到发运调度的全流程标准化作业。西班牙马德里仓位于马德里南部核心物流区,距离马德里机场仅27公里,仓库总占地面积达3万平方米,配备60个现代化装卸平台,采用高标准立体仓储系统,可提供保税暂存服务。德国门兴仓地处德国北威州,2小时车程辐射圈覆盖鹿特丹港、安特卫普港及科隆/列日机场等核心节点,仓库总面积2.3万平方米,配备74个智能化装卸平台,还有7千平方米弹性扩容区,峰值日处理能力达15柜入库、超7千个订单出库。

SF Express's S5 Warehouse in Los Angeles, USA, is a key strategic node for its deep cultivation in the North American West Coast market. Located in Riverside, California, it leverages its unique geographical advantages to efficiently connect with the Port of Los Angeles, Port of Long Beach, and international airports, forming an integrated "port-warehouse-delivery" logistics network. Equipped with SF Express's proprietary intelligent Warehouse Management System (WMS), it realizes real-time synchronization of order information and conducts standardized full-process operations from inventory allocation, wave generation, intelligent picking, review and labeling to dispatch scheduling. The Madrid Warehouse in Spain is situated in the core logistics zone south of Madrid, merely 27 kilometers from Madrid Airport. With a total area of 30,000 square meters, it is equipped with 60 modern loading/unloading platforms and adopts a high-standard stereoscopic warehousing system, capable of providing bonded temporary storage services.The Monchengladbach Warehouse in Germany is located in North Rhine-Westphalia. Within a 2-hour driving radius, it covers core nodes such as the Port of Rotterdam, Port of Antwerp, and Cologne/Liège Airport. With a total area of 23,000 square meters, it features 74 intelligent loading/unloading platforms and a 7,000-square-meter flexible expansion area, boasting a peak daily processing capacity of 15 containers for inbound storage and over 7,000 orders for outbound delivery.

京东集团2007年开始自建物流,2017年4月正式成立京东物流集团。京东物流是中国领先的技术驱动的供应链解决方案及物流服务商,以“技术驱动,引领全球高效流通和可持续发展”为使命,致力于成为全球最值得信赖的供应链基础设施服务商。京东物流海外仓已覆盖全球23个国家和地区,通过领先的自动化设备应用、库存管理系统升级、运营流程优化等,为全球客户提供优质高效的一体化供应链物流服务,以海外仓为核心更推动在美国、欧洲地区、大洋洲地区、东南亚等国家、地区快递物流大提速。2025年6月,京东物流已在沙特启动配送业务,推出自营快递品牌“JoyExpress”,着力构建涵盖跨境运输、清关、本地运输等环节的时效快递服务能力。同年8月,在阿联酋迪拜的杰巴阿里保税区,京东物流迪拜5号仓正式开仓运营,该仓库为京东物流与京东产发联合开发,是京东物流在中东运营的第9个高标准海外仓,在上万平米的仓库中,存储有近100万件大中小多样件型的货物,借由这一仓库,这些优质商品将销往阿联酋、沙特等中东地区国家。

JD.com began building its own logistics system in 2007 and officially established JD Logistics Group in April 2017. As a leading technology-driven supply chain solutions and logistics service provider in China, JD Logistics takes "Driven by technology, leading global efficient circulation and sustainable development" as its mission and is committed to becoming the world's most trusted supply chain infrastructure service provider. JD Logistics' overseas warehouses have covered 23 countries and regions worldwide. Through the application of advanced automated equipment, upgrading of inventory management systems, optimization of operational processes, and other initiatives, it provides global customers with high-quality and efficient integrated supply chain logistics services. With overseas warehouses as the core, it has further accelerated express logistics in regions such as the United States, Europe, Oceania, and Southeast Asia. In June 2025, JD Logistics launched its delivery business in Saudi Arabia and introduced its self-operated express brand "JoyExpress", focusing on building time-definite express service capabilities covering cross-border transportation, customs clearance, local transportation, and other links. In August of the same year, JD Logistics Dubai Warehouse No.5 was officially opened and put into operation in Jebel Ali Free Zone, Dubai, UAE. Co-developed by JD Logistics and JD Property, this warehouse is the 9th high-standard overseas warehouse operated by JD Logistics in the Middle East. Covering an area of over 10,000 square meters, it stores nearly 1 million items of various sizes, which will be sold to countries in the Middle East such as the UAE and Saudi Arabia through this warehouse.