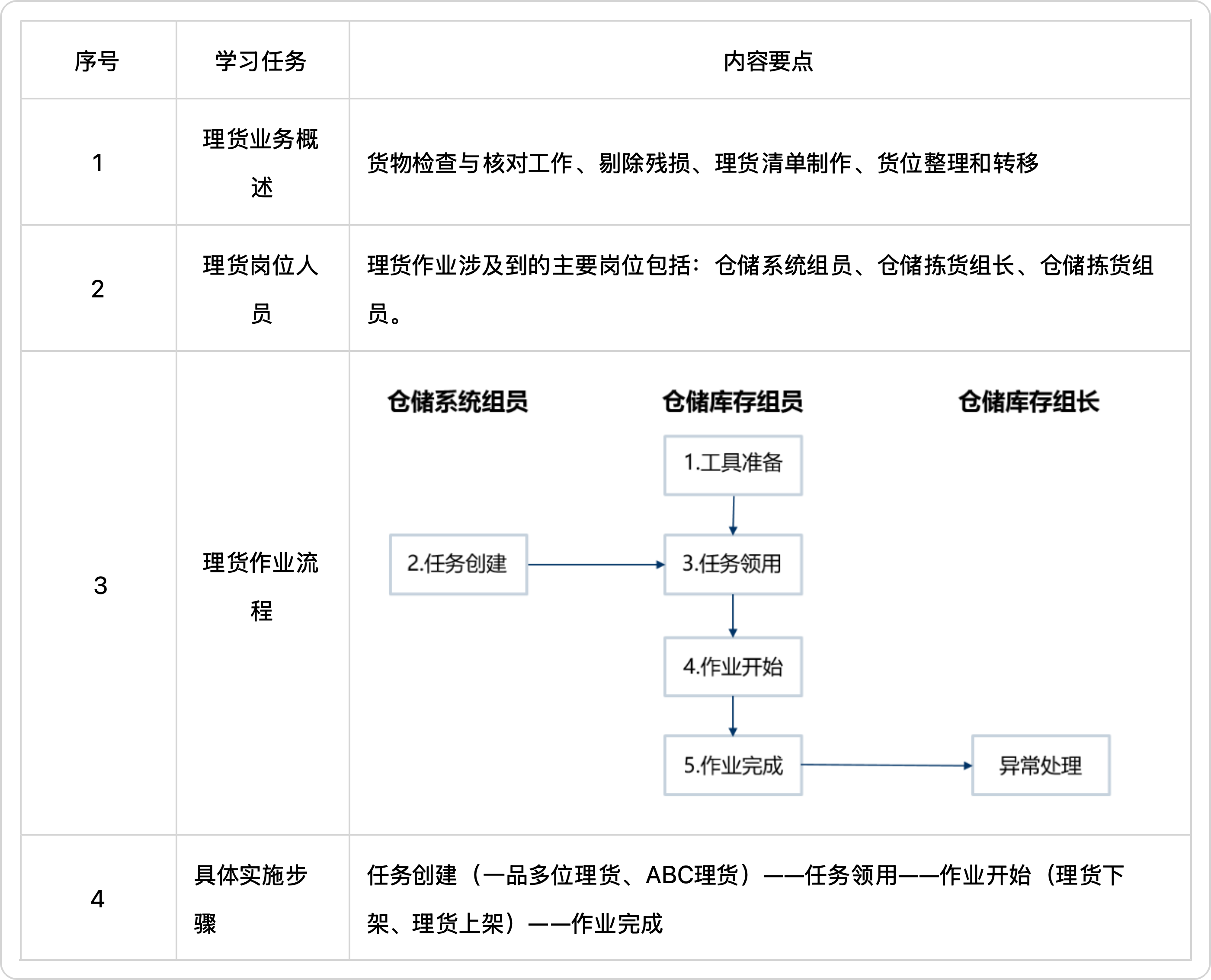

任务3 理货作业

Task Three Tally Operation

任务导入 Lead-in

库存组张组长:小李,上午入库的那批货物已完成苫垫,请务必做好理货作业,这可是入库的第一次检查

库存组员李伟:好的组长,我们一定会认真清点货物件数核对重量,检查好货物的表面状态。

库存组张组长:注意一旦发现货物外表状况不良,或者怀疑内容损坏,一定要将不良货物剔出,单独存放。

库存组员李伟:组长您放心,我们会及时剔除残损。

库存组张组长:好的,辛苦了。

Leader Zhang of Inventory team: Xiao Li, the batch of goods in the morning has been completed, please be sure to do a good job of tally operation. This is the first inspection of inbound operation!

Member Li Wei of Inventory Team: Okay team leader, we will carefully count the number of goods, check the weight, and check the surface condition of the goods.

Leader Zhang of Inventory team: Note that once the appearance of the goods is found to be in poor condition, or the content is suspected to be damaged, the bad goods must be eliminated and stored separately.

Member Li Wei of Inventory Team: Rest assured, team leader, we will remove the damage in time.

Leader Zhang of Inventory team: Okay, thank you for your hard work.

理货业务认知 The Cognition of the Tally Operation

仓库理货主要工作内容有:

货物检查与核对工作

(1)清点货物件数

(2)查验货物单重、尺度

(3)查验货物重量

(4)检验货物表面状态

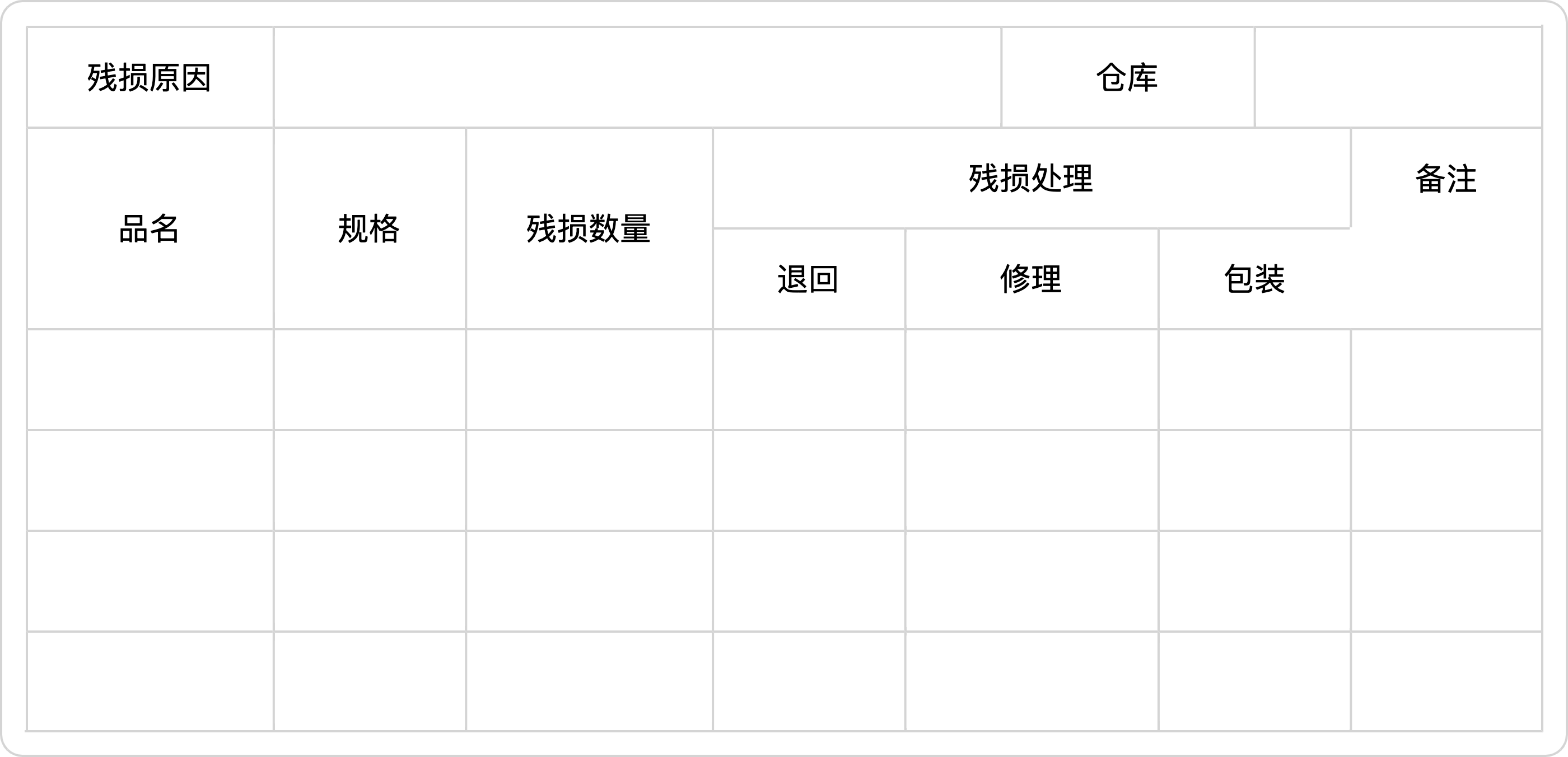

剔除残损

在理货时发现货物外表状况不良,或者怀疑内容损坏等,应将不良货物剔出,单独存放,避免与其他正常货物混淆。待理货工作结束后进行质量确定,确定内容有无受损以及受损程度。对不良货物可以采取退货、修理、重新包装等措施处理,或者制作残损报告,以便明确划分责任(表2.3.1)。

The main contents of warehouse tally are:

Goods inspection and verification

(1) Count the number of goods

(2) Check the unit weight and scale of the goods

(3) Check the weight of the goods

(4) Inspect the surface condition of the goods

Remove the damage

If the appearance of the goods is found to be in poor condition during tally operation, or the contents are suspected to be damaged, the defective goods should be removed and stored separately to avoid confusion with other normal goods. After the tally operation is completed, the quality is determined to determine whether the content is damaged and the extent of damage. Defective goods can be returned, repaired, repackaged, etc., or a damage report can be prepared so that responsibilities can be clearly divided (Table 2.3.1).

收货日期: 编号:

货主: 送货单号:

Receipt date: Number:

Shipper: Delivery note number:

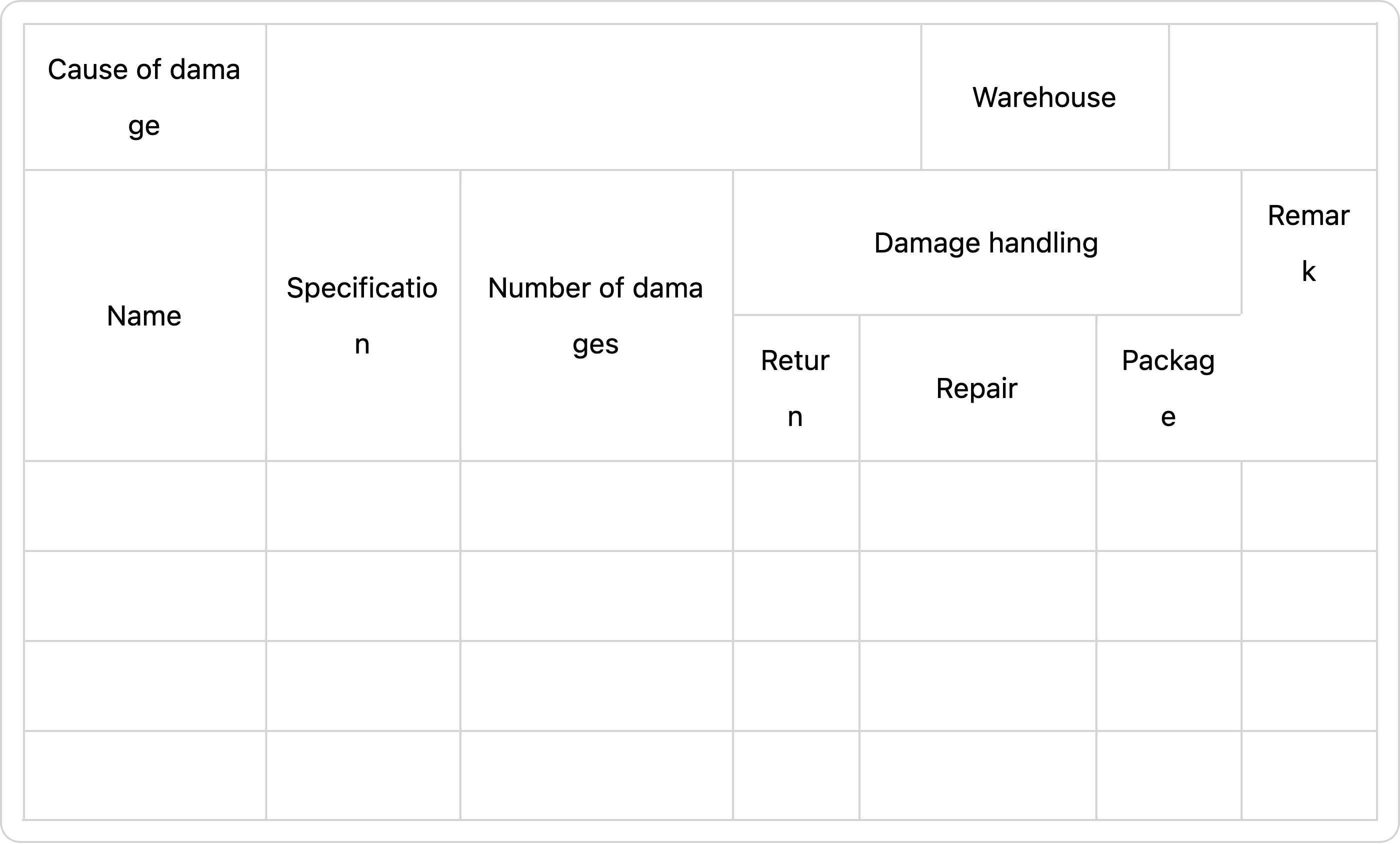

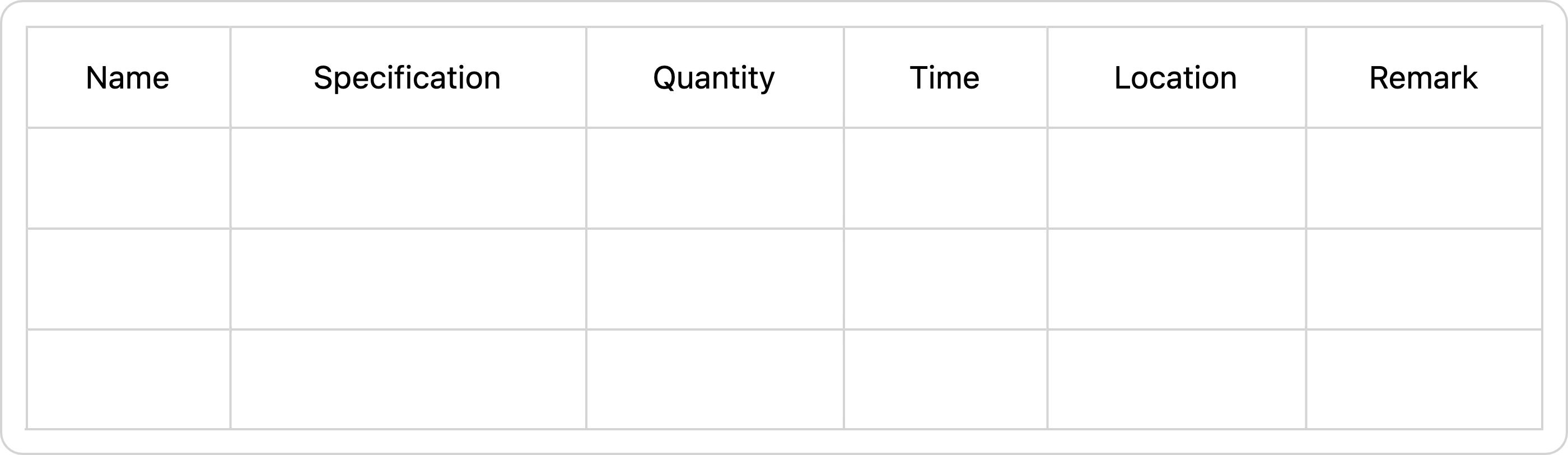

理货清单制作

理货人员根据每次理货的情况,填写理货清单,如表2.3.2所示

Tally list making

The tally staff fills in the tally list according to the situation of each tally, as shown in Table 2.3.2

货位整理和转移

理货人员在整理仓库时按照已划分好的区域、货架,将已经归类的物品进行定期的整理,检查物品是否摆放整齐,产品的等级是否过期,包装是否需要进行转换等工作。理货人员根据货物存放的需要对仓库的货品进行整理并进行储位的转移时,要做到账、卡、物相一致。

Sorting and transfer of goods locations

When sorting out the warehouse, the tally personnel will regularly sort out the items that have been classified according to the divided areas and shelves, check whether the items are placed neatly, whether the grade of the product is expired, and whether the packaging needs to be converted. When the tally personnel sort out the goods in the warehouse and transfer the storage location according to the needs of the goods storage, they should make the accounts, cards and things consistent.

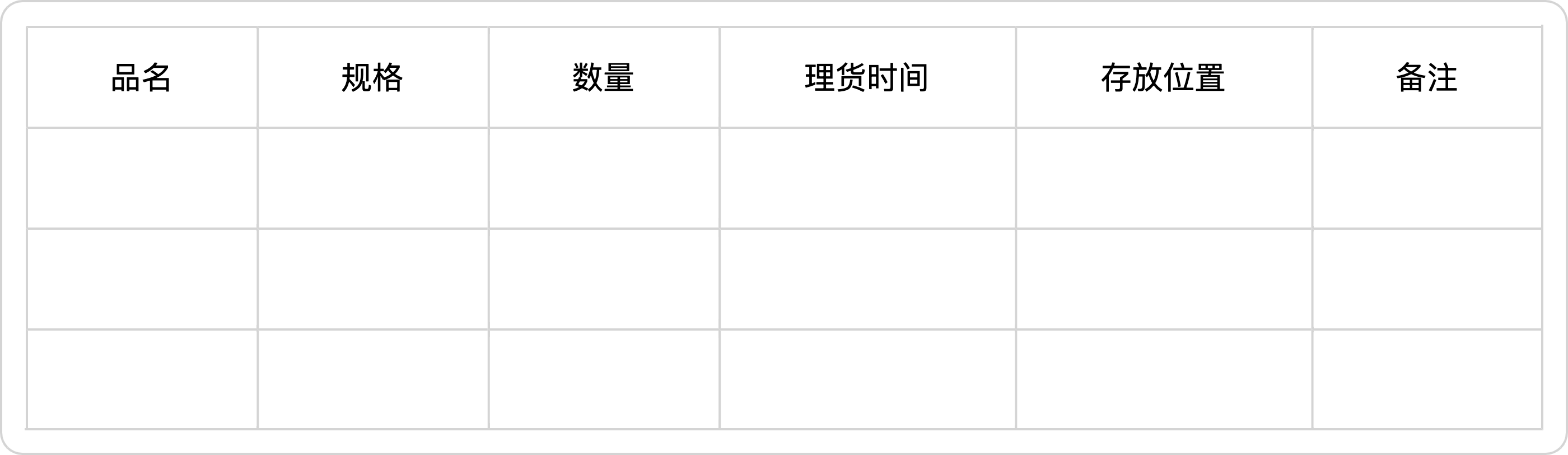

理货岗位人员及其职责 Tally Position Personnel and Their Responsibilities

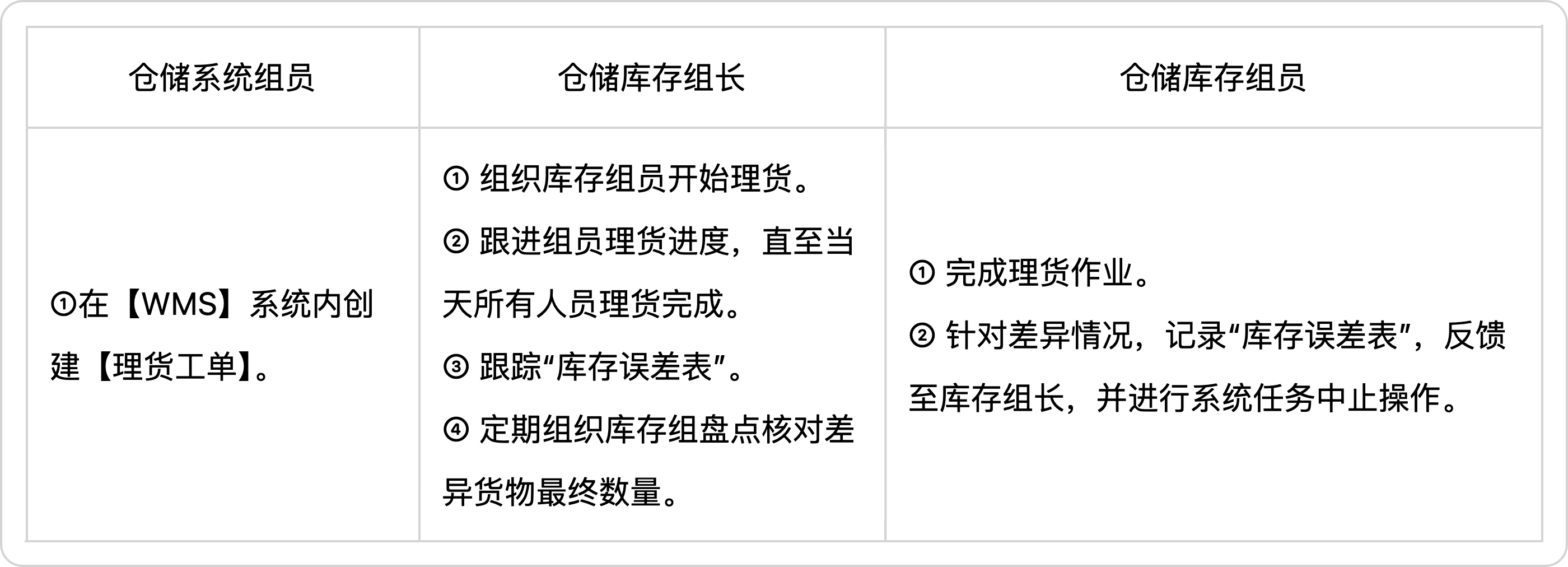

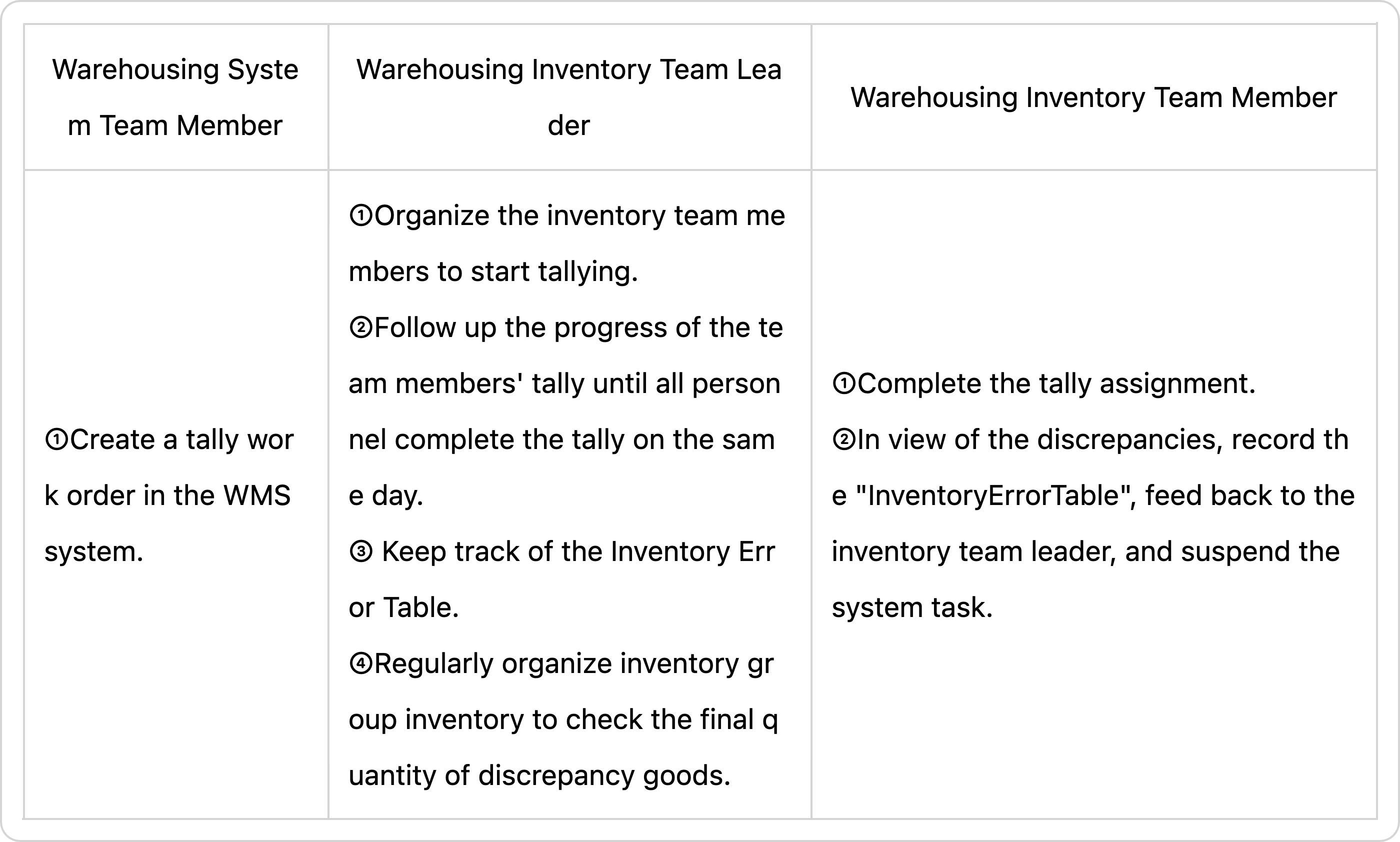

理货作业涉及到的主要岗位包括:仓储系统组员、仓储拣货组长、仓储拣货组员,各岗位主要工作内容如表2.3.3所示。

The main positions involved in the tally operation include: warehousing system team member, warehousing picking team leader, warehousing picking team member, and the main work content of each position is shown in Table 2.3.3.

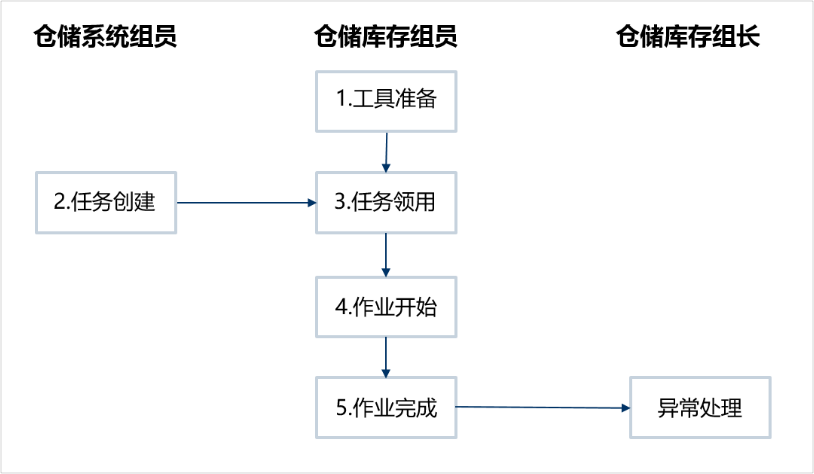

理货作业流程 Tally Operation Process

具体实施步骤 Specific Implementation Steps

任务创建

【WMS】支持2种理货方式,一品多位理货与ABC理货。两种理货方式的任务创建过程不同。

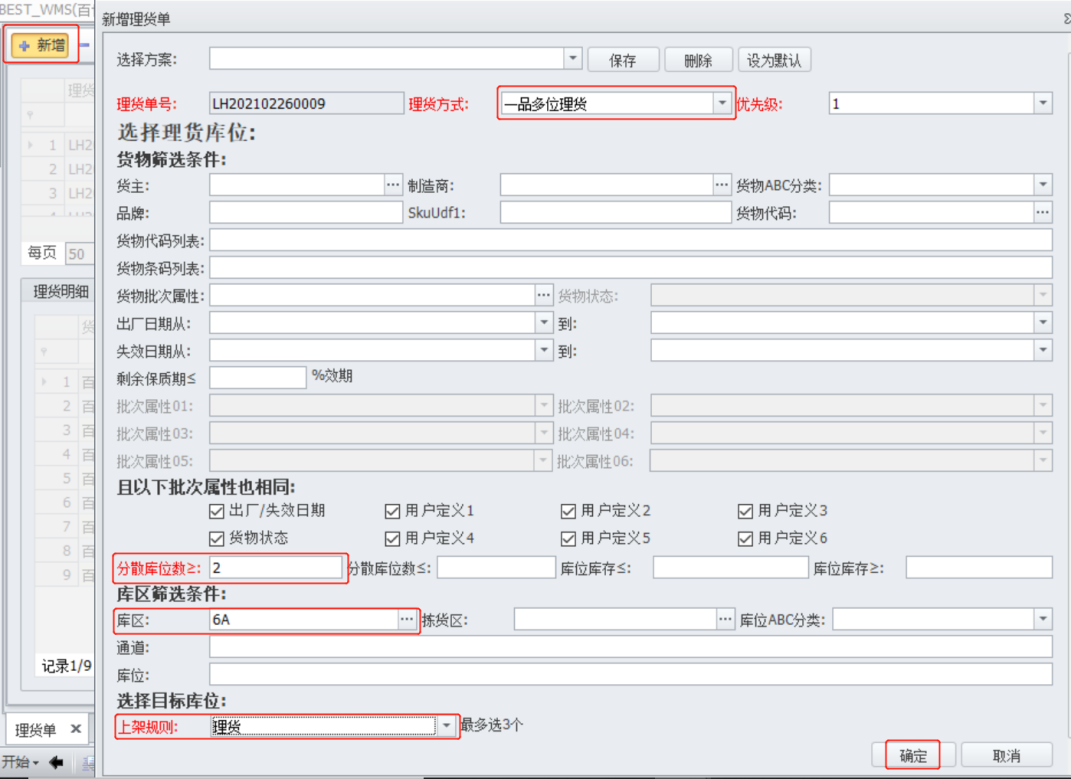

一品多位理货的任务创建

① 系统组员创建理货单

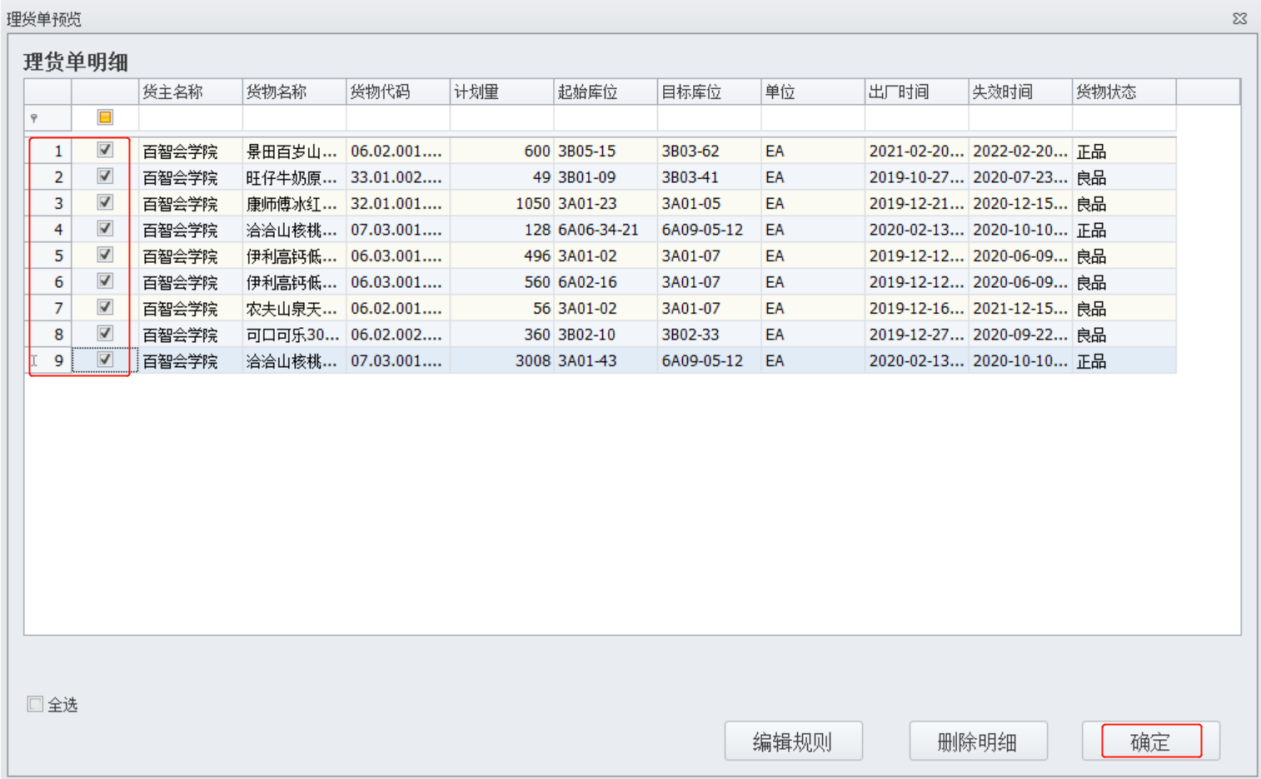

系统组员在电脑【WMS】的菜单栏中选择【理货单】。在【新增理货单】界面【理货方式】处选择【一品多位理货】,点击【确定】。在【理货单预览】界面选择全部理货单明细,生成理货单。(图2.3.2、图2.3.3)

Task creation

[WMS] supports 2 tally methods, one SKU multiple locations and ABC tally. The task creation process is different for the two tally methods.

Creation of tasks for multiple tally items in one product

① The system team member creates a tally list

The system team member selects [Tally] in the menu bar of the computer [WMS]. In the [New Tally List] interface, select [One Product Multi-Tally Method] and click [OK]. On the [Tally List Preview] page, select all tally list details to generate a tally list. (Figure 2.3.2, Figure 2.3.3)

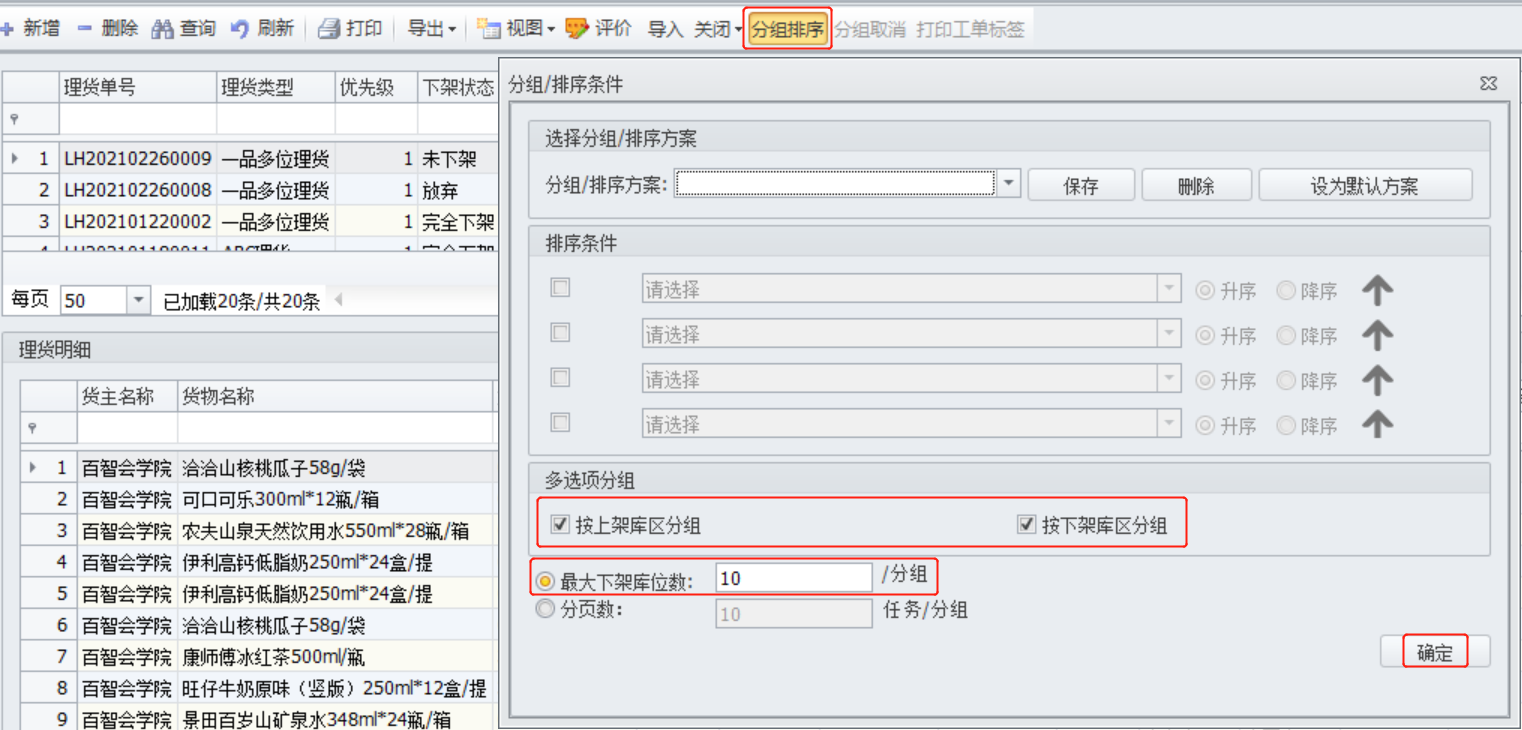

② 创建理货工单

在【理货单】界面选中生成的理货单,点击【分组排序】进行工单分组,在【分组/排序条件】界面配置分组条件。(图2.3.4)

② Create a tally work order

Select the generated [tally order] on the tally sheet page, click [Group Sort] to group the work order, and configure the grouping conditions on the [Group/Sort Condition] interface. (Figure 2.3.4)

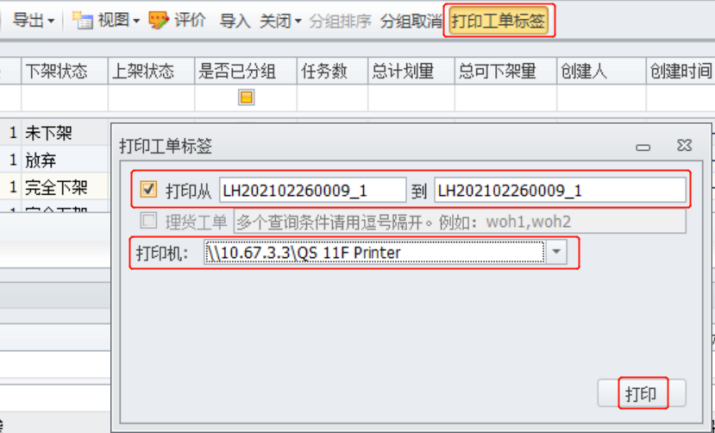

③ 打印理货工单标签

在【理货单】界面,点击【打印工单标签】,核对打印工单范围,点击【打印】即可。打印出来的“理货标签”用于RF终端理货任务的领用,理货工单创建完成。(图2.3.5、图2.3.6)

③ Print tally work order labels

On the [Tally Sheet] interface, click [Print Ticket Label], check the range of printed work orders, and click [Print]. The printed "tally label" is used for the RF terminal tally task, and the tally work order is created. (Figure 2.3.5, Figure 2.3.6)

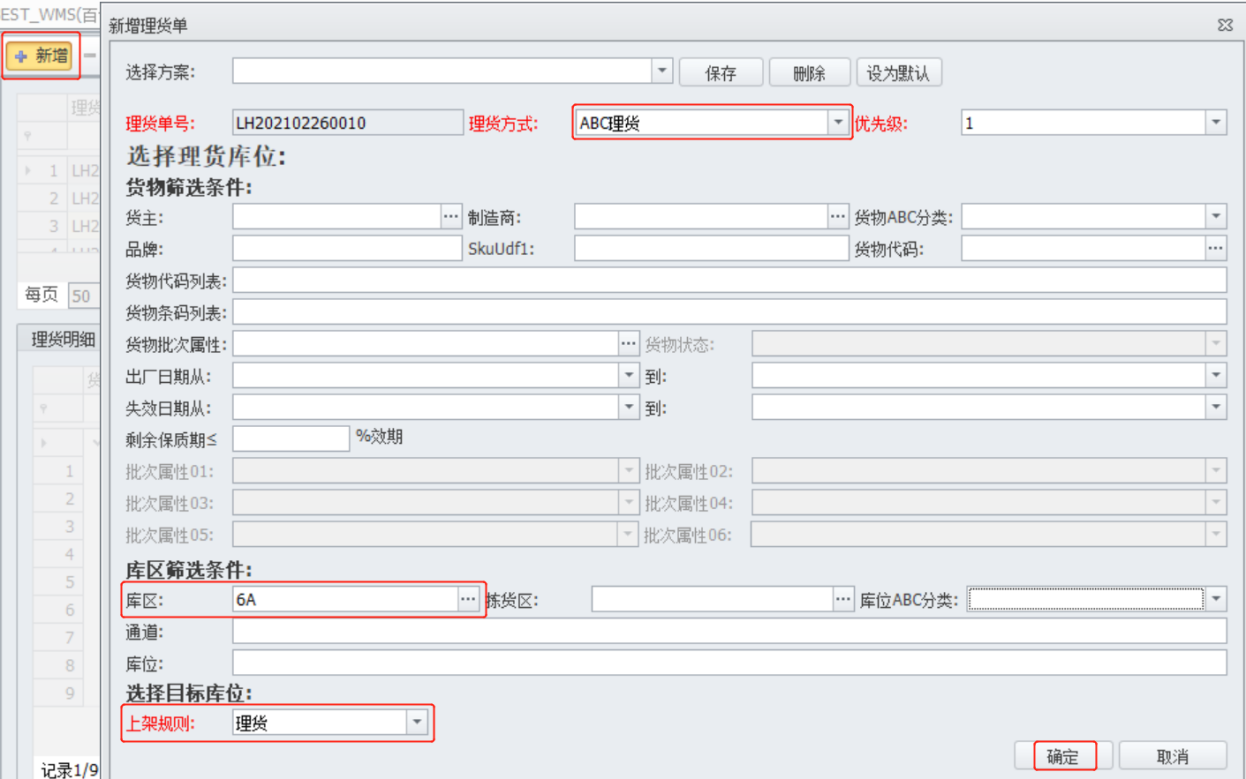

ABC理货的任务创建

① 创建理货单

系统组员在电脑【WMS】的菜单栏中选择【理货单】,点击【新增】,在【新增理货单】界面,【理货方式】处选择【ABC理货】,在【库区】处选择需要理货的库区范围,点击【确定】,此时系统根据货物的当前ABC类别重新分配库位。(图2.3.7)

ABC tally task creation

① Create a tally list

The system team members select [Tally List] in the menu bar of the computer [WMS], click [Add], select [ABC Tallying] in the [New Tally List] interface, select [Tally Method] at [Tally Method], select the range of the storage area that needs to be tally at [Storage Area], click [OK], and the system will reallocate the inventory location according to the current ABC category of the goods. (Figure 2.3.7)

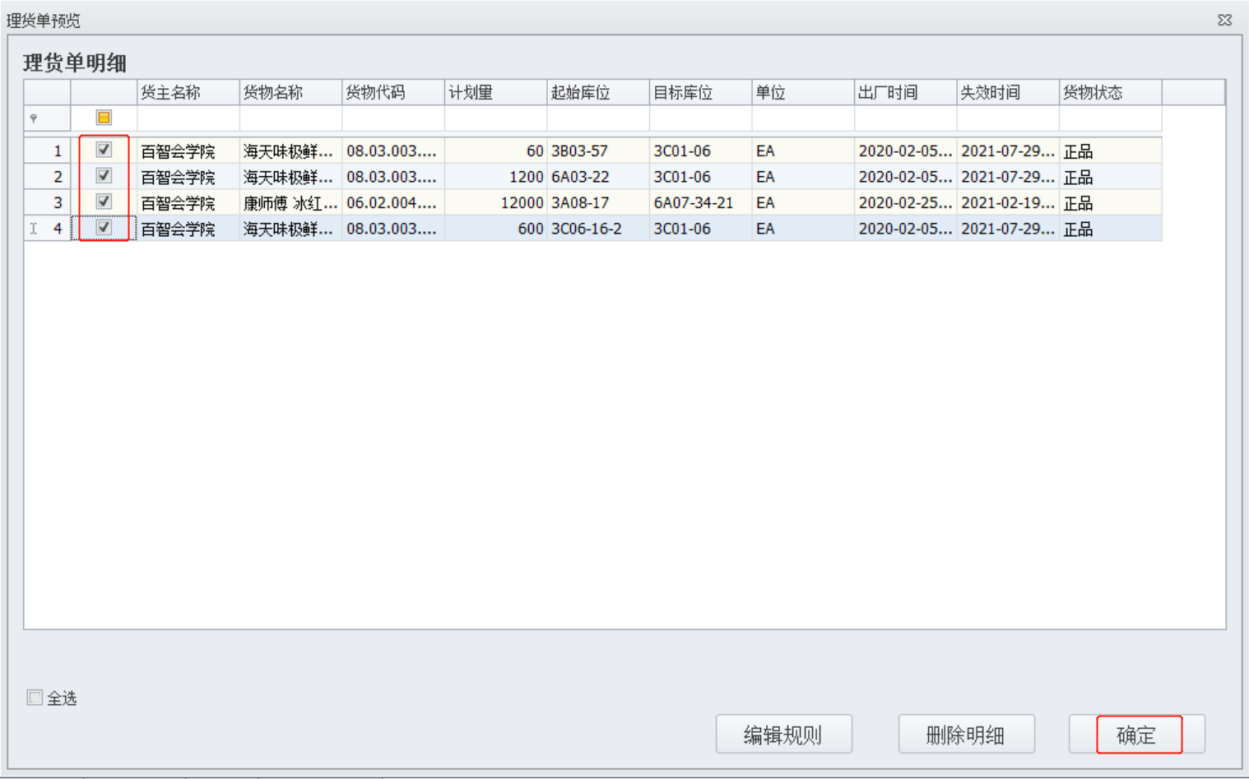

分配完成后,在【理货单预览】界面选择全部理货单明细,点击【确定】,生成理货单。(图2.3.8)

After the assignment is completed, select all the tally details on the [Tally List Preview] interface, and click [OK] to generate a tally list. (Figure 2.3.8)

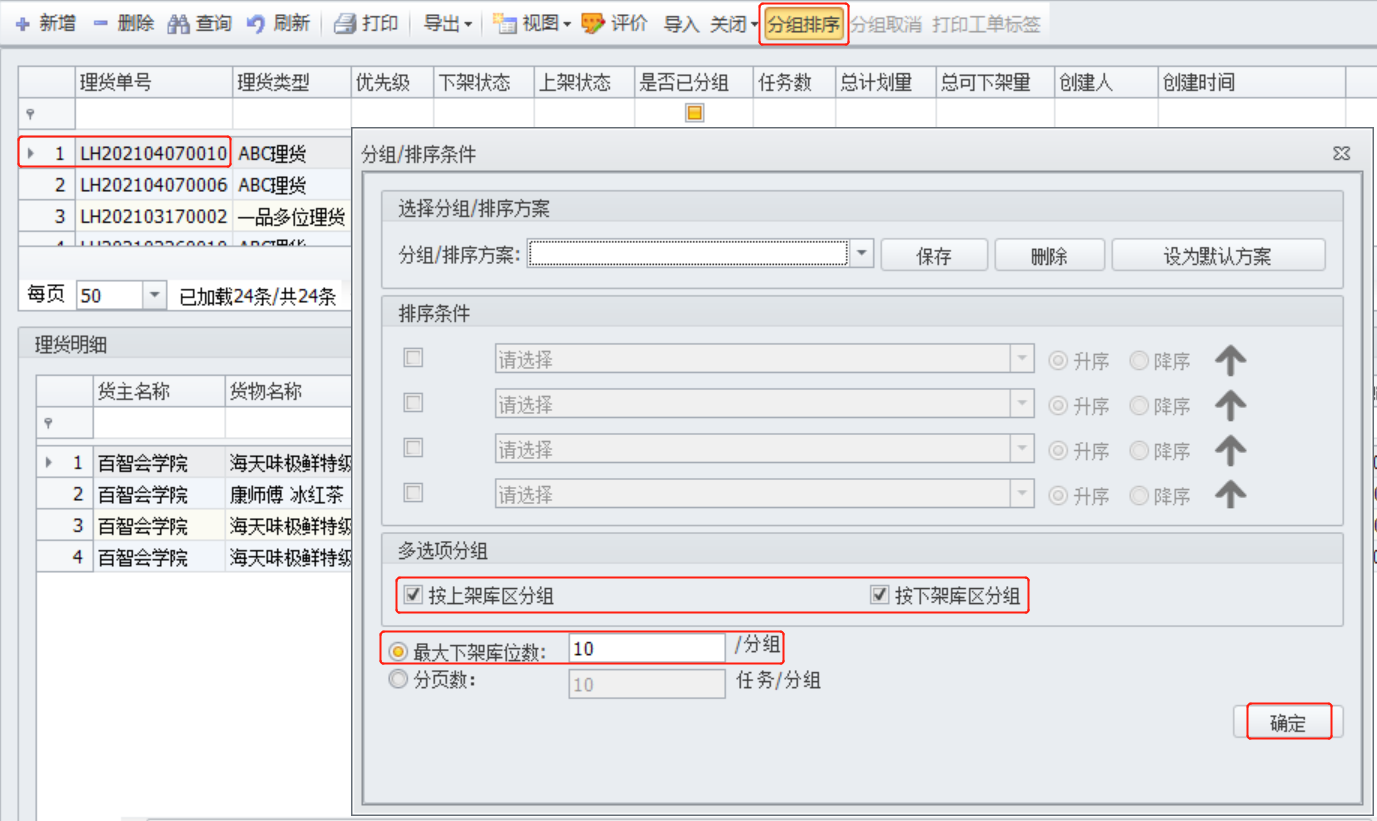

② 创建理货工单

在【理货单】界面选中生成的理货单,点击【分组排序】,配置分组条件,点击【确定】,生成理货工单。(图2.3.9)

② Create a tally work order

In the [Tally List] interface, select the generated tally sheet, click [Group Sorting], configure the grouping conditions, and click [OK] to generate the tally work order. (Figure 2.3.9)

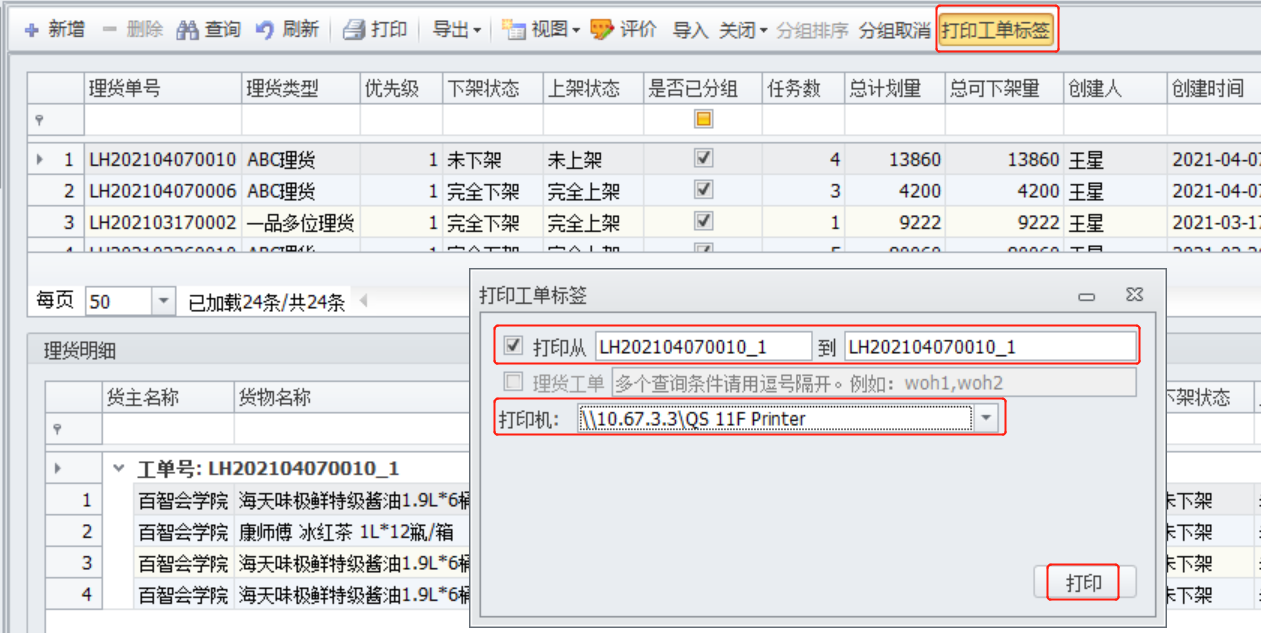

③ 在【理货单】界面,点击【打印工单标签】,核对打印工单范围,理货工单创建完成。(图2.3.10、图2.3.11)

③ On the [Tally List] interface, click [Print Work Order Label] to check the scope of the printed work order, and the tally work order is created. (Figure 2.3.10, Figure 2.3.11)

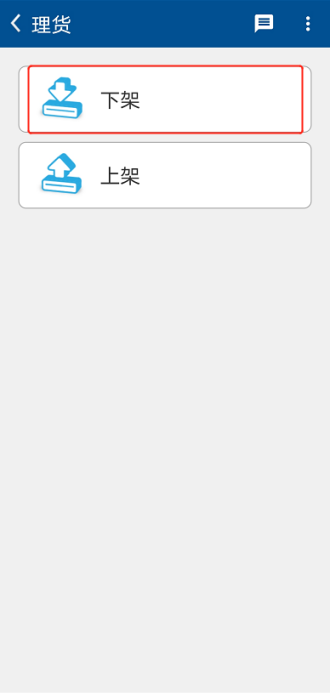

任务领用

库存组长组织库存组员开始理货。库存组长逐一发放“理货工单标签”,库存组员首先在RF终端上领取理货任务。

在RF终端【WMS】首页选择【理货】,点击【下架】,在【获取工单】界面【工单号】处扫描“理货工单标签”上的条码,系统会显示该工单对应的待下架货物信息及下架库位。(图2.3.12、图2.3.13、图2.3.14)

Task requisition

The inventory team leader organizes the inventory team members to start tallying. The inventory team leader issues the "tally work order label" one by one, and the inventory team member first receives the tally task on the RF terminal.

Select [Tallying] on the Home of RF terminal [WMS], click [Remove Listing], scan the barcode on the "Tally Work Order Label" at [Work Order Number] on the [Get Work Order] interface, and the system will display the information of the goods to be removed and the location corresponding to the work order. (Figure 2.3.12, Figure 2.3.13, Figure 2.3.14)

作业开始

理货下架

库存组员获取理货下架工单后,开始理货作业,并将货物下架。

首先,在RF终端【WMS】的【获取工单】界面,点击首行明细,在【开始下架】界面【到LPN】处扫描LPN条码,点击【确认】。(图2.3.15、图2.3.16)

Start of operation

Tally and off-shelving

After the inventory team member obtains the tally and off-shelving work order, they start the tally operation and remove the goods from the shelves.

First of all, on the [Get Work Order] page of the RF terminal [WMS], click the first line of details, scan the LPN barcode at [Go to LPN] on the [Start Removal] interface, and click [Confirm]. (Figure 2.3.15, Figure 2.3.16)

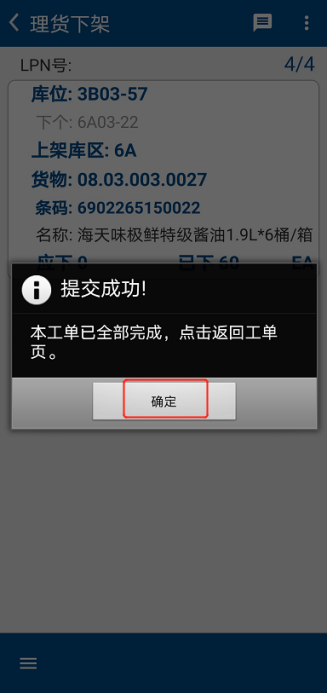

然后,在【理货下架】界面【库位】处扫描库位条码,在【货物】处扫描货品条码,核对下架库位上的实物名称和数量,如果当前箱子已经装满则点击【换下一箱F1】,系统显示【换下一箱,当前条已做完】,弹出扫描新的理货框LPN码。(图2.3.17、图2.3.18)

重复以上步骤,直至工单所有库位下架完成后,系统提示【提交成功】,点击【确定】,并将“理货标签”贴在货物显眼位置。(图2.3.19)

Then, scan the barcode of the bin location at the [Inventory Location] of the [Tally Off the Shelf] interface, scan the barcode of the goods at the [goods], check the physical name and quantity of the bin location off the shelf, if the current box is full, click [Replace the Next Box F1], the system will display [Replace the Next Box, the Current bar has been completed.], and pop up to scan the new tally box LPN code. (Figure 2.3.17, Figure 2.3.18)

Repeat the above steps until all locations of the work order are removed from the shelves, the system prompts [Submitted successfully], clicks [OK], and pastes the "Tally Label" in a conspicuous position of the goods. (Figure 2.3.19)

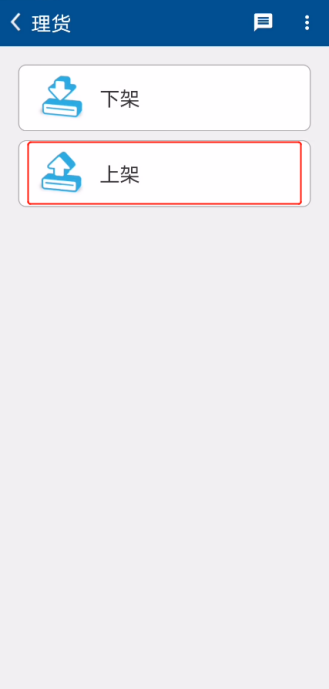

理货上架

完成下架后,库存组员再获取上架工单,将货物上架。

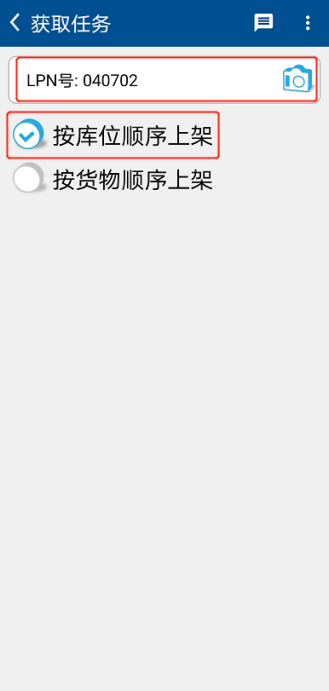

① 在RF终端【WMS】首页选择【理货】。点击【上架】,在【获取任务】界面勾选【按库位顺序上架】,在【LPN号】处扫描待上架货物上的LPN条码。系统跳转至【按库位顺序上架】界面,显示待上架货物信息及目标库位。(图2.3.20、图2.3.21、图2.3.22)

Tally on the shelves

After the removal is completed, the inventory team member obtains the shelf work order and puts the goods on the shelf.

① Select [Tally] on the Home of the RF terminal [WMS]. Click [Shelving], select [Shelving by Inventory Location] on the [Get Task] interface, and scan the LPN barcode on the goods to be put on the shelf at [LPN Number]. The system jumps to the [Put on the shelves in order by location] interface, and displays the information of the goods to be put on the shelves and the target location. (Figure 2.3.20, Figure 2.3.21, Figure 2.3.22)

②点击上架任务明细首行,进入【按库位顺序上架】详情界面,在【库位】处扫描库位条码,在【货物】处扫描货物条码,在【数量】处输入上架货物数量,核对无误后,点击【确认F2】,系统提示【提交成功】。将上架货物转移至上架库位,以托盘为单位上架的,撕掉LPN条码。

②Click on the first line of the shelving task details to enter the details interface of [Shelving in Order of Inventory Location], scan the barcode of the storage location at [Storage Location], scan the barcode of the goods at [Goods], enter the quantity of goods on the shelves at [Quantity], and after checking that it is correct, click [Confirm F2], and the system prompts [Submitted successfully]. Transfer the goods on the shelves to the storage location on the shelves, and tear off the LPN barcode if they are put on the shelves in pallets.

重复以上步骤,直至领取工单的所有货物上架完成后,系统提示【提交成功】,点击【确定】。(图2.3.23)

作业完成

库存组长检查理货进度,确保当天所有人员理货完成。

Operation completion

The inventory team leader checks the progress of tally to ensure that all personnel complete the tally on the same day.

专业核心词汇 Vocabulary

理货 tally

一品多位理货 one SKU multiple locations

ABC理货 ABC tally

上架 shelving

下架 off-shelving

库位 bin location

学习拓展 Further Reading

理货作业操作要点

1.现场库区库位较多时,需要先按库区生成理货工单,降低每个理货工单上的任务数量。

2.货物按照ABC分类,需要与库位ABC分类对应,通过理货功能转移货物的库位,完成货物与库位的ABC分类对应。

3.理货作业中,工单中的货物如未理货完成,则无法分配出库订单,因此,需要快速处理,否则会影响出库作业。

Key Points of Tally Operation

1.When there are many inventory locations in the on-site storage area, it is necessary to generate a tally work order according to the storage area to reduce the number of tasks on each tally work order.

2.The goods are classified according to ABC, which needs to correspond to the ABC classification of the storage location, and the storage location of the goods is transferred through the tally function to complete the ABC classification correspondence between the goods and the storage location.

3.In the tally operation, if the goods in the work order are not tally completed, the outbound order cannot be assigned, so it needs to be processed quickly, otherwise the outbound operation will be affected.

知识巩固 Consolidation

排序题

以下词条为理货作业具体步骤,如选择任务创建为第一步,则用数字标明①,后续步骤请按照作业顺序依次进行编号。

任务创建(①)

理货下架( )

理货上架( )

作业完成( )

任务领用( )

答案:①③④⑤②选择题

1.一个货品在多个库位存放,且都未放满时,通过( )来进行存放库位的合并。

A.盘点

B.理货

C.补货

D.移库

答案:B2.理货作业时要( )。

A.先进行下架操作

B.先进行上架操作

C.下架和上架操作可以交替进行

D.下架和上架操作可以合并进行

答案:A3.理货是为了提高仓储库位利用率而进行的一项日常作业。【WMS】支持( )。

A.一品多位理货

B.一位多品理货

C.ABC理货

D.定期理货

答案:AC判断题

1.一品多位理货是指货品按照ABC分类,需要与库位ABC分类对应,通过转移货品的库位来进行货品与库位的ABC分类对应。( )

答案:×2.在理货上架操作时可以选择按库位顺序上架,也可以选择按货位顺序上架。( )

答案:×技能训练

训练任务 实施理货作业

【训练目标】

1.熟悉一品多位理货和ABC理货作业流程。

2.能够在仓储管理系统(WMS)中创建理货工单。

3.熟练运用RF 终端按照标准作业流程实施一品多位理货和ABC理货。

【训练内容】

结合学校实训室或合作企业仓库,选择12个库区,分别完成一品多位理货和ABC理货。

【训练步骤】

小组分配岗位,明确第一库区(设为1A)理货人员和第二库区(设为1B)理货人员,然后进行下列操作:

1.请对第一库区(1A)存放库位数量2的货物创建一品多位理货单。

2.请对第二库区(1B)进行ABC理货的任务创建。

3.配置分组条件,创建理货工单,并打印【理货工单标签】。

4.库存组员使用RF终端领取理货任务。

5.分别实施一品多位理货和ABC理货作业。

6.理货作业完成后,库存组长检查并反馈至系统组员。

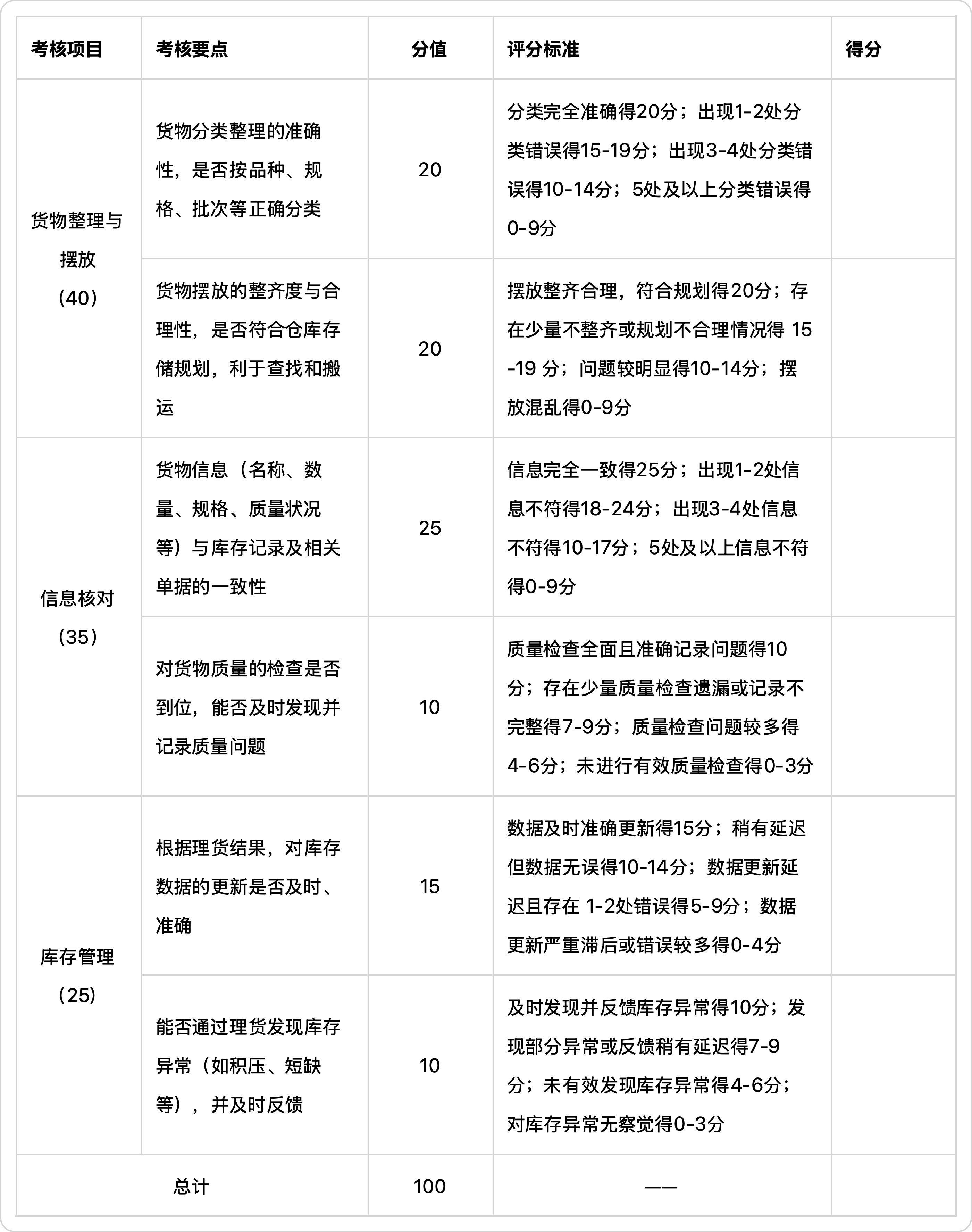

【考核评价】

微课

理货作业规则及工单创建

工作视频

理货作业-1工具准备

理货作业-2系统操作

课件

任务小结

本节课学习任务要点梳理如2.3.5表所示: