任务3 拣货作业

Task Three Picking Operation

任务导入 Lead-in

系统组小王:宋组长,今天上午8:0010:00的订单,我已经汇总到一个波次,并生成拣货单了。

拣货组宋组长:好的小王,我马上安排开始拣货。

系统组小王:辛苦了,宋组长。

拣货组宋组长:这次的分组规则是什么

系统组小王:这次分组,是按照货主进行分组,同一货主的货物我们一起拣选。

拣货组宋组长:我明白了

Member Xiao Wang of System Team: Team Leader Song, I have summarized the orders from 8:00 to 10:00 this morning into one wave and generated a picking list.

Leader Song of Picking Team: Alright, Xiao Wang, I'll arrange to start picking right away.

Member Xiao Wang of System Team: Thank you for your hard work, Leader Song.

Leader Song of Picking Team: What are the grouping rules for this time?

Member Xiao Wang of System Team: This grouping is based on the shipper, and we pick goods from the same shipper together.

Leader Song of Picking Team: I got it.

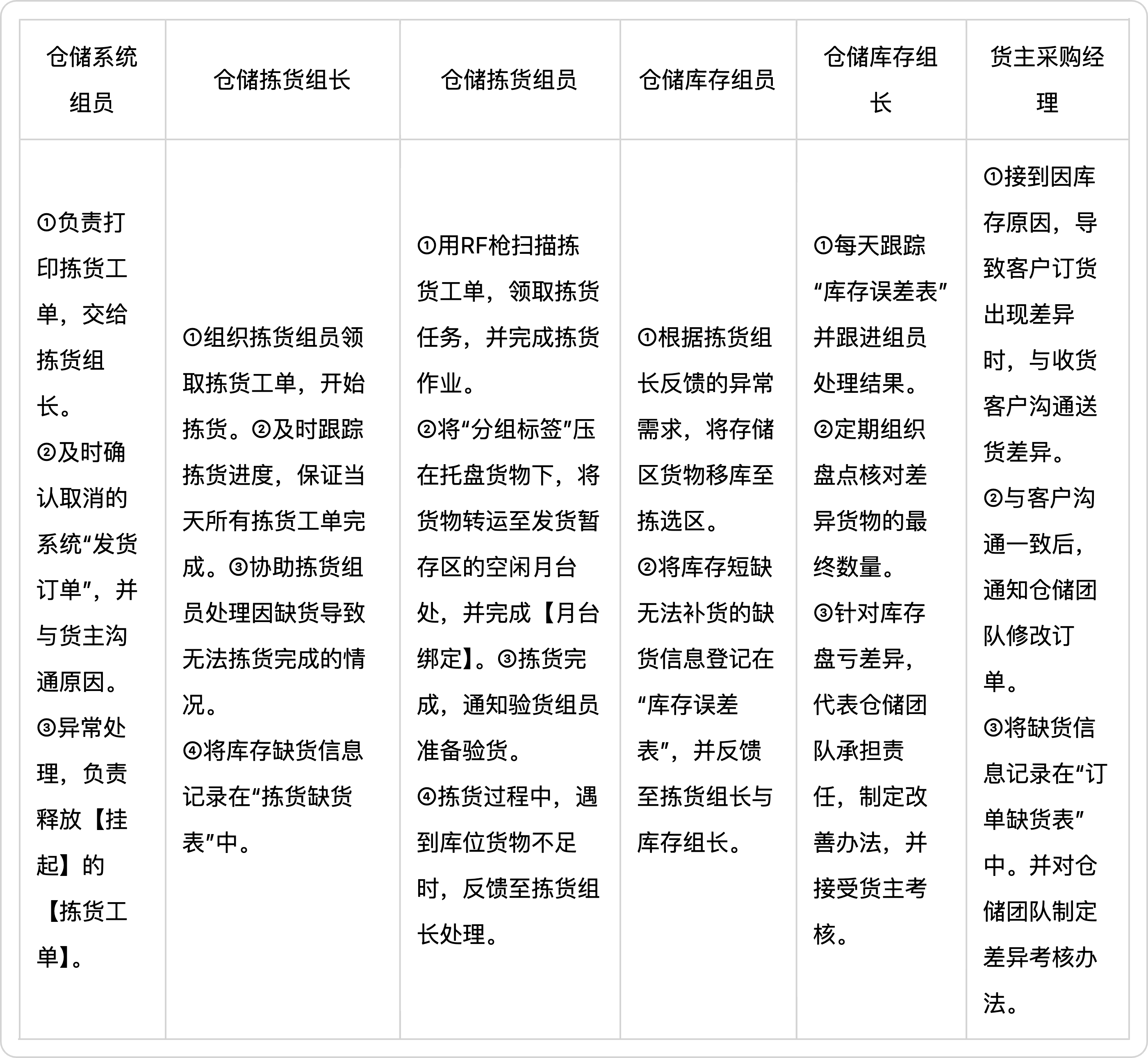

拣货岗位人员及其职责 Picking Personnel and Their Responsibilities

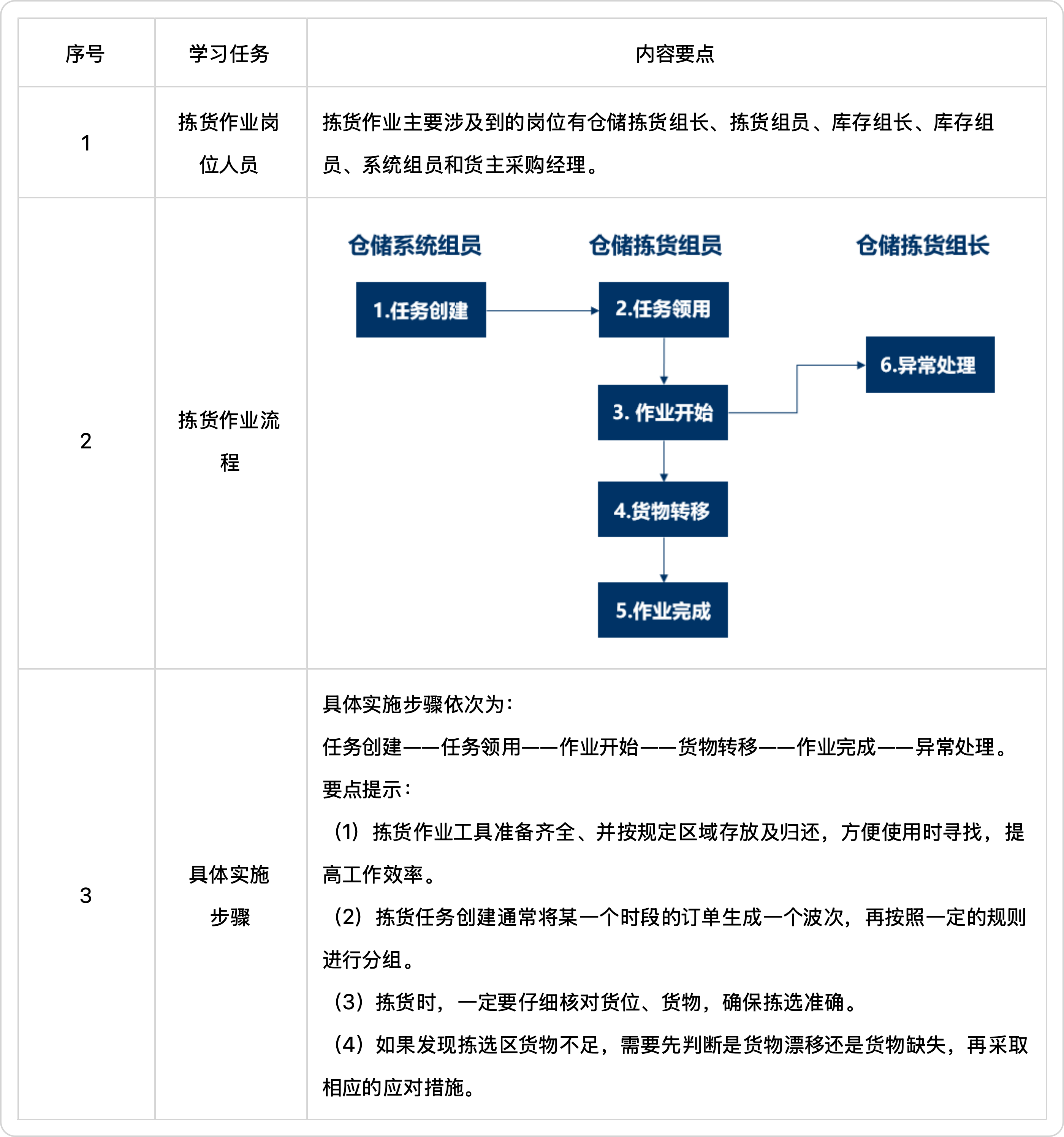

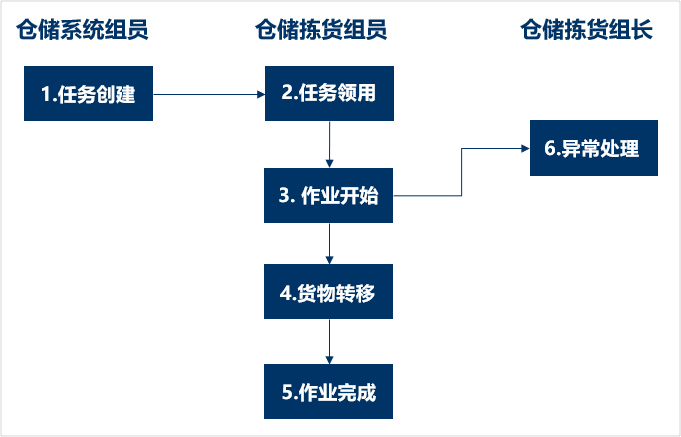

拣货作业流程 Picking Operation Process

具体实施步骤 Specific Implementation Steps

任务创建

创建波次订单

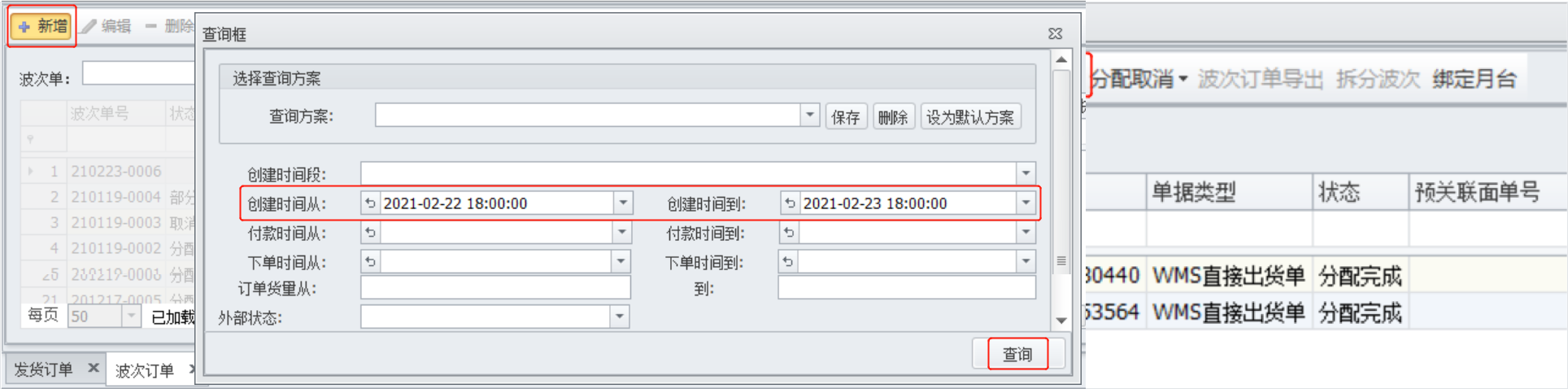

系统组员在【WMS】系统中,按照一定的订单时间段(例如,从昨天的截单时间点到今天的截单时间点)汇总客户订单,生成相应的波次订单,完成波次分配操作(图3.3.2)。

Task creation

Create wave order

System team members in the WMS system summarize customer orders according to a certain order time period (e.g. from yesterday's cut-off time to today's cut-off time), generate corresponding wave orders, and complete wave allocation operations. (Figure 3.3.2)

生成拣货单

系统组员将已经分配完成的波次订单,按照一定的规则进行分组(比如相同收货方的订单合并拣货,或者相同货主的订单合并拣货),并打印生成相应的分组标签(图3.3.3)。

Generate a picking list

The system team members will group the assigned wave orders according to certain rules (such as merging picking orders from the same recipient or merging picking orders from the same shipper), and print and generate corresponding grouping labels (Figure 3.3.3).

任务领用

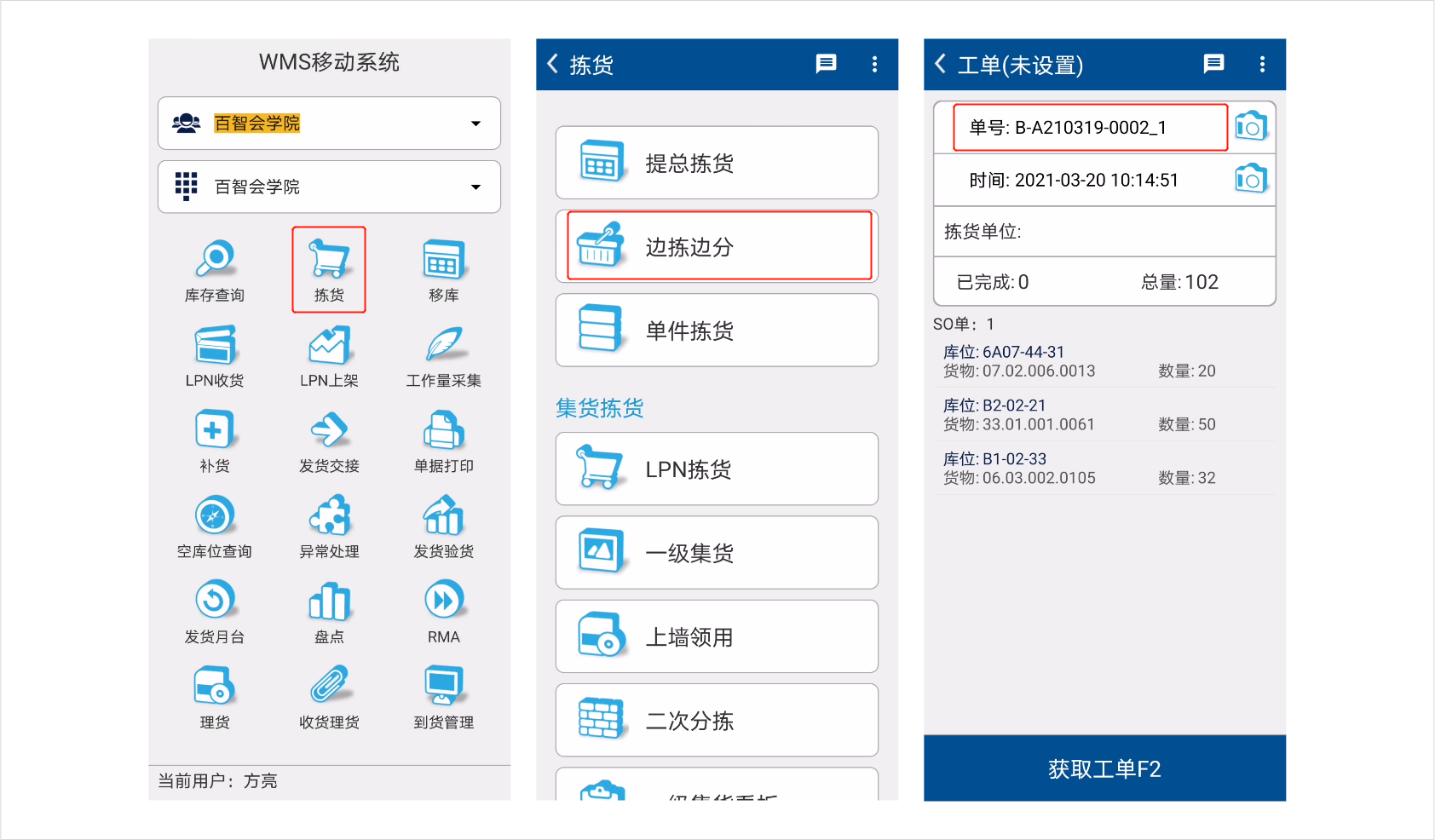

系统组员将打印的拣货工单,交接给拣货组长,拣货组长按工作量平均分配给相应的拣货组员。拣货组员在RF枪首页点击进入【拣货】,选择相应的拣货方式后,扫描分组标签(图3.3.3)上【工单号】对应的条码,系统会显示对应拣货任务明细,拣货工单领用完成(图3.3.4)。

Task requisition

The system team members will hand over the printed picking work order to the picking team leader, who will distribute the workload evenly among the corresponding picking team members. The picking team member clicks on "Picking" on the RF terminal homepage, selects the corresponding picking method, scans the barcode corresponding to the "Work Order Number" on the grouping label (Figure 3.3.3), and the system will display the corresponding picking task details. The picking work order has been collected and completed. (Figure 3.3.4)

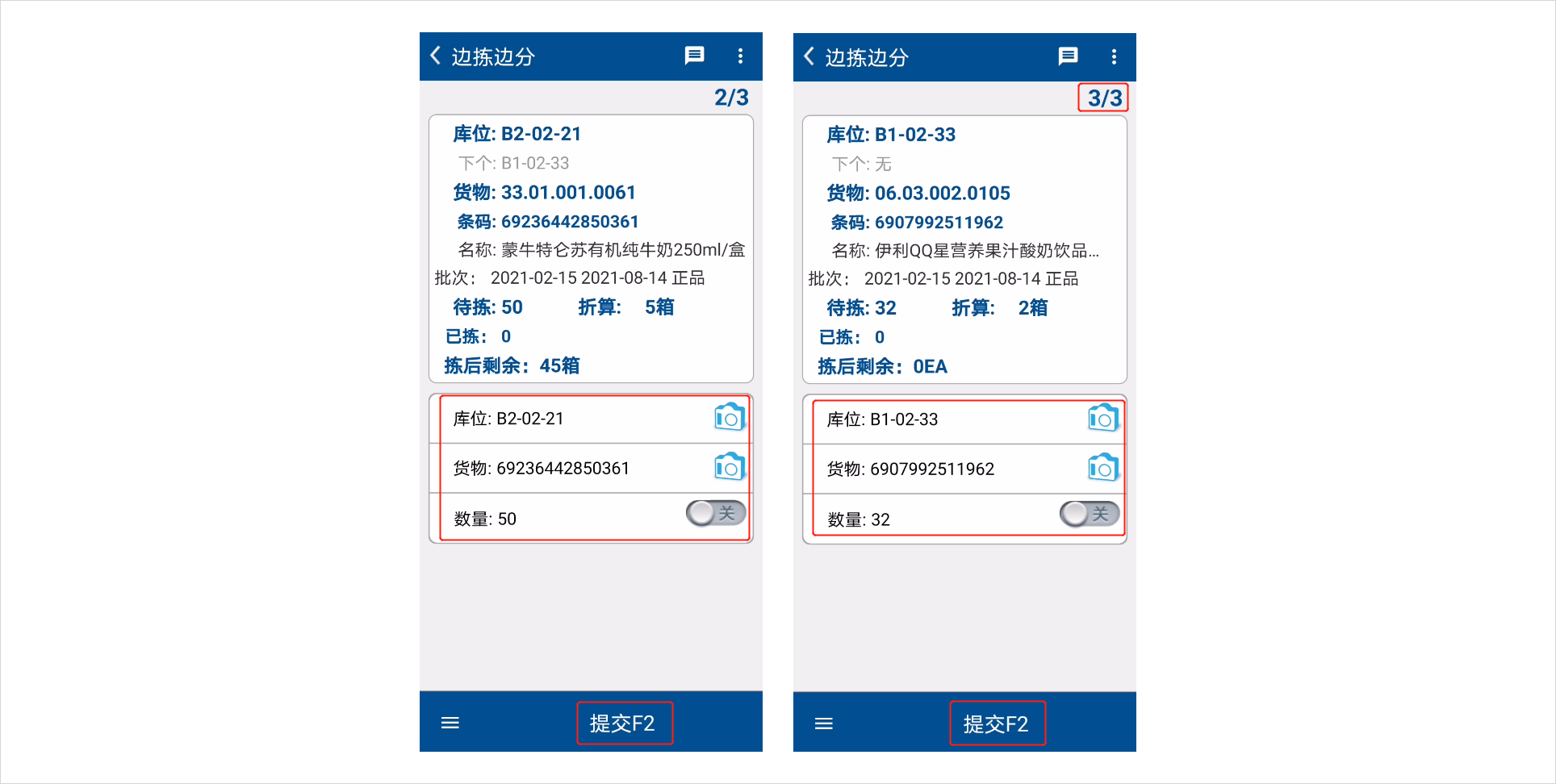

作业开始

拣货组员按照RF终端界面所指引的库位开始拣货。到达待拣货库位后,扫描拣货库位条码和商品条码,确认货物信息正确后,按照系统提示的拣货数量,将实物拣选至托盘或者中转箱。逐一拣选货物,直至系统提示工单全部完成(图3.3.5)。

Star of Operation

The picking team starts picking according to the inventory location indicated on the RF terminal interface. After arriving at the picking location, scan the barcode of the picking location and the barcode of the goods, confirm that the goods information is correct, and then pick the physical items onto pallets or transit boxes according to the picking quantity prompted by the system. Pick the goods one by one until the system prompts that all work orders are completed. (Figure 3.3.5)

货物转移

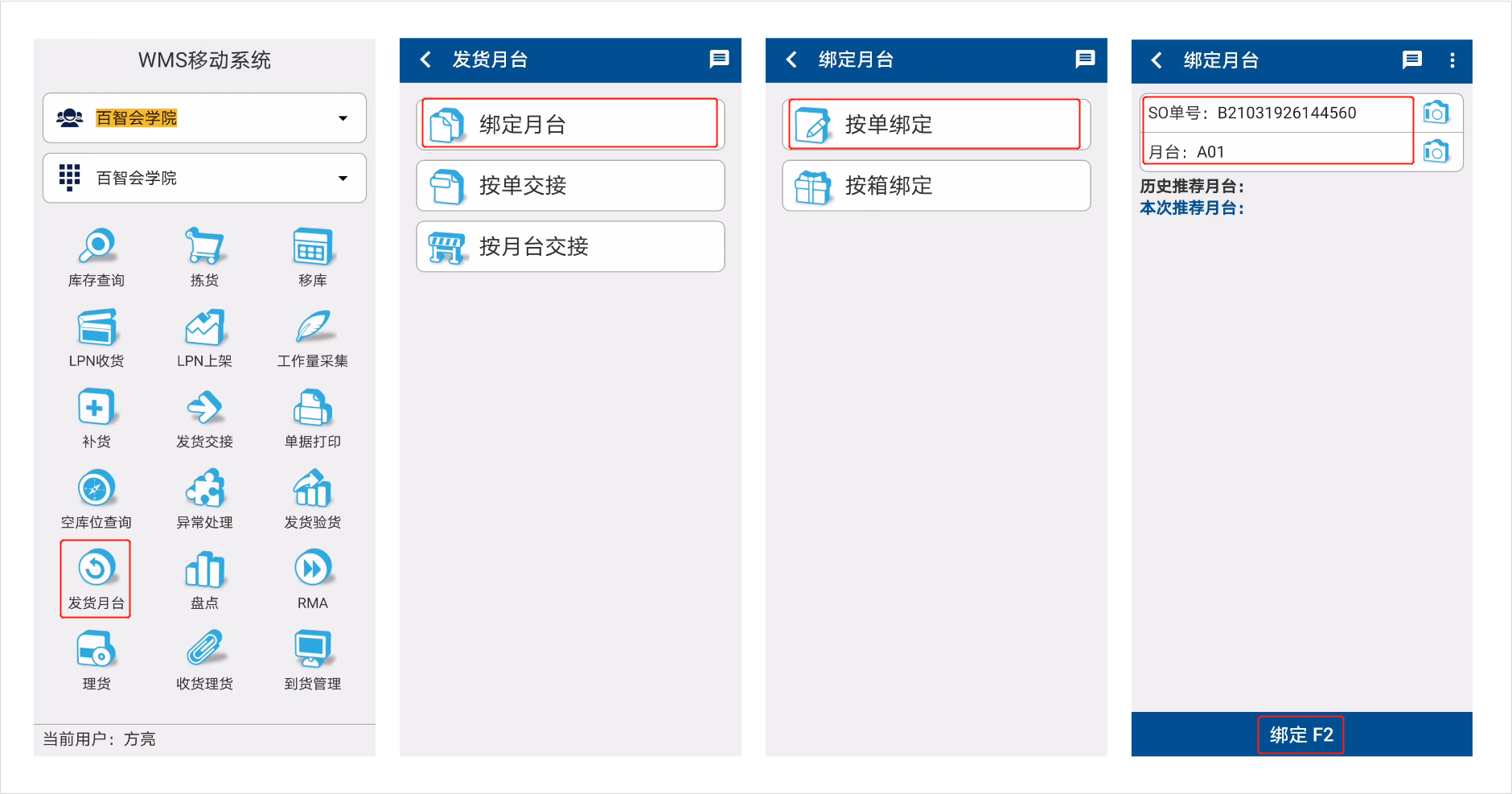

货物拣选完成后,拣货组员将订单货物和拣选单一同转移至发货暂存区的空闲月台(图3.3.6),并执行月台绑定操作,完成货物转移(图3.3.7)。

Transfer of goods

After the goods are picked, the picking team members transfer the order goods and picking list together to the vacant platform (Figure 3.3.6) in the shipping temporary storage area, and perform platform binding operations to complete the goods transfer (Figure 3.3.7).

作业完成

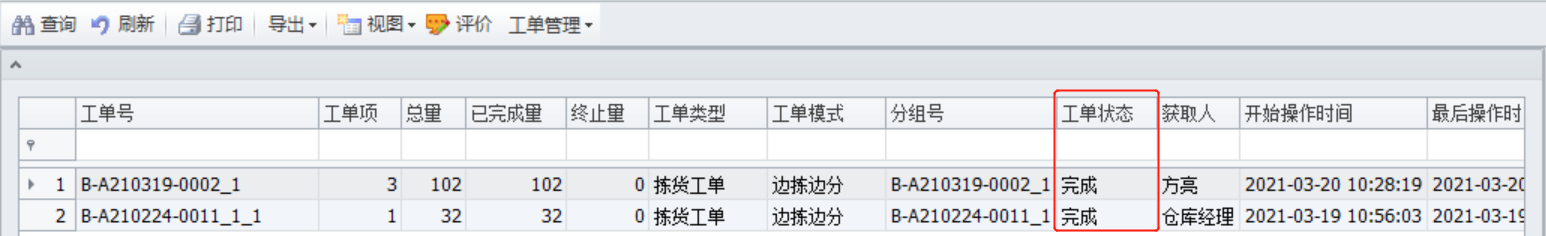

月台绑定后,拣货作业完成,拣货组员通知验货组员准备验货。拣货组长每天核查拣货工单完成情况(图3.3.8),保证当天拣货工单全部完成拣货。

Operation completion

After the platform is bound, the picking operation is completed, and the picking team notifies the inspection team to prepare for the inspection. The picking team leader checks the completion status of picking work orders every day to ensure that all picking work orders are completed on the same day. (Figure 3.3.8)

异常处理

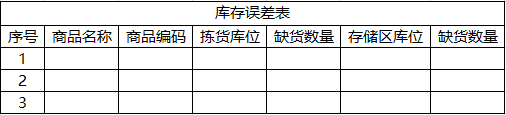

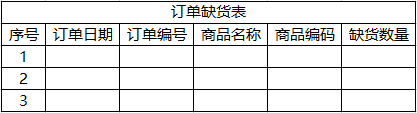

拣货组员拣货时可能会出现没有待拣货物或者待拣数量不足的情况。此时,首先应该确认是否发生货物漂移(货物错放至周边库位)。如果周围无法找到待拣货物,则可能是货物丢失,需上报拣货组长,协调库存组从存储区补货,并填写库存误差表(图3.3.9)。

如果存储区库存不足,则会造成订单缺货,库存组员需上报库存组长,通知货主并填写订单缺货表(图3.3.10)。货主采购经理与客户做好沟通协调,确认缺货订单的处理方式。

Exception handling

Picking team members may encounter situations where there are no goods to be picked or the quantity to be picked is insufficient. At this point, the first thing to confirm is whether there has been any cargo drift (goods mistakenly placed in nearby inventory locations). If the goods to be picked cannot be found around, it may be a loss of goods. It is necessary to report to the picking team leader, coordinate with the inventory team to replenish from the storage area, and fill out the inventory error table(Figure 3.3.9).

If the inventory in the storage area is insufficient, it will cause a shortage of orders. The inventory team member needs to report to the inventory team leader, notify the shipper, and fill out the order shortage form (Figure 3.3.10). The purchasing manager of the shipper should communicate and coordinate with the customer to confirm the handling method for out-of-stock orders.

专业核心词汇 Vocabulary

波次订单 wave order

拣货工单 picking work order

月台 platform

订单缺货表 order shortage table

发货暂存区 temporary storage area for shipment

学习拓展 Further Reading

百世企业货物拣选规定(参考)

1.整箱拣选要求货物重不压轻,大不压小,整齐码放,同种货物整齐摆放在一起,商品条码向外,方便扫描。

2.散件拣入容器中,同种货物需整齐摆放在一起,禁止混放、乱放。

3.整托为同一批次的货物,拣选时必须逐层拣货,禁止就近就低拣货。

4.完成拣货后,需要将库位剩余货物整理整齐,同种货物整齐码放,禁止出现不同货物相互混杂放置。

拣货码放标准可参考图3.3.11。

BEST Goods Picking Regulations (Reference)

1.Full box picking requires the goods to be heavy but not light, large but not small, neatly stacked, with the same type of goods neatly placed together, and the product barcode facing outward for easy scanning.

2.When picking up loose items into containers, the same type of goods should be neatly placed together, and mixing or disorderly placement is prohibited.

3.When picking goods from the same batch, they must be picked layer by layer, and it is forbidden to pick goods from the nearest batch.

4.After completing the picking process, it is necessary to tidy up the remaining goods in the inventory location, stack the same type of goods neatly, and prohibit the mixing of different goods.

The picking and stacking standard can refer to Figure 3.3.11.

知识巩固 Consolidation

选择题

上图3.3.12中的标志指示的是( )。

A. 发货暂存区

B. 收货暂存区

C. 理货区

D. 存储区

答案:A2.【WMS】接收客户ERP系统的发货订单时,生成的【WMS】内的唯一识别单号,被称为( )。

A.波次单号

B.OS单号

C.SO单号

D.LPN单号

答案:C3.拣货订单是基于( )生成的。

A.发货订单

B.波次订单

C.拣选单

D.货位顺序

答案:A填空题

上图3.3.13中库位B20221需要拣选的商品数量是( ),库位B010233需要拣选的商品数量是( ),两个库位一共需要拣选的商品数量为( )

答案:50 32 82判断题

在拣货中如果发现有货品库存不足,则应该将该订单取消。( )

答案:×技能训练

训练任务 完成拣货操作

【训练目标】

熟悉拣货作业工作流程并能够按照拣货标准流程规范完成拣货。

【训练内容】

背景资料

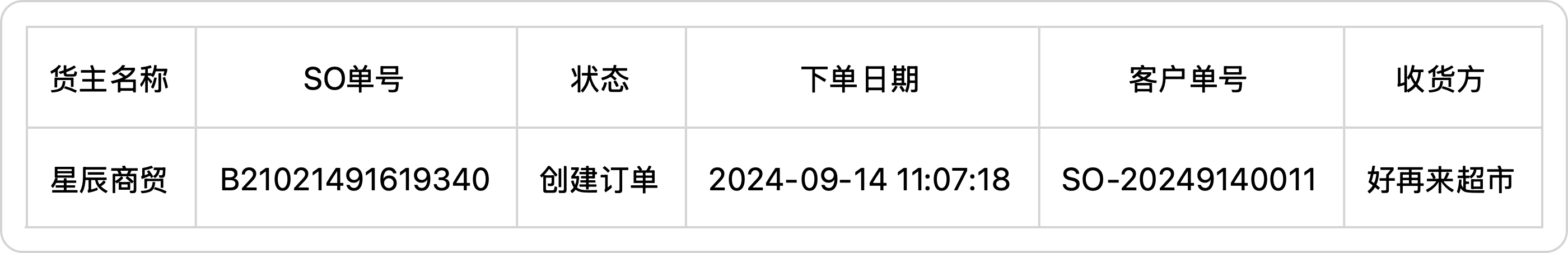

星辰商贸在【ERP】创建了一份销售订单,具体信息如下:

系统组员登录【WMS】系统,收到一份发货订单(表3.3.3):

请以小组为单位,分配岗位角色,模拟完成如下拣货作业。

(1)客户订单处理。

(2)领取拣货任务。

(3)执行拣货操作。

(4)粘贴分组标签。

(5)执行月台绑定操作。

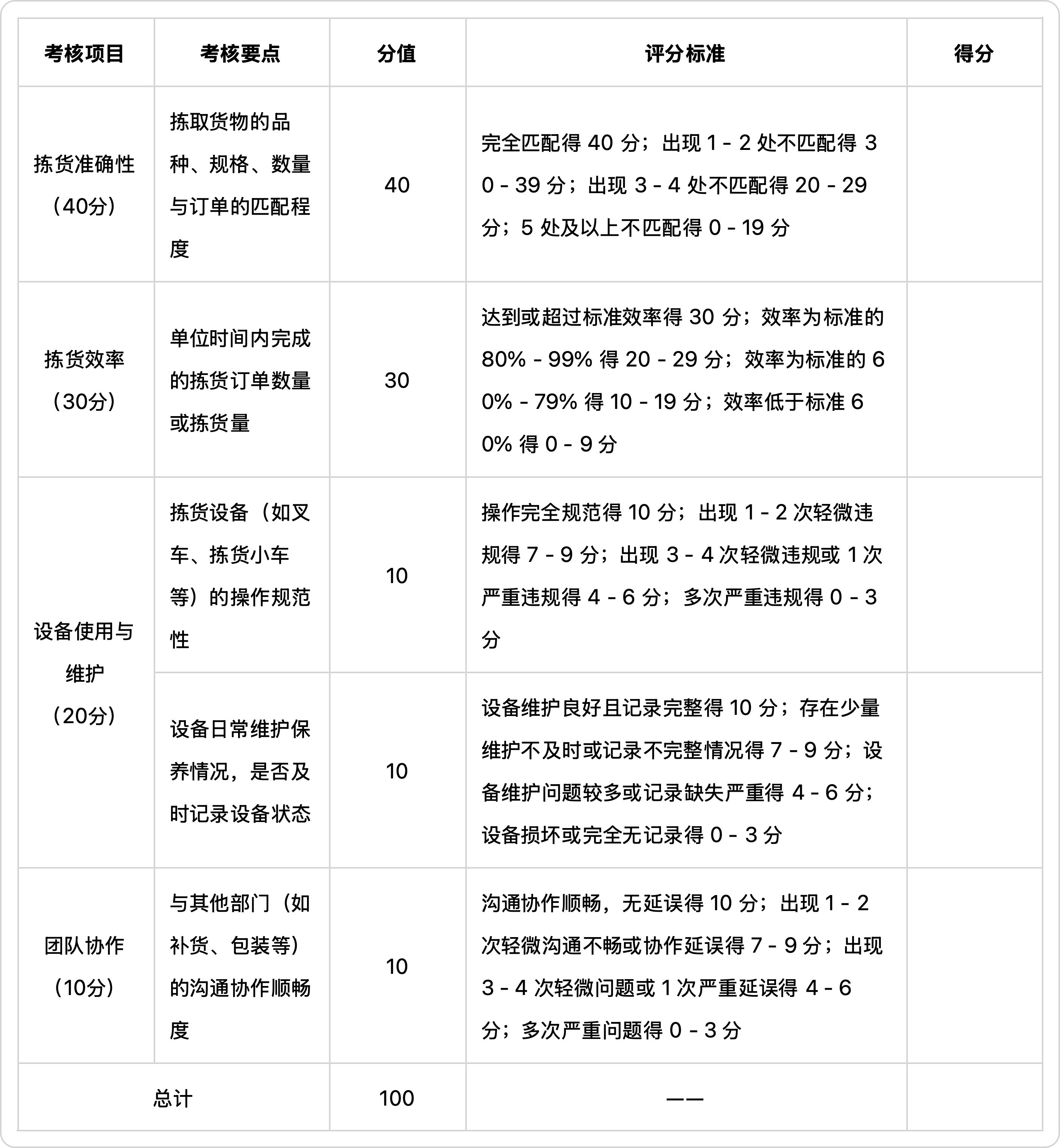

【考核评价】

操作日期: 年 月 日

微课

拣货作业

工作视频

拣货作业-1工具准备

拣货作业-2系统操作

拣货作业-3异常处理

课件

任务小结

本节课学习任务要点梳理如表3.3.5所示: