任务4 盘点作业

Task Four Stocktaking Operation

任务导入 Lead-in

库存组张组长:小李,上周入库的那批货物进行盘点了吗

库存组员李伟:组长,按照计划,今天下午将会对那批货物进行盘点。

库存组张组长:注意一定要仔细认真,不能目测估计数量。

库存组员李伟:组长您放心,我们一定会实盘实点,不会出现漏盘少盘多盘的情况,保质保量地完成任务。

库存组张组长:盘点作业完成后,不要忘记导出库存差异明细表,反馈给我。

库存组员李伟:好的组长,我们会及时向您反馈盘点进度和结果。

Leader Zhang Of Inventory Team: Xiao Li, has the batch of goods in the warehouse been counted last week?

Member Li Wei of Inventory team: Team leader, according to the plan, the goods will be counted this afternoon.

Leader Zhang Of Inventory Team: Note that you must be careful and serious, and you can't visually inspect or estimate the quantity.

Member Li Wei of Inventory team: Team leader, you can rest assured that we will definitely check the goods carefully and complete the task with quality and quantity.

Leader Zhang Of Inventory Team: After the stocktaking operation is completed, don't forget to export the inventory variance list and give me feedback.

Member Li Wei of Inventory team: Okay team leader, we will give you feedback on the progress and results of the inventory in a timely manner.

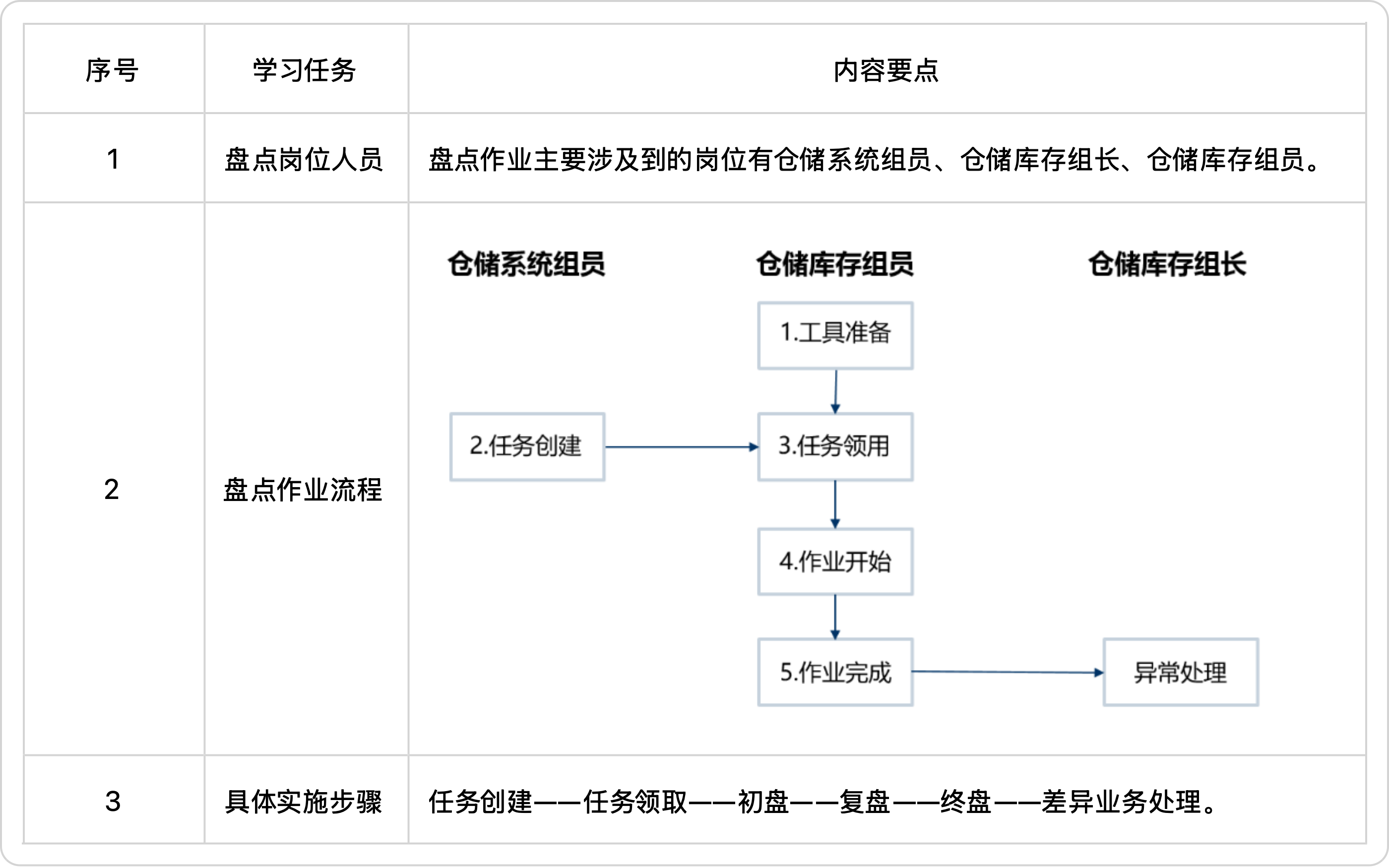

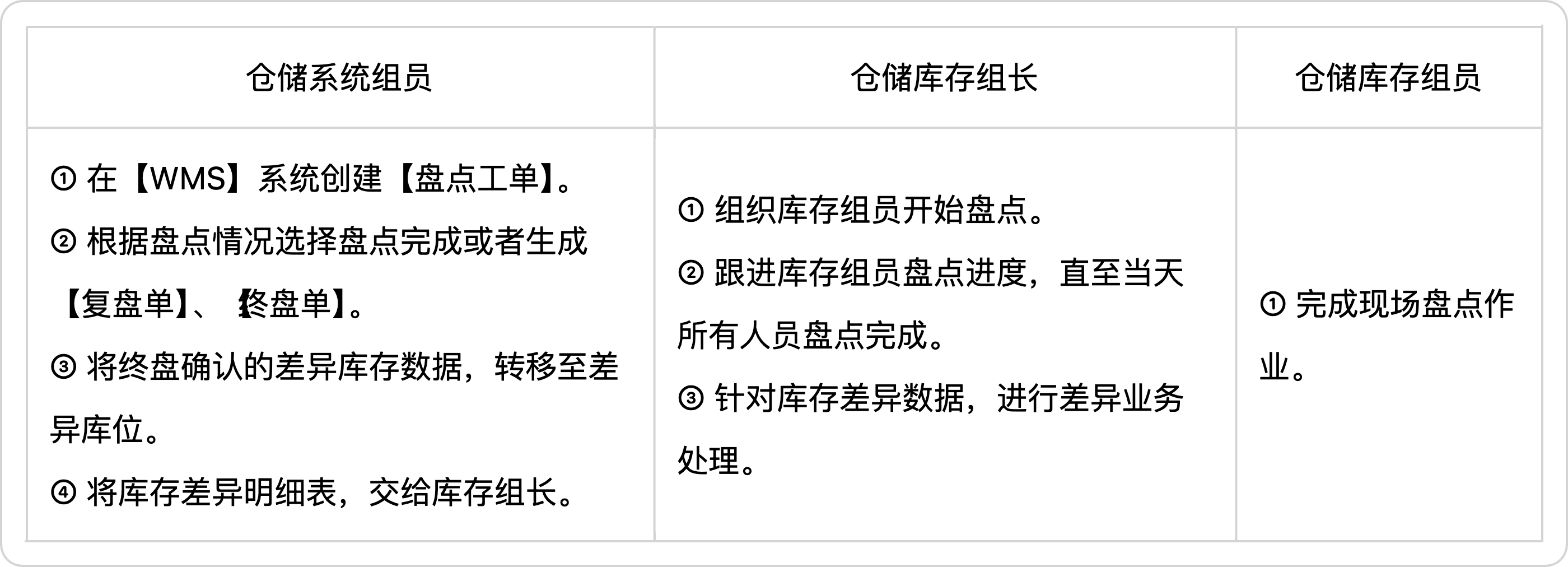

盘点岗位人员及其职责 Stocktaking Personnel and Their Responsibilities

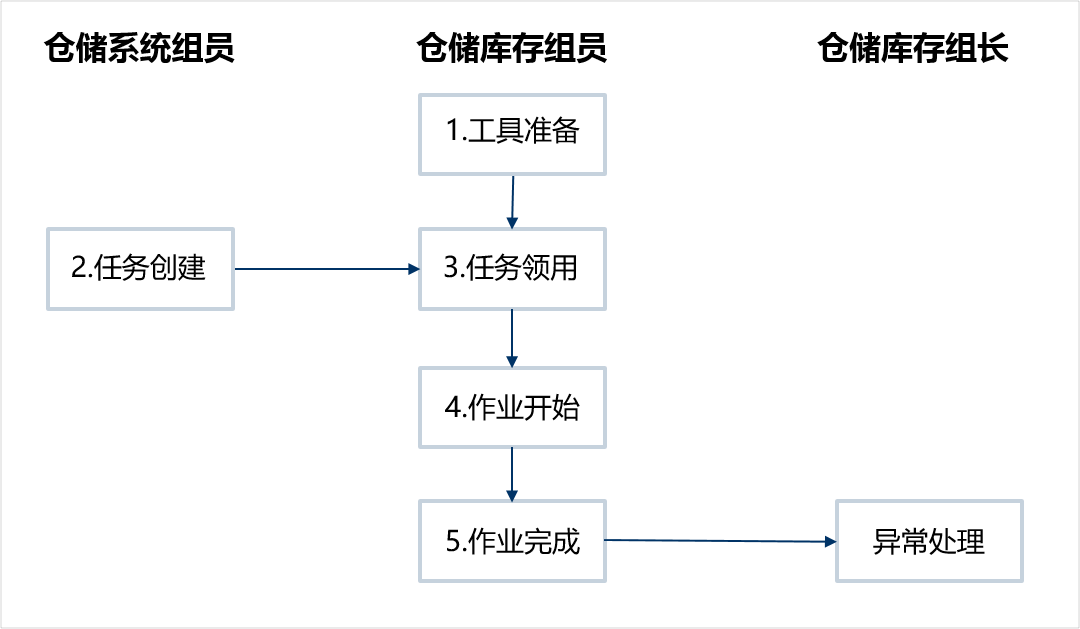

盘点作业流程 Stocktaking Process

具体实施步骤 Specific Implementation Steps

任务创建

系统组员创建盘点单

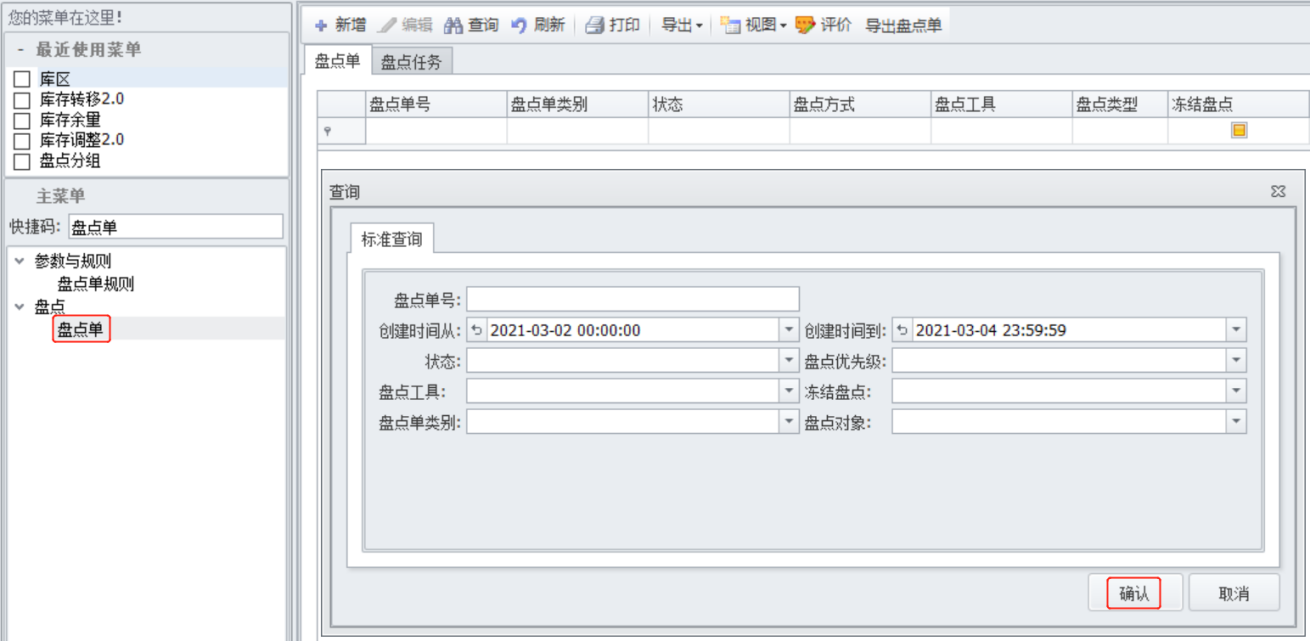

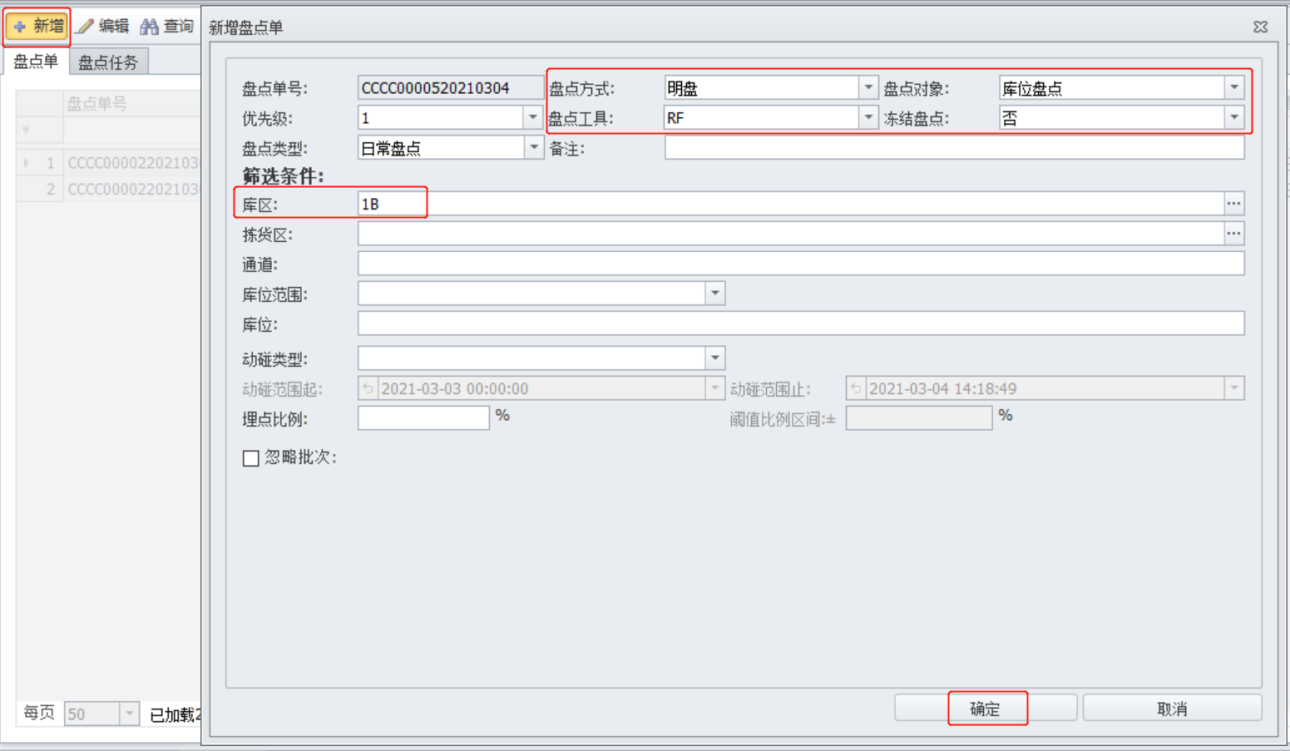

在电脑【WMS】菜单栏打开【盘点单】,在【查询】界面点击【确认】后,进入盘点单界面,点击【新增】,在【盘点方式】处选择【明盘】,在【盘点对象】处选择【库位盘点】,在【盘点工具】处选择【RF】。在【筛选条件】的【库区】处选择需本次盘点的库区。点击【确定】,生成盘点单。(图2.4.2、图2.4.3)

Task creation

System team members to create an inventory sheet

Open the [Stocktaking Sheet] in the [WMS] menu bar of the computer, click [confirm] in the [query] interface, enter the inventory sheet interface, click [Add], select [Open Count] at [Stocktaking Method], select [Bin Location Stocktaking] at [Stocktaking Object], and select [RF] at [Stocktaking Tool]. Select the reservoir area for this inventory at the [Reservoir Area] of the [Screening Conditions]. Click [OK] to generate the stocktaking sheet.(Fig. 2.4.2, Fig. 2.4.3)

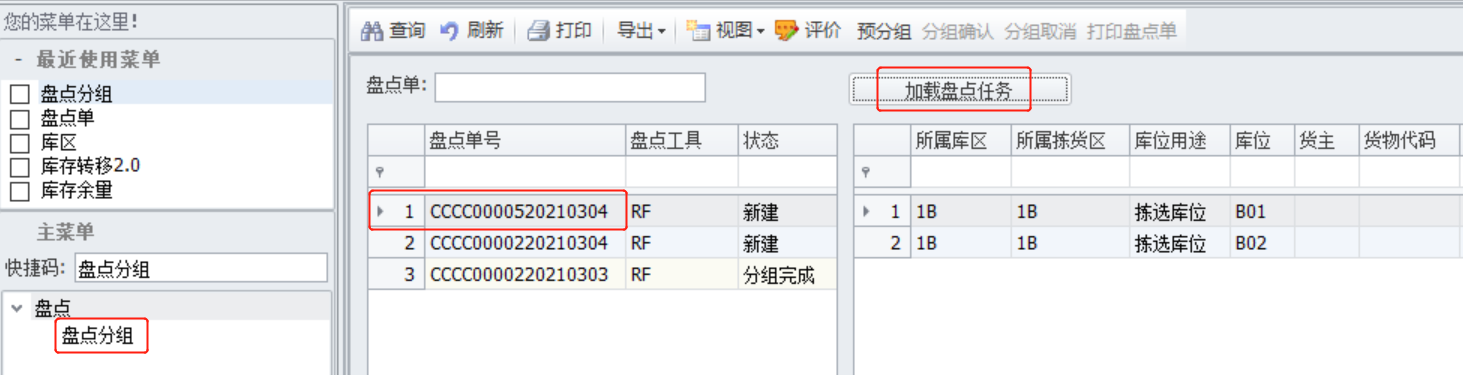

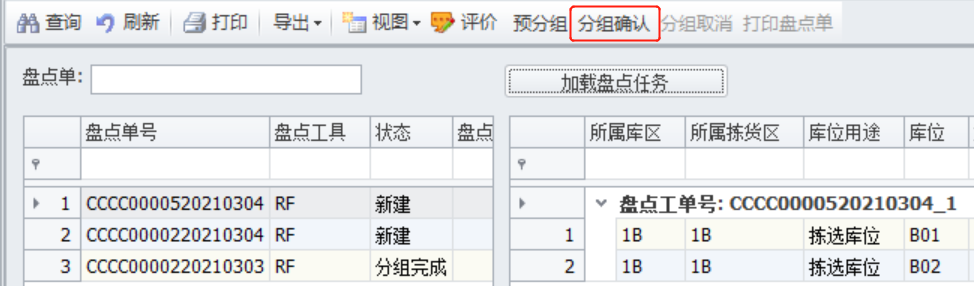

系统组员进行盘点工单分组。

在菜单栏选择【盘点分组】,选中已生成的盘点单,点击【加载盘点任务】,预览盘点任务明细,点击【预分组】,在弹出的【分组/排序条件】界面中勾选【排序条件】-【库位路线】选择【升序】,在【每组最大盘点库位数】处填写数量(例如5),点击【确定】,随后点击【分组确认】,完成盘点工单分组操作。(图2.4.4、图2.4.5、图2.4.6)

System team members divide stocktaking work orders into groups.

In the menu bar, select the generated stocktaking sheet [Stocktaking Group], click [Load Stocktaking Task], preview Stocktaking task details, click [Group], in the [Group / Sorting Conditions] interface check [Sorting Conditions] - [Sequence], in [Each Group of the Largest Stocktaking Number] to fill in the number (such as 5), click [Sure], then click [Group Confirm], complete the stocktaking order grouping operation.(Figure 2.6.4,2.6.5,2.6.6)

任务领取

1.库存组长组织库存组员开始盘点,库存组员在RF枪上领取盘点任务。

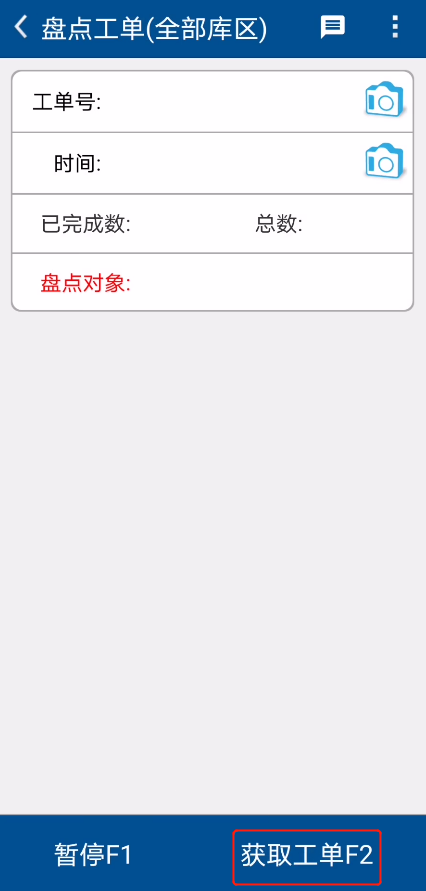

RF枪操作步骤:在首页选择【盘点】,进入【盘点】界面选择【初盘】,在【盘点工单】界面点击【获取工单F2】,即领取一张盘点工单任务。(图2.4.7、图2.4.8、图2.4.9)

Task collection

1.The inventory team leader organizes the stocktaking team members to start the inventory, and the stocktaking team members shall receive the task on the RF terminal.

Operation steps of the RF terminal:

Select [inventory] on the home page, enter the [inventory] interface to select [initial disk], click [get work order F2] on the [inventory work order] interface, that is, to get an inventory work order task.(Figure 2.4.7, Figure 2.4.8, Figure 2.4.9)

作业开始

1.在生成的盘点工单中点击盘点明细首行,开始盘点。(图2.4.10)

2.库存组员根据首行信息找到目标库位。(图2.4.11)

Start of operation

1.Click the first line of the stocktaking details in the generated stocktaking work order to start the operation.(Figure 2.4.10)

2.Inventory team members can find the target warehouse location according to the first line of information.( Figure 2.4.11)

①在【库位】处扫描盘点库位条码。

在【货物】处扫描商品条码,核对实物信息与系统显示是否一致,并在【整箱数、散件数】处分别输入盘点数量,点击【回车】。

如果该库位上有多种货物,在【货物】处扫描下一个货物条码,清点并输入数量后,点击【回车】,直至该库位上所有货物盘点完成。点击【提交F2】。(图2.4.12)

②重复以上动作,直至领取的工单所有库位盘点完成,此工单盘点结束。

③RF枪返回【初盘】界面,获取下一工单,按照上述操作继续进行盘点。

④如需中止盘点作业,进行其它作业的,返回【盘点工单】界面,点击【暂停F1】。工单暂停后,该工单由其它人再次获取,继续盘点。(图2.4.13)

① Scan the inventory location bar-code at the [inventory location].

Scan the commodity bar code at the [Goods], check whether the physical information is consistent with the system display, and enter the inventory quantity at the [Number of Whole Boxes and Scattered Pieces] respectively, and click [Enter].

If there are many kinds of goods on the warehouse, scan the next goods bar code at the [Goods], count and enter the quantity, and click [Enter] until the inventory of all goods on the warehouse is completed. Click on [Submit F2].(Figure 2.4.12)

② Repeat the above actions until the inventory of all the work order is completed and the inventory of the work order is completed.

③ The RF terminal returns to the [Initial Check] interface to obtain the next work order, and continue to take inventory according to the above operation.

④ If you need to suspend the inventory operation and conduct other operations, return to the [Inventory Work Order] interface and click [Pause F1]. After the work order is suspended, the work order will be obtained again by others and continue to take inventory.(Figure 2.4.13)

3.库存组长跟进库存组员盘点进度,直至所有人员盘点完成。

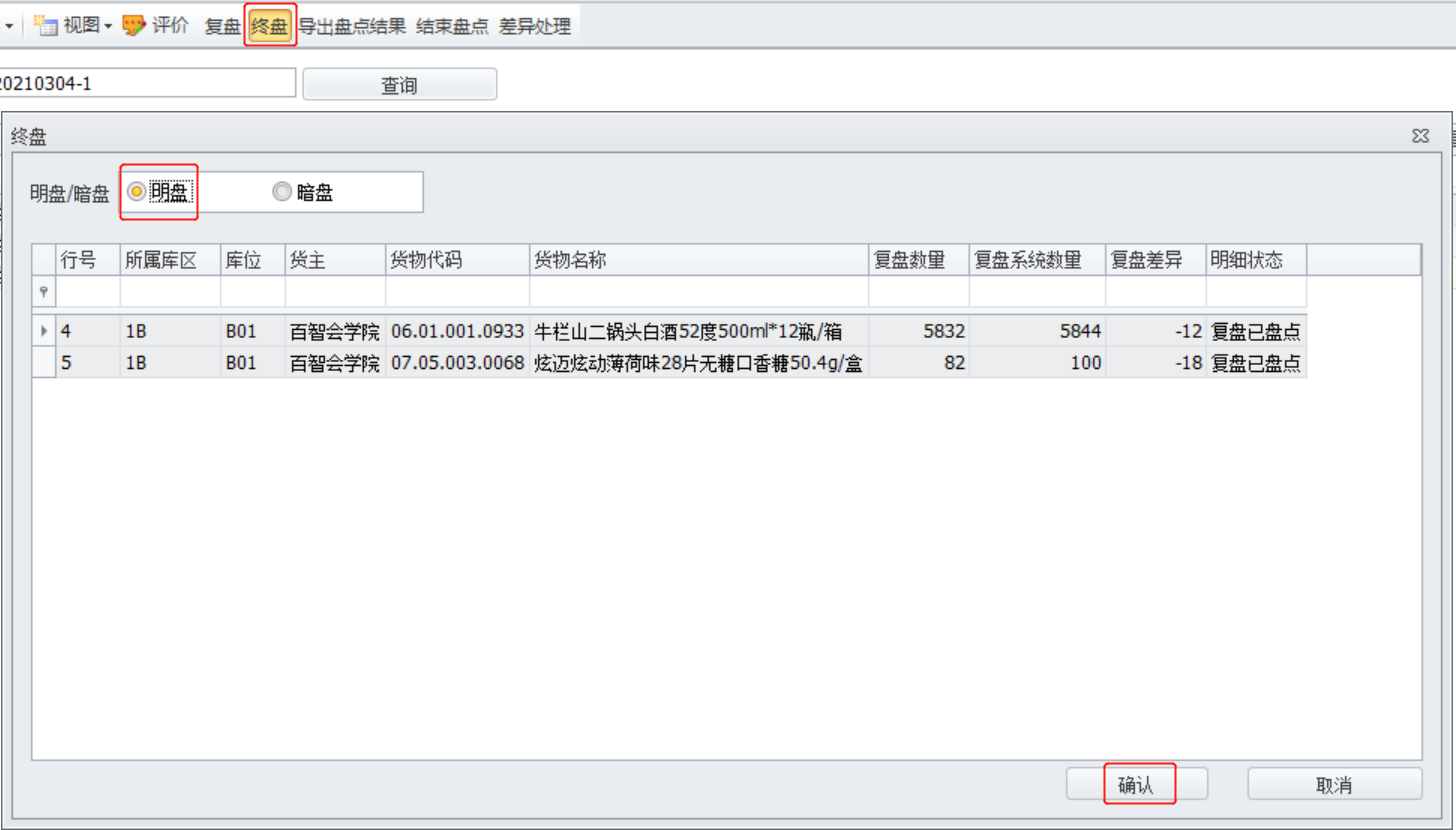

4.系统组员针对初盘单【完成】状态的盘点单,根据初盘结果选择盘点完成或者生成【复盘单】。

5.库存组长继续组织库存组员开始复盘。(复盘操作同初盘步骤)

6.库存组长跟进组员复盘进度,直至所有人员复盘完成。(同初盘检查步骤)

7.系统组员根据复盘情况选择复盘完成或者生成【终盘单】。(同复盘单生成步骤)(图2.4.14)

3.The inventory team leader follows up the inventory progress of the inventory team members until all the inventory is completed.

4.The team members of the system shall select the [Completion] or generate the [Review Order] according to the results of the initial order.

5.The inventory team leader continues to organize the inventory team members to start the review.(The recovery operation is the initial step)

6.The inventory leader follows up the review progress of the team members until all the personnel complete the review.(Same as the initial check inspection step)

7.The system team members choose the review to complete or generate [Final Check] according to the review situation.(Generation step) (Figure 2.4.14)

8.直至终盘完成,如存在差异的,由库存组长针对货物进行复核,确认最终差异后,在系统中【结束盘点】。

9.盘点结束后,对差异数据进行处理。

系统组员在盘点完成后,需将差异库存数量由原库位转移至差异库位。

8.Until the completion of the final check, if there is any difference, the inventory leader will check the goods, confirm the final difference, and click [End Inventory] in the system.

9.After the stocktaking operation, process the difference data.

After the stocktaking operation, the system team members shall transfer the differential inventory location from the original inventory location to the differential inventory location.

作业完成

盘点作业完成。系统组员导出库存差异明细表,反馈至库存组长,库存组长进行下一步差异业务处理。

Operation completion

The stocktaking operation is completed. The system team members export the inventory difference list and feedback it to the inventory leader for the next difference business processing.

专业核心词汇 Vocabulary

盘点 stocktaking

库存 inventory

库区 warehouse area

库位 inventory location

初盘 initial check

复盘 review

差异 difference

终盘 final check

学习拓展 Further Reading

盘点时间的决定

一般性货物就账实相符的目标而言盘点次数愈多愈好,但因每次实施盘点必须投入人力、物力、财力,这些成本耗资不少,所以要控制盘点次数。事实上,导致盘点误差的关键原因是在于出入库的过程,可能是因出入库单据的输入、检查点数的错误、或是出入库搬运造成的损失,因此一旦出入库作业次数多时,误差也会随之增加。所以,对一般生产企业仓库而言,其货物流动速度不快,半年至一年实施一次盘点即可。但对物流中心、配送中心仓库,在货物流动速度较快的情况下,我们既要防止过久盘点对公司造成的损失,又要节约盘点资源,因而最好能视物流中心各货物的性质制定不同的盘点时间。例如,在实施商品类别ABC管理的企业中,一般会建议:

(1)A类主要货物:每天或每周盘点一次。

(2)B类货物:每二、三周盘点一次。

(3)C类较不重要货物:每月盘点一次即可。

而未实施商品别ABC管理的企业,至少也应对较容易损耗毁坏及高单价之货物增加其盘点次数。另外应注意的是,当实施盘点作业时,时间应尽可能缩短,以1-2日内完成较佳。至于选择的日期一般会选择在:

(1)财务决算前夕方便计算损益以及表达财务状况。

(2)淡季进行──因淡季储货量少盘点容易,人力的损失相对降低,且调动人力较为便利。

The Decision of the Stocktaking Time

The more times the general goods are counted, the better for the purpose of meeting the actual stocktaking objectives. But because each implementation of the operation must invest manpower, material resources, financial resources, these cost a lot, so we should control the number of inventory. In fact, the key reason for the inventory error is the process of entry and exit, which may be due to the input of the documents, the error of check points, or the loss caused by warehousing and handling. Therefore, once the number of entry and exit operation is long, the error will also increase. Therefore, for the general production enterprise warehouse, the flow speed of its goods is not fast, half a year to a year an inventory can be implemented. However, for the logistics center and distribution center warehouse, with the fast flow of goods, we should not only prevent the loss caused by excessive inventory to the company, but also save the inventory resources. Therefore, it is best to schedule different inventory time according to the nature of each goods in the logistics center. For example, in enterprises implementing ABC management of commodity category, it is generally recommended as follows:

(1) Class A main goods: daily or weekly.

(2) Class B goods: every two or three weeks.

(3) Class C unimportant goods: once a month.

Enterprises that do not implement commodity ABC management should at least increase the number of inventory counts of goods that are more prone to loss and damage and high unit price. In addition, it should be noted that when the inventory operation is implemented, the time should be as short as possible, and it is better to complete within 1-2 days. The date of selection is usually chosen as:

(1) It is convenient to calculate profits and losses and express financial status on the eve of financial accounts.

(2) Off-season - Because of the small amount of inventory in the off-season, the loss of manpower is relatively reduced, and the mobilization of manpower is more convenient.

知识巩固 Consolidation

排序题

以下词条为盘点作业具体步骤,如选择盘点库位明细为第一步,则用数字标明①,后续步骤请按照作业顺序依次进行编号。

选择盘点库位明细(①)

扫描商品条码( )

扫描盘点库位条码( )

输入盘点数量( )

核对实物信息( )

点击提交盘点结束( )

答案:①③②⑤④⑥选择题

1.在WMS系统中,盘点是按照( )进行盘点的。

A.库位

B.LPN码

C.托盘编号

D.商品编号

答案:A2.系统组员在盘点完成后,需将差异库存数量( )。

A.退回供应商

B.由原库位转移至差异库位

C.由差异库位转移至原库位

D.按照盘点结果在系统中进行修正

答案:B3.【WMS】系统盘点作业流程包括( )。

A.初盘

B.复盘

C.终盘

D.差异处理

答案:ABC判断题

1.WMS中,盘点方式可以分为明盘和暗盘两种。 ( )

答案:√2.在WMS系统中,按库位顺序盘点时必须按升序逐次盘点。( )

答案:×技能训练

训练任务 实施盘点作业

【训练目标】

1.熟悉【WMS】系统中创建【盘点单】的具体步骤。

2.能够根据条件生成【盘点工单】。

3.能够掌握盘点作业的基本技能,包括人员的组织安排盘点前的准备工作现场盘点和盘点结果处理等。

【训练内容】

请根据以上信息,完成盘点作业。

【训练步骤】

1.在【WMS】系统中创建【盘点单】,再根据条件生成【盘点工单】,完成盘点工单标签的打印。

2.根据所创建的盘点作业任务(盘点工单),在RF枪【WMS】系统获取盘点任务。

3.库存组员按照RF枪【盘点工单】明细,到指定库位开始盘点作业,并完成RF枪【WMS】系统盘点操作。

4.盘点作业完成后,库存组长进行下一步差异业务处理。

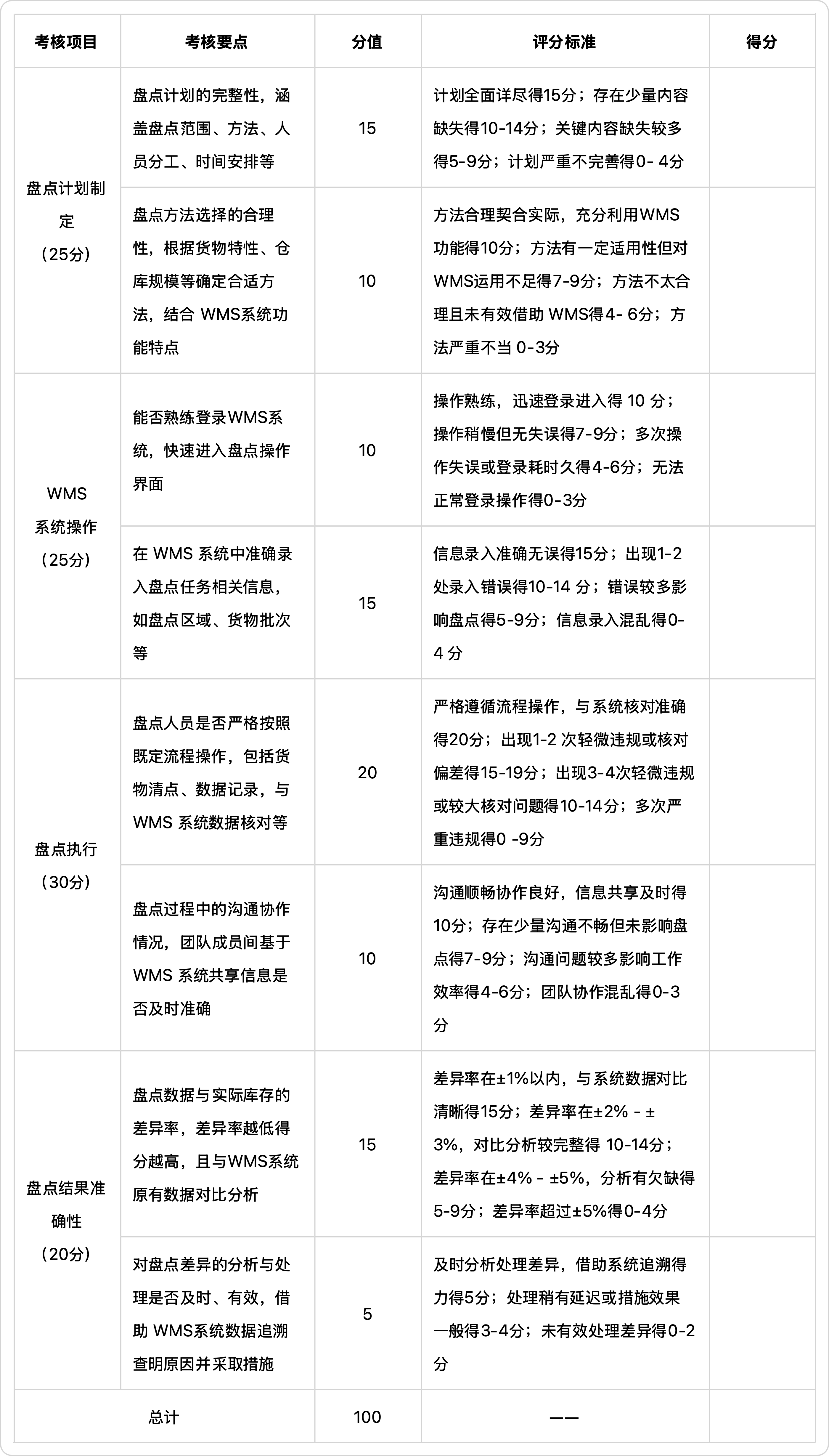

【考核评价】

微课

盘点作业认知

盘点作业工作流程-初盘

盘点作业工作流程-复盘终盘

工作视频

盘点作业——1工具准备

盘点作业——2系统操作

盘点作业——3异常处理

课件

任务小结

本节课学习任务要点梳理如表所示: