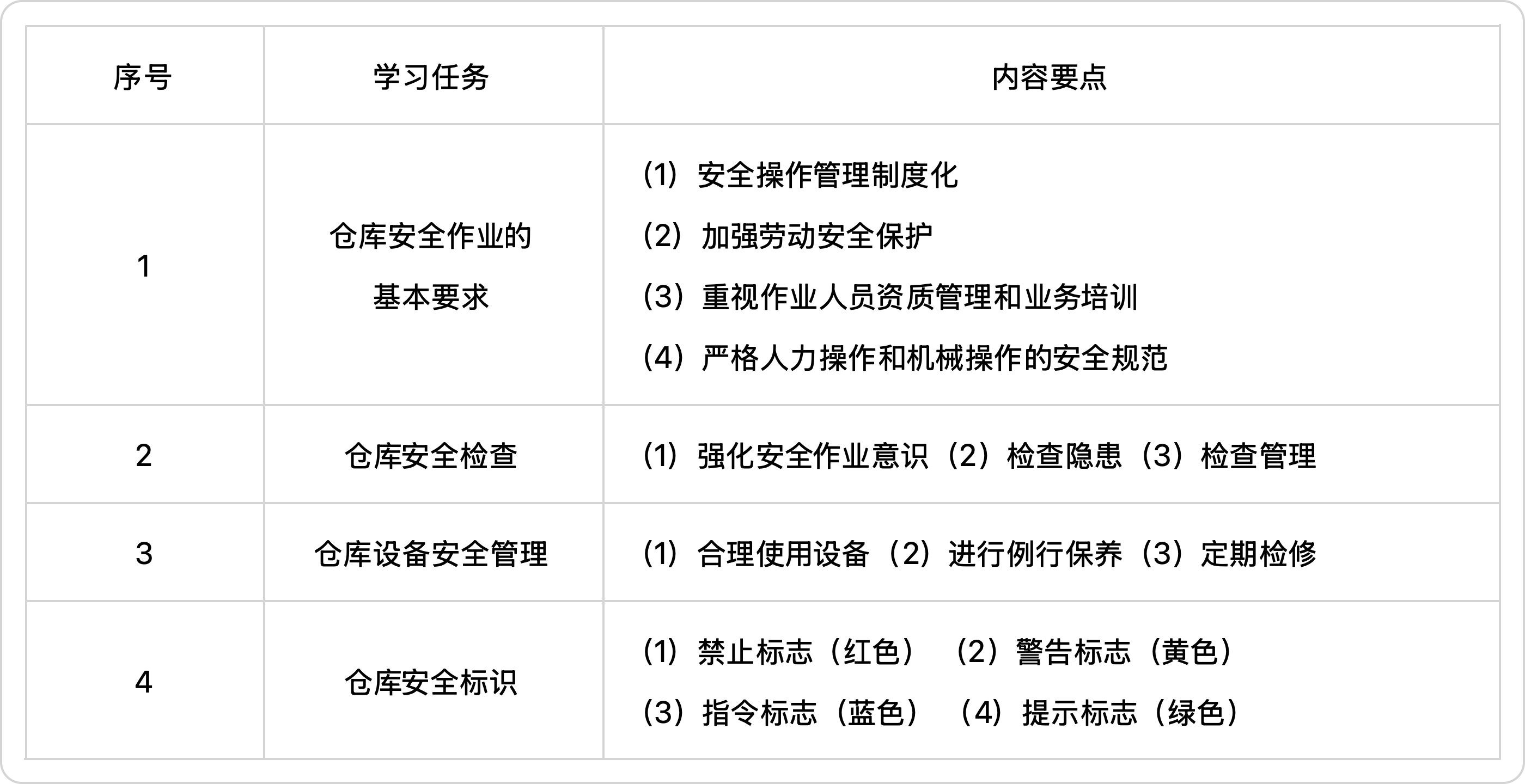

任务1 仓储作业安全管理

Task One Safety Management of Warehousing Operations

任务导入 Lead-in

仓储王经理:王霞,下周一统一安排新员工入职,按照企业要求,先进行岗前安全培训教育工作,这项任务你安排的怎么样了

培训组负责人王霞:王经理,新员工的安全培训工作都已准备就绪,培训课程包括仓储安全管理教育课程和实践课程,培训内容涵盖公司安全管理规章制度作业安全基础知识岗位安全职责消防急救常识各类应急预案等,并考虑通过安全教育安全宣讲现场安全演练等多种形式进一步提升培训效率和效果。

仓储王经理:很好,对于新入职员工的安全培训教育公司高度重视,培训内容要丰富多样形式要灵活,通过培训筑牢新员工的安全意识切实提高新员工的安全素养。

培训组负责人王霞:好的经理,具体工作细节我再去安排下。

Manager Wang of the Warehouse: Wang Xia, new employees will join us on next Monday. In accordance with the requirements of the company, pre-job safety training and education will be held. How are things going?

Wang Xia, the person in charge of the training group: Manager Wang, the safety training of new employees is ready, which includes warehouse safety management education courses and practical courses. The training content covers the company's safety management rules and regulations, basic knowledge of operation safety, position safety responsibilities, fire first aid knowledge, various emergency plans, etc., and includes further improving the training efficiency and effect through safety education, safety preaching, on-site safety drills and other forms.

Manager Wang of the Warehouse: Very good. The company attaches great importance to the safety training and education of new employees. The training content should be rich and diverse, the form should be flexible, and the safety awareness of new employees should be built through training, and the safety literacy of new employees should be effectively improved.

Wang Xia, the person in charge of the training group: Okay manager. I'll arrange the details.

仓储安全作业管理直接关系到货物的安全、作业人员人身安全、生产安全、作业设备和仓库设施的安全,也关系到仓库的劳动生产率能否提高。

仓储主管应熟悉仓库安全作业的基本要求,根据所管辖的业务范围制定仓库安全作业的管理制度,并定期开展生产安全隐患排查和整改。仓库人员还要特别注意作业安全管理,特别是重视作业安全的预防管理,避免发生作业安全事故。

Warehouse safety operation management is directly related to the safety of goods, the personal safety of operators, production safety, the safety of operating equipment and warehouse facilities, and whether the labor productivity of the warehouse can be improved.

The warehouse supervisor should be familiar with the basic requirements of warehouse safety operation, formulate a management system for it according to the business scope under his jurisdiction, and regularly carry out investigation and rectification of production safety hazards. Warehouse personnel should also pay special attention to operation safety management, especially pay attention to the prevention and management of operation safety, so as to avoid operation safety accidents.

仓库安全作业的基本要求 Basic requirements for Safe Warehouse Operations

安全操作管理制度化

仓储安全作业管理应成为仓库日常管理的重要项目,仓库应制定科学合理的仓储作业安全制度、操作规程和安全责任制度,并通过严格的监督,确保管理制度得以有效和充分的运行。

Institutionalization of safety operation management

Warehouse safety operation management should be an important item of daily management of the warehouse. The warehouse should develop a scientific and reasonable warehouse operation safety system, operating procedures and safety responsibility system to ensure that the management system can be effective and full operation through strict supervision.

加强劳动安全保护

劳动安全保护包括直接和间接施行于员工人身的保护措施。提供合适和足够的劳动防护用品,如高强度工作鞋、安全帽、手套、工作服等,并督促作业人员使用和穿戴。采用具有较高安全系数的作业设备、作业机械,作业工具应适合作业要求,作业场地必须具有合适的通风、照明、防滑、保暖等适合作业的条件。不进行冒险的仓储作业和不安全环境的作业,在大风、雨雪影响作业时暂缓作业。避免人员带伤病作业。

Strengthen labor safety protection

Occupational safety protection includes measures that are directly and indirectly applied to the personal protection of employees. Provide appropriate and sufficient labor protection equipment, such as high-strength work shoes, helmets, gloves, work clothes, etc., and urge workers to use and wear them. Operating equipment and machinery with a high safety factor should be used, the working tools should be suitable for the operation requirements, and the working site must be in suitable ventilation, lighting, anti-skidding, warmth and other suitable conditions for the operation. Risky warehousing operations or operations in unsafe environments are forbidden, and suspend operations when under the influence of strong winds, rain, and snow. Avoid personnel working with injuries and illnesses.

重视作业人员资质管理和业务培训

新参加仓库工作和转岗的员工,应进行仓储安全教育,对所从事的作业进行安全作业教育和操作培训,确保熟练掌握岗位的安全作业技能和规范。从事特种作业的员工必须经过专门培训并取得特种作业资格,才能上岗作业,且仅能从事其资格证书限定的作业项目操作,不能混岗作业。安全作业宣传和教育是仓库的长期性工作,作业安全检查是仓库安全作业管理的日常工作。通过不断的宣传、严格的检查,对违章和无视安全的行为给予严厉的惩罚,强化作业人员的安全责任心。

Pay attention to the qualification management and business training of operators

Employees who are newly involved in warehouse work and transferred positions should receive warehouse safety education, safety operation education and operation training for the operations they are engaged in, and ensure that they are proficient in the safety operation skills and specifications of the post. Employees engaged in special operations must undergo special training and obtain special operation qualifications before they are allowed to operate, and can only engage in the operation of the operation items limited by their qualification certificates, and cannot work in mixed positions. Safety operation publicity and education is a long-term project for the warehouse, and the operation safety inspection is the daily work of the warehouse safety operation management. Through continuous publicity and strict inspection, severe punishments are given to violations and disregard for safety, and the safety responsibility of operators is strengthened.

严格人力操作和机械操作的安全规范

人力作业的安全操作要求

由于人工作业方式受到作业人员的身体素质、精神状况和感知能力、应急能力等多种因素的影响,因此必须做好作业人员的安全作业管理工作,具体要求有:人力操作仅限制在轻负荷的作业;尽可能采用人力机械作业;只在适合作业的安全环境进行作业;作业人员按要求穿戴相应的安全防护用具,使用合适的作业工具进行作业;合理安排工间休息;必须有专人在现场指挥和安全指导,严格按照安全规范进行作业指挥。

Strict safety standards for manual operation and mechanical operation

Requirements for safe operation of manual operations

As the manual operation mode is affected by various factors such as the physical fitness, mental condition and perception ability of the operator, and the emergency response ability, it is necessary to make sure of the safe operation management of the operator, and the specific requirements are: the manual operation is only limited to the operation of light load; Adopt manpower and machinery as much as possible; Work only in a safe environment suitable for work; Operators wear corresponding safety protection equipment as required and use appropriate operating tools to carry out operations; Arrange work breaks reasonably; There must be a special person on site to command and provide safety guidance, and conduct operation command in strict accordance with safety specifications.

机械作业的安全要求

机械安全作业管理的内容主要是注意机械本身状况及可能对商品造成的损害,树立设备良好、专人操作、规范作业的机械作业意识。具体要求有:使用合适的机械、设备进行作业;所使用的设备具有良好的工况;设备作业要有专人进行指挥;汽车装卸时,注意保持安全间距;载货移动设备上不得载人运行;移动吊车必须在停放稳定后方可作业。

Safety requirements for mechanical operations

Machinery safety operation management mainly refers to the condition of the machinery itself and the damage that may be caused to the goods, and establish the awareness of mechanical operation with good equipment, special operation and standardized operation. The specific requirements are: the use of appropriate machinery and equipment for operation; The equipment used is in good working condition; There should be a special person to command the equipment operation; When loading and unloading cars, pay attention to maintaining a safe distance; Goods mobile equipment shall not be manned; The mobile crane must be parked and stabilized before it operated.

仓库安全检查 Warehouse Security Checks

仓库要认真做好安全检查工作,将定期全面安全检查、经常性安全检查、专业性安全检查、季节性安全检查和临时性安全检查结合起来,从以下方面入手:

The warehouse should conscientiously make sure of safety inspection, and combine regular comprehensive safety inspections, regular safety inspections, professional safety inspections, seasonal safety inspections and temporary safety inspections. It refers to the following aspects:

强化安全作业意识

首先要检查仓库人员是否已建立安全作业的观念,是否牢固树立“安全第一”的思想;其次要检查领导是否切实关心职工、设备、库存商品的安全,是否严格执行安全教育制度、作业规范标准等。

Strengthen the awareness of safe operation

First of all, it is necessary to check whether the warehouse personnel have established the concept of safe operation and whether they have firmly established the idea of "safety first"; Secondly, it is necessary to check whether the leaders are really concerned about the safety of employees, equipment, and inventory goods, and whether they strictly implement the safety education system and operation norms.

检查隐患

仓库主管要深入仓库生产作业现场,重点检查生产工人的劳动条件是否符合作业规定,操作程序是否符合相应规程,各种机械设备是否符合安全标准,商品堆放是否稳固,有无倾斜或倒塌隐患,是否符合作业要求;储油库、化工储罐、剧毒品、放射性商品是否严格管理等。

Check for hidden dangers

The warehouse supervisor should check the warehouse production site carefully, focusing on checking whether the working conditions of the production workers meet the operation regulations, whether the operating procedures comply with the corresponding regulations, whether all kinds of machinery and equipment meet the safety standards, whether the goods are stacked steadily, whether there is any potential danger of tilting or collapse, and whether it meets the operation requirements; Whether oil storage depots, chemical storage tanks, highly toxic drugs, and radioactive commodities are strictly managed.

检查管理

管理方面主要检查:仓库作业各岗位的安全操作制度和规程是否都已建立、健全,执行情况如何;劳动防护用品是否按规定发放,员工是否按照规定使用;各级安全生产责任制度贯彻落实的情况如何;对仓库事故伤亡报告的统计和处理是否按法规认真执行等。

Inspection management

In terms of management, the main inspections are: whether the safety operation systems and procedures of each position in the warehouse operation have been established and improved, and how the implementation is; whether the labor protection equipment is distributed in accordance with the regulations, and whether the employees use it in accordance with the regulations; the implementation of the safety production responsibility system at all levels; Whether the statistics and processing of warehouse accident casualty reports are conscientiously implemented in accordance with laws and regulations.

仓库设备安全管理 Warehouse Equipment Safety Management

合理使用设备

加强对操作人员的技术训练,严格考核制度

首先要对操作工人进行技术训练,是他们会使用、会保养、会排除故障,并熟悉设备的性能。在设备作业过程中,必须严格遵守安全操作规程。

合理安全工作负荷

在安排设备工作量时,应根据设备本身的技术操作要求和任务量,经过科学的计算,合理确定工作负荷。

建立健全设备使用与维护保养规程和制度

设备的使用和维护保养是密切联系的,合地使用设备实质上就是对设备的维护。

Proper use of equipment

Strengthen the technical training of operators and strict assessment system

First of all, the operator should be trained in technical training, that is, they will use, maintain, troubleshoot, and be familiar with the performance of the equipment. In the process of equipment operation, the safety operation procedures must be strictly observed.

Reasonable and safe working load

When arranging the workload of the equipment, the workload should be reasonably determined according to the technical operation requirements and task volume of the equipment itself, after scientific calculation.

Establish and improve equipment use and maintenance procedures and systems

The use and maintenance of equipment are closely linked, and the use of equipment in combination is essentially the maintenance of equipment.

进行例行保养

设备的维护保养一般应达到四项要求:

齐备

工具、工件、附件要齐备,放置整齐,安全防护装置齐全。

润滑

按照规定加油、换油,润滑剂性能符合要求。

清洁

工作场所、设备内外清洁,各滑动面、齿轮、齿条等无尘、无油垢、无碰伤和划痕。设备各部分无漏油、漏水、漏气等现象。

安全

严格按照设备操作规程使用,不允许超载运行。各种测量仪器、保护装置、机电设备和动力设备应定期进行检查,符合要求才能继续使用。设备的维护保养是设备自身运行的客观要求,设备在使用过程中必然会产生变化,如零件磨损、松动等,这些隐患如不及时处理,就会造成设备过早损坏,甚至导致发生严重事故。实践证明,设备的使用寿命很大程度上取决于维护保养的好坏。

Carry out routine maintenance

The maintenance of the equipment should generally meet four requirements:

Complete

Tools, workpieces, and accessories should be complete, placed neatly, and the safety protection devices should be complete.

Lubrication

In accordance with the regulations, oil refueling, oil change, lubricant performance meets the requirements.

Cleaning

The workplace and equipment are clean inside and outside, and the sliding surfaces, gears, racks, etc. are free of dust, grease, bumps and scratches. There is no oil leakage, water leakage, air leakage and other phenomena in all parts of the equipment.

Security

It is used in strict accordance with the equipment operating procedures, and overload operation is not allowed. All kinds of measuring instruments, protective devices, electromechanical equipment and power equipment should be inspected regularly and meet the requirements before they can continue to be used. The maintenance of the equipment is the objective requirement of the operation of the equipment itself, and the equipment will inevitably change in the process of use, such as wear and tear of parts, loosening, etc., if these hidden dangers are not dealt with in time, it will cause premature damage to the equipment, and even lead to serious accidents. Practice has proved that the service life of equipment depends largely on the quality of maintenance.

定期检修

通过检查,可以全面的掌握机器设备技术状况的变化和磨损情况,及时查明和消除隐患;针对检查发现的问题,提出设备维护措施;有目的的做好修理前的各项准备工作。

Regular maintenance

Through inspection, we can fully grasp the changes and wear of the technical condition of machinery and equipment, and identify and eliminate hidden dangers in time; In view of the problems found in the inspection, equipment maintenance measures are proposed; Purposefully prepare for repairs.

仓库安全标识 Warehouse Security Markings

安全标志和安全色是在仓储作业现场中,最基本的元素,是仓库员工应掌握的最基础的安全知识。当危险发生时能够指示人们尽快逃离或者指示人们采取正确、有效、得力的措施对危害加以遏制。

Safety signs and safety colors are the most basic elements in the warehouse operation site, and they are the most basic safety knowledge that warehouse employees should master. When danger occurs, it can instruct people to flee as soon as possible, or instruct people to take correct, effective and effective measures to contain the harm.

禁止标志

禁止标志是禁止人们不安全行为的图形标志。禁止标志的几何图形是带斜杠的圆环,其中圆环与斜杠相连,用红色;图形符号用黑色,背景用白色。如禁止吸烟、禁止烟火、禁止带火种、禁止用水灭火、禁止放置易燃物等(图4.1.1)。

Prohibitory signs

Prohibitory signs are graphic signs that prohibit people from dangers. The geometry of the prohibitory sign is a ring with a slash, where the ring is connected to a slash in red; Black for graphic symbols and white for background. For example, no smoking, no fireworks, no fire, no water extinguishing, no flammable materials, and etc.(Figure 4.1.1).

警告标志

警告标志是提醒人们对周围环境引起注意,以避免可能发生危险的图形标志。警告标志的几何图形是黑色的正三角形、黑色符号和黄色背景。如:当心叉车、当心触电、当心机械伤人、当心挤压、当心中毒等(图4.1.2)。

Warning signs

Warning signs are graphic signs that alert people to their surroundings to avoid possible dangers. The geometry of the warning sign is a black triangle, black symbols, and a yellow background. For example, beware of forklifts, beware of electric shock, beware of mechanical injuries, beware of squeezing, beware of poisoning, etc. (Figure 4.1.2).

指令标志

指令标志是强制人们必须做出某种动作或采用防范措施的图形标志。指令标志的几何图形是圆形、蓝色背景、白色图形符号,如必须系安全带、必须戴安全帽、注意通风等(图4.1.3)。

Instruction signs

Command signs are graphic signs that force people to have to do a certain action or take precautions. The geometric shape of the command sign is a circle, a blue background, and white graphic symbols, such as wearing a seat belt, wearing a safety helmet, paying attention to ventilation, etc. (Figure 4.1.3).

提示标志

绿色标志是向人们提供某种信息(如标明安全设施或场所)。提示标志的几何图形是方形,绿色背景,白色图形符号及文字(图4.1.4)。

Reminder signs

A green sign is one that provides people with some kind of information (such as indicating a safety facility or place). The geometric shape of the cue sign is a square, green background, white graphic symbols and text. (Figure 4.1.4)

专业核心词汇 Vocabulary

定期全面安全检查 regular and comprehensive safety inspections

经常性安全检查 regular safety inspections

专业性安全检查 professional safety inspections

季节性安全检查 seasonal security inspections

临时性安全检查 temporary safety inspection

安全作业意识 awareness of safe operation

例行保养 routine maintenance

定期检修 regular maintenance

禁止标志 prohibitory signs

警告标志 warning signs

指令标志 instruction signs

提示标志 reminder signs

学习拓展 Further Reading

仓库事故的处理

仓库事故主要表现为:物品直接受损(爆炸、设备损坏)、人员伤亡、信息失控等。

仓库事故管理是安全管理的重要部分,仓库发生事故往往损失大、影响广,了解仓库事故管理也是非常必要的。

1.相关人员的处理

事故相关人员主要有事故中伤亡人员、责任人、有功人员。根据相关的抚慰政策对事故中伤亡人员给予妥善地安置和处理;依照相关法律、规章和纪律的有关规定,据其责任轻重,予以处罚或处理;按照有关规定对事故中表现突出的有功人员进行表彰和奖励。

2.事故损失的处理

仓库事故发生后,会造成不同程度的损失。应按照有关的规定和程序进行处理:可修复的,制定计划报请有关部门批准,予以修复;报废的,报请有关部门审批;涉及到责任人的应按相关规定进行赔偿;已入保险的,向保险公司进行索赔。

3.总结教训

事故发生后,应认真总结教训。据事故发生的原因、后果及各种影响因素,进行分析、总结,找出薄弱环节,提出相应改进措施,不断提高认识,以便更好地指导今后的工作。

4.建立预警机制

在总结教训的基础上,有针对性地采取防范措施,提出预防事故的目标和要求,制定有关的规章制度,加强人员的思想教育,提高安全防范使得各项措施落到实处,一旦发生事故,能够及时应对。

Handling of Warehouse Accidents

Warehouse accidents are mainly manifested in: direct damage to items (explosion, equipment damage), casualties, loss of information control, etc.

Warehouse accident management is an important part of safety management because it often leads to large losses and has wide impact, and it is also very necessary to know warehouse accident management.

1.Handling of relevant personnel

The personnel involved in the accident mainly include the casualties in the accident, the responsible persons, and the meritorious personnel. Properly resettle and deal with the casualties in the accident in accordance with the relevant comfort policies; In accordance with the relevant provisions of relevant laws, rules and disciplines, punishment or punishment shall be given according to the severity of their responsibility; In accordance with the relevant regulations, commendations and awards are to be given to those who have made outstanding contributions to the accident.

2.Handling of accident losses

After the warehouse accident occurs, it will cause different degrees of losses. It should be dealt with in accordance with the relevant regulations and procedures: if it can be repaired, a plan shall be formulated and submitted to the relevant departments for approval and repair; if it is scrapped, it shall be submitted to the relevant departments for approval; If the responsible person is involved, compensation shall be made in accordance with relevant regulations; If you are already insured, you should make a claim to the insurance company.

3.Summarize the lessons

After an accident occurs, lessons should be carefully summed up. According to the causes, consequences and various influencing factors of the accident, analyze and summarize, find out the weak links, put forward corresponding improvement measures, and continuously improve the understanding in order to better guide the future work.

4.Establish an early warning mechanism

On the basis of summing up the lessons, we should take preventive measures in a targeted manner, put forward the goals and requirements for accident prevention, formulate relevant rules and regulations, strengthen the ideological education of personnel, improve safety precautions, and implement various measures so that once an accident occurs, it can be dealt with in a timely manner.

知识巩固 Consolidation

看图填空

安全作业标识知多少

请看下方图片,依次写出各作业标识代表的含义。

答案:

1.禁止带火种 2.禁止烟火 3.禁止通行

4.紧急出口 5.击碎板面 6.当心触电

7.当心机械伤人 8.当心落物 9.必须戴防护手套

10.注意通风选择题

1.提醒人们对周围环境引起注意,以避免可能发生危险,应该考虑使用( )。

A.禁止标志

B.警告标志

C.指令标志

D.提示标志

答案:B2.在配电室开关等场所应当设置( )安全标志 。

A.当心叉车

B.当心挤压

C.当心机械伤人

D.当心触电

答案:D3.在易发生机械卷入轧压碾压剪切等伤害的机械作业车间,应当设置( )安全标志 。

A.必须戴安全帽

B.禁止入内

C.当心机械伤人

D.必须戴防护手套

答案:C判断题

1.新参加仓库工作和转岗的员工,应进行仓储安全教育,对所从事的作业进行安全作业教育和操作培训,确保熟练掌握岗位的安全作业技能和规范。( )

答案:√2.设备在使用过程中必然会产生变化,如零件磨损松动等,这些隐患如不及时处理,就会造成设备过早损坏,甚至导致发生严重事故。( )

答案:√技能训练

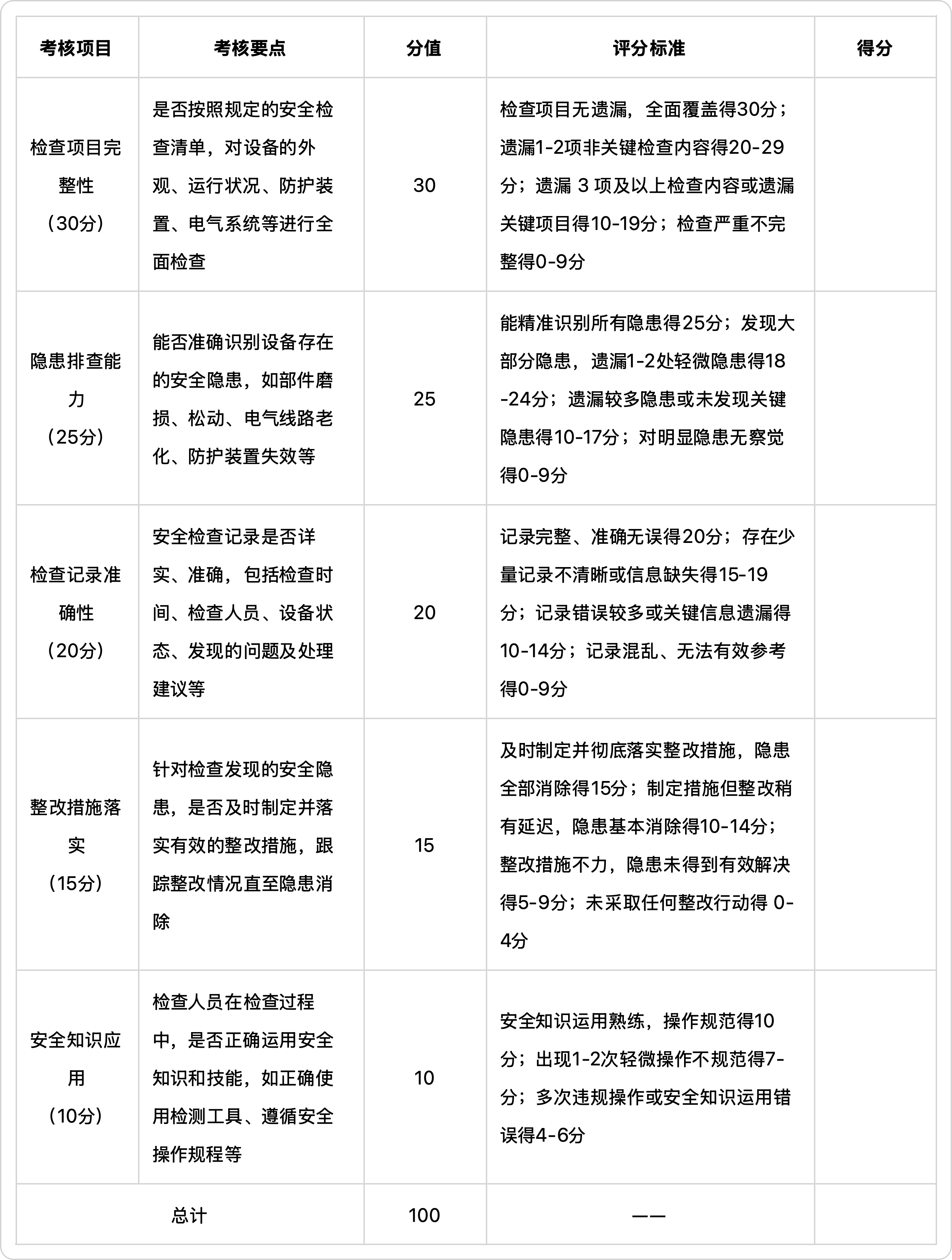

训练任务 检查仓储作业安全

【训练目标】

1.在仓储作业现场中,能够发现并指出各种不安全因素。

2.能够分析安全隐患产生的原因,并采取有力措施解决或消除不安全因素。

【训练内容】

下面两张图(图4.1.5)是某仓库工作现场的监控所拍摄到的场景,请根据图片所展示的内容,分析并指出该操作现场存在的作业安全隐患问题。

【训练步骤】

1.小组成员明确训练任务。

2.熟悉仓储安全作业的基本要求及仓储安全检查重点。

3.制定仓储安全检查表,并填写检查记录。

4.排查安全隐患梳理出现的不安全问题,并分析原因。

5.提出整改建议并形成文字报告。

6.小组分享仓储安全检查成果。

【考核评价】

微课

仓储作业安全管理

仓储生产安全管理

工作视频

仓储安全管理-1学习准备

仓储安全管理-2法律法规

仓储安全管理-3常见作业风险与注意事项

仓储安全管理-4安全基础技能

课件

任务小结

本节课学习任务要点梳理如表4.1.2所示: