任务1 堆码作业

Task One Stacking Operation

任务导入 Lead-in

库存组张组长:小方,今天有一批五金件需要入库,通知相应人员待收货组完成入库后进行货物堆码。

库存组员方新:组长,这批五金件具体是什么样的包装

库存组张组长:是箱装五金件,你准备选择哪种堆码方法

库存组员方新:组长,箱装五金件我考虑采用垛堆法。

库存组张组长:好的,一定要进行合理设计,充分利用仓容,做到仓库内整齐,方便作业和保管。

库存组员方新:好的组长,我会做好垛基垛形货垛堆码标准的设计和确定。

库存组张组长:堆垛时注意货垛不要倚墙靠柱,垛间不要挤压得太紧。

库存组员方新:组长,我会严格按照五距要求进行堆码,请放心。

Leader Zhang of Inventory Team: Xiaofang, there is a batch of metals that needs to be put into storage today, and the corresponding personnel will be notified to stack the goods after the receiving group completes the warehousing.

Member Fang Xin of Inventory Team: Mr. Zhang, what kind of packaging is this batch of hardware?

Leader Zhang of Inventory Team: It is boxed metals, which stacking method are you going to choose?

Member Fang Xin of Inventory Team: Mr. Zhang, I consider using the stacking method for boxed metals.

Leader Zhang of Inventory Team: Okay, we must design it properly, make full use of the warehouse capacity, so that the warehouse is neat, convenient for operation and storage.

Member Fang Xin of Inventory Team: Okay Mr. Zhang, I will make sure of it in the design and determination of the stacking base, stacking shape, and stacking standards.

Leader Zhang of Inventory Team: When stacking, pay attention to the stacks. Do not lean against the wall and lean against the column, and do not squeeze too tightly between the stacks.

Member Fang Xin of Inventory Team: Mr. Zhang, I will stack in strict accordance with the requirements of the five distances, please rest assured.

物品堆码的基本方法 The Basic Method For Stacking Items

仓库应根据物品的特性、包装方式和形状、保管的需要,确保物品质量、方便作业和充分利用仓容,以及根据仓库的条件确定物品堆码的基本方法。物品堆码的基本方法有以下几种:

散堆法

散堆法适用于露天存放的没有包装的大宗货物,如煤炭、矿石、黄沙等,也可适用于库内的少量存放的谷物、碎料等散装货物。散堆法是直接用堆扬机或者铲车在确定的货位后端起,直接将货物堆高,在达到预定的货垛高度时,逐步后退堆货,后端先形成立体梯形,最后成垛,整个垛形呈立体梯形状。

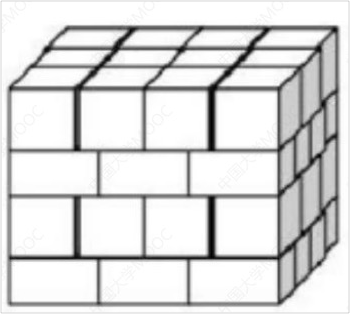

货架存放

适用于小件、品种规格复杂且数量较少,包装简易或脆弱、易损害不便堆垛的货物,特别是价值较高而需要经常查数的货物仓储存放。货架存放需要使用专用的货架设备。

垛堆法

对于有包装(如箱、桶、袋、箩筐、捆、扎等包装)的货物,包括裸装的计件货物,采取堆垛的方式储存。堆垛之前应进行合理设计,才能充分利用仓容,做到仓库内整齐,方便作业和保管。

The warehouse should ensure the quality of the goods, facilitate the operation and make full use of the warehouse capacity according to the characteristics of the goods, the packaging method and shape, and the needs of storage, as well as determine the basic method for stacking the goods according to the conditions of the warehouse. There are several basic ways to stack items:

Scattering method

The bulk stacking method is suitable for unpackaged bulk goods stored in the open air, such as coal, ore, yellow sand, etc., and can also be applied to bulk goods such as grains and scraps stored in a small amount in the warehouse. The bulk stacking method is to directly use a stacker or forklift to start at the back end of the determined goods location, directly stack the goods high, and gradually retreat to pile the goods when reaching the predetermined stacking height. The rear end first forms a three-dimensional trapezoid, and finally becomes a stack, and the whole stack is in the shape of a three-dimensional ladder.

Shelf storage

It is suitable for small pieces, complex varieties and specifications, small quantities, simple or fragile packaging, easy to be damaged and inconvenient stacking of goods, especially for the storage and storage of goods with high value and need to be checked frequently. Shelving requires the use of specialized shelving equipment.

Stacking method

For packaged goods (such as boxes, barrels, bags, baskets, bundles, ties, etc.), including naked piece-rate goods, they are stored in a stacked manner. Proper design should be carried out before stacking, so as to make full use of the warehouse capacity, so that the warehouse is neat, convenient for operation and storage.

货垛的堆码方式有以下8种:

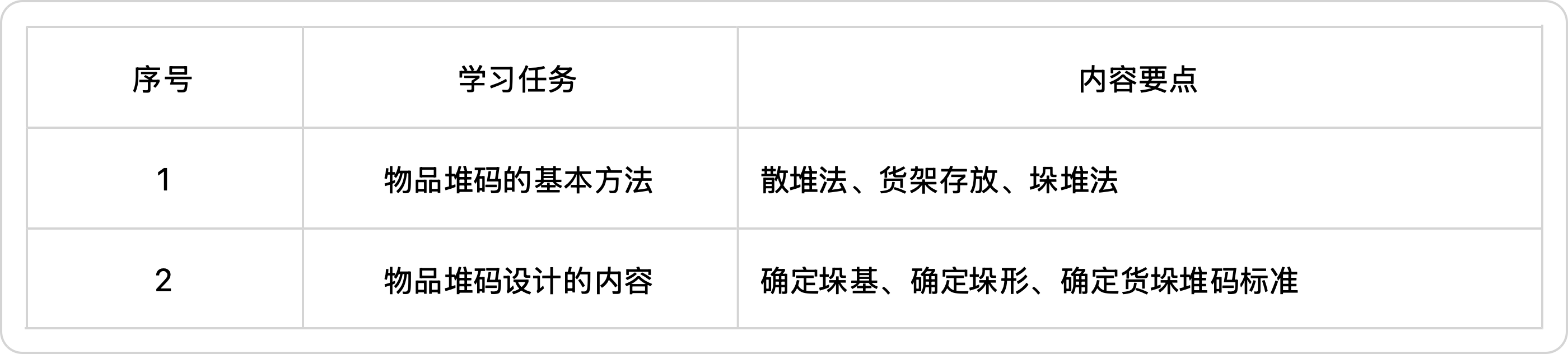

重叠式。重叠式也称直堆法,逐件、逐层向上重叠堆码,一件压一件的堆码方式。该方法较方便作业、计数,但稳定性较差。适用于袋装货物、箱装、箩筐装货物,以及平板、片式货物等。(图2.1.1)

There are 8 ways to stack:

Overlapping. The overlapping type is also known as the straight stacking method, which stacks up one piece by one and layer by layer, and presses one piece by one. This method is more convenient for operation and counting, but the stability is poor. It is suitable for bagged goods, boxed goods, basket goods, as well as flat and sheet goods. (Figure 2.1.1)

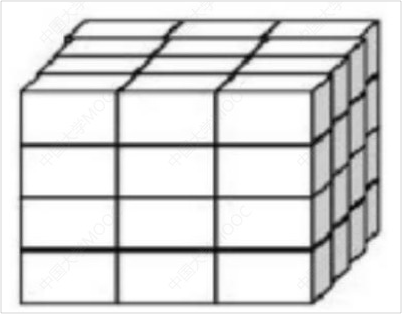

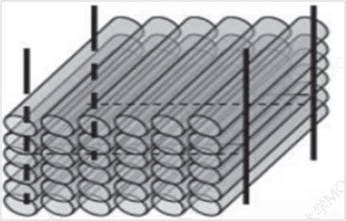

纵横交错式。每层货物都改变方向向上堆放。适用于管材、捆装、长箱装货物等货物。该方法较为稳定,但操作不便。(图2.1.2)

Criss-cross. Each layer of goods is stacked upwards in a different direction. It is suitable for pipes, bundles, long boxes and other goods. This method is relatively stable, but it is inconvenient to operate.

仰俯相间式。对上下两面有大小差别或凹凸的货物,如槽钢、钢轨、箩筐等,将货物仰放一层,再反一面俯放一层,仰俯相间相扣。该垛极为稳定,但操作不便。(图2.1.3)

Up and down alternating. For the goods with size difference or concave and convex on the upper and lower sides, such as channel steel, steel rails, baskets, etc., put the goods on the back of a layer, and then on the reverse side of the bottom of the skin, and the elevation is interlocked. The stack is extremely stable, but it is difficult to operate. (Figure 2.1.3)

压缝式。将底层并排摆放,上层放在下层的两件货物之间。如果每层货物都不改变方向,则形成梯形形状;如果每层都改变方向,则类似于纵横交错式。上下层件数的关系分为“2顶1”、“3顶2”、“4顶1”、“5顶3”等。(图2.1.4)

Pressing seam. Place the ground floor side by side, with the upper layer placed between the two pieces of goods on the lower floor. If each layer of goods does not change direction, a trapezoidal shape is formed; If each layer changes direction, it resembles a criss-cross pose. The relationship between the number of pieces in the upper and lower layers is divided into "2 against 1", "3 against 2", "4 against 1", "5 against 3", etc . (Figure 2.1.4)

栽柱式。码放货物前在货垛两侧栽上木桩或者钢棒(如U形货架),然后将货物平码在桩柱之间,几层后用铁丝将相对两边的柱拴联,再往上摆放货物。此法适用于棒材、管材等长条状货物。(图2.1.5)

Pillar planting. Before stacking the goods, plant wooden piles or steel rods on both sides of the stack (such as U-shaped shelves), and then stack the goods flat between the piles, and then tie the columns on both sides with iron wires after several layers, and then place the goods on them. This method is suitable for long strip goods such as bars and pipes. (Figure 2.1.5)

衬垫式。码垛时,隔层或隔几层铺放衬垫物,衬垫物平整牢靠后,再往上码。适用于不规则且较重的货物,如无包装电机、水泵等。(图2.1.6)

Cushioning. When stacking, the cushion is laid in the compartment or several layers, and the cushion is flat and firm, and then stacked up. It is suitable for irregular and heavier goods, such as unpackaged motors, water pumps, etc. (Figure 2.1.6)

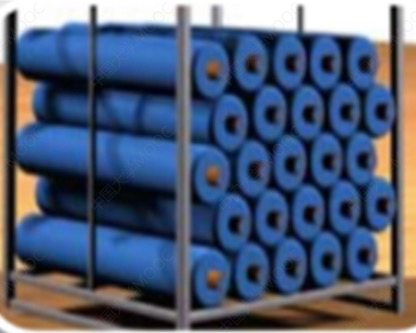

直立式。货物保持垂直方向码放的方法。适用于不能侧压的货物,如玻璃、油毡、油桶、塑料桶等。

Upright. The method of keeping the goods stacked in the vertical direction. It is suitable for goods that cannot be pressed on the side, such as glass, linoleum, oil drums, plastic drums, etc.

“五五化”堆垛。“五五化”堆垛就是以五为基本计算单位,堆码成各种总数为五的倍数的货垛,以五或五的倍数在固定区域内堆放,使货物"五五成行、五五成方、五五成包、五五成堆、五五成层",堆放整齐,上下垂直,过目知数。便于货物的数量控制、清点盘存。(图2.1.7)

"Five-five" stacking. "Five-five" stacking is to take five as the basic unit of calculation, stacked into a variety of total of five multiples of the stack, with five or five's multiples stacked in a fixed area, so that the goods "five five into a row, five into a square, five into a package, five into a pile, five into a layer", stacked neatly, up and down vertically, through the eyes to know the number. It is convenient for quantity control and inventory of goods (Figure 2.1.7).

物品堆码设计的内容 The Content of the Item Stacking Design

为了符合物品堆码的基本原则与要求,仓库必须根据保管场所的实际情况、物品本身的特点、装卸搬运条件和技术作业过程的要求,对物品堆码进行设计。物品堆码设计的内容包括确定垛基、确定垛形、确定货垛堆码标准。

确定垛基

垛基是货垛的基础,其主要作用:随整个货垛的重量,将物品的垂直压力传递给地坪;将物品与地面隔离,起防水、防潮和通风的作用;垛基空间为搬运作业提供了方便。

确定垛形

垛形是指货琛的外部形状。按垛底的平面形状,可将垛形分为矩形、正方形、三角形、圆形、环形等;按货垛立面的形状,可将垛形分为矩形、正方形、三角形、梯形、半圆形;另外,还包括矩形-三角形、矩形-梯形、矩形-半圆形等复合形状。各种不同形状的货垛都有各自的特点。矩形垛、正方形垛易于堆码,便于盘点计数,仓库整齐,但随着堆码高度的增加,货垛的稳定性会下降;梯形垛、三角形垛和半圆形垛的稳定性好,便于苦盖,但是不便于盘点计数,也不利于仓容的利用:矩形-三角形等复合形状的货垛恰好可以整合它们的优点,尤其适用于物品在露天存放的情况。

垛形的确定要依据物品的特性和保管的需要,并遵循使实际作业方便、迅速和充分利用仓容的原则。

In order to meet the basic principles and requirements of item stacking, the item stacking in the warehouse must be designed properly according to the actual situation of the storage place, the characteristics of the item itself, the loading and unloading conditions and the requirements of the technical operation process. The content of the article stacking design includes determining the stacking base, determining the stacking shape, and determining the stacking standard.

Determine the base of the stack

The base of the stack is the basis of the stack, and its main functions are: with the weight of the entire stack, the vertical pressure of the item is transmitted to the floor; Isolate items from the ground to prevent water, moisture and ventilation; The stacking space provides convenience for handling operations.

Determine the stack shape

The buttress refers to the external shape of the goods. According to the plane shape of the bottom of the stack, the stack can be divided into rectangle, square, triangle, circle, ring, etc.; According to the shape of the stack façade, the stack can be divided into rectangle, square, triangle, trapezoidal and semicircular; In addition, compound shapes such as rectangle-triangle, rectangle-trapezoidal, rectangle-semicircle are also included. The various stacks of different shapes have their own characteristics. Rectangular stacks and square stacks are easy to stack, which is convenient for inventory and counting, and the warehouse is neat, but with the increase of stacking height, the stability of the stack will decrease; The stability of trapezoidal stacks, triangular stacks and semicircular stacks is good, which is convenient for bitter cover, but it is not convenient for inventory counting, and it is not conducive to the utilization of warehouse capacity: rectangular-triangular and other composite shape stacks can just integrate their advantages, especially suitable for the situation that the items are stored in the open air.

The determination of the stacking shape should be based on the characteristics of the goods and the needs of storage, and follow the principle of making the actual operation convenient, rapid and full use of the warehouse capacity.

确定货垛堆码标准

垛高

垛高会直接影响仓库的容量、安全和货垛的稳定性,所以在确定垛高时要综合考虑库地坪允许垛高、物品包装允许垛高、仓库空间允许垛高这3项指标,选用3个指标中的最小值,才能在保证仓库地坪安全及物品本身不被损坏的前提下实现仓容利用的最大化。

货垛的"五距"是指墙距、柱距、顶距、垛距和灯距,即货垛不能倚墙靠柱,垛间不能挤压得太紧,货垛不能与屋顶和照明设备相连、无间距。

墙距,分为外墙距和内墙距。外墙距是指货垛与外墙间的必要距离,一般保留0.5m的间距;内墙距是指货垛与内墙间的必要距离,一般保持0.3m的间距,主要防止墙壁的潮气对货物的影响,便于开关库窗、检点货物、通风散潮等。

柱距,是指货垛与库房立柱间保留的必要距离,一般为0.2m,主要是防止立柱潮气影响货物并保护建筑物安全。

顶距,是指货垛顶部与库房顶部最低建筑构造物之间保留的必要距离。一般平房仓库顶距为0.3m,多层建筑库房顶层的顶距不得低于0.5m。

垛距,是指货垛间的必要距离,主要起通风、散热和方便进出等作用,仓库内的垛距应不小于0.5m。

灯距,是指货垛顶部与照明灯之间的必要距离,主要起防止火灾的作用灯距严格规定不得小于0.5m。

Determine the stacking standard

Stack height

Stacking height will directly affect the capacity, safety and stability of the warehouse, so when determining the stacking height, it is necessary to comprehensively consider the three indicators of the allowable stacking height of the warehouse floor, the allowable stacking height of the goods packaging, and the allowable stacking height of the warehouse space, and select the minimum value of the three indicators, so as to maximize the utilization of warehouse capacity under the premise of ensuring the safety of the warehouse floor and the goods themselves are not damaged.

The "five distances" of the stack refer to the distance from the wall, from the column, from the top, from the stack and from the lamp, that is, the stack can not lean against the wall and the column, the stack can not be squeezed too tightly, and the stack can not be connected with the roof and lighting equipment, without spacing.

Wall spacing, divided into exterior wall spacing and inner wall spacing. The distance between the outer wall refers to the necessary distance between the stack and the outer wall, and the spacing of 0.5m is generally retained; the distance between the inner wall refers to the necessary distance between the stack and the inner wall, and the spacing of 0.3m is generally maintained, which mainly prevents the influence of moisture of the wall on the goods , and is convenient for opening and closing the warehouse window, inspecting the goods, ventilating and dispersing the moisture, etc.

Distance from the column refers to the necessary distance between the pallet and the warehouse column, generally 0.2m, mainly to prevent the column moisture from affecting the goods and protect the safety of the building.

Distance from the top refers to the necessary distance between the top of the stack and the minimum building structure at the top of the warehouse. Generally, the top distance of the bungalow warehouse is 0.3m, and the top distance of the top floor of the multi-storey building warehouse shall not be less than 0.5m.

Distance from the stack refers to the necessary distance between the stacks, mainly for ventilation, heat dissipation and convenient access and other functions, the stacking distance in the warehouse should not be less than 0.5m.

Distance from the lamp refers to the necessary distance between the top of the stack and the lamp, which mainly plays the role of preventing fire, and the lamp distance is strictly stipulated to be not less than 0.5m.

专业核心词汇 Vocabulary

堆码 stacking

散堆 scattered stacking

货架 shelf

垛堆 regular stacking

垛基 stacking bases

垛形 stacking shape

垛高 stacking height

墙距 distance from the wall

柱距 distance from the column

顶距 distance from the column

垛距 distance from the stack

灯距 distance from the lamp

学习拓展 Further Reading

堆码的基本原则

1.分类存放原则

分类存放是仓库保管的基本要求,是保证货物质量的重要手段。分类存放包括:不同类别的货物分类存放,甚至需要分库存放;不同规格、不同批次的货物分位、分堆存放;残损货物要与原货分开,放在原货堆边上;不同流向、不同经营方式的货物也要分类存放;对需要分拣的货物,在分拣之后应分位存放,以免再次混合。

2.摆放整齐、适当搬运活性原则

为了减少作业时间和作业次数,提高仓库周转速度,应根据货物作业的要求,合理选择货物的搬运活性。对搬运活性高的货物,也应注意摆放整齐,以免堵塞通道,浪费仓容。

3.垛形稳固、垛高适当原则

为了充分利用仓容,存放的货物要尽可能码高,使货物占用地面面积最小,但不能超过仓库地面承载力和货物本身堆高限定,因此垛高要适当。货物堆垛必须稳固,避免倒垛、散垛,要求叠垛整齐、放位准确,必要时采用稳固方法,如垛边、垛头采用纵横交叉叠垛,使用固定物料加固等。只有在货垛稳固的情况下才能码高。

4.面向通道、不围不堵原则

面向通道包括两方面意思:一是码垛存放的货物的正面尽可能面向通道,以便察看。货物的正面是指标注主标志的一面。二是所有货物的货垛、货位都有一面与通道相连,处在通道旁,以便能对货物进行直接作业。只有在所有货位都与通道相通时,才能保证不围不堵。

The Basic Principles of Stacking

1.Principle of classified storage

Classified storage is the basic requirement of warehouse storage and an important means to ensure the quality of goods. Classified storage includes: classified storage of different types of goods, and even needs to be stored separately; Separate and stacked storage of goods of different specifications and batches; The damaged goods should be separated from the original goods and placed on the edge of the original goods pile; Goods with different flows and different modes of operation should also be stored separately; For the goods that need to be sorted, they should be stored separately after sorting to avoid remixing.

2.The principle of neat placement and proper handling of goods

In order to reduce the operation time and the number of operations, and improve the turnover speed of the warehouse, the handling of the goods should be reasonably selected according to the requirements of the goods operation. For the goods with high handling frequency, attention should also be paid to neatly placing them, so as not to block the passage and waste the warehouse capacity.

3.The principle of stable stacking shape and appropriate stacking height

In order to make full use of the warehouse capacity, the stored goods should be as high as possible, so that the goods occupy the smallest ground area, but can not exceed the warehouse ground bearing capacity and the height limit of the goods themselves, so the stack height should be appropriate. The stacking of goods must be stable, avoid stacking and scattering. Neat stacking and accurate placement are required, and stable methods should be adopted if necessary, such as stacking edges and stacking heads using vertical and horizontal cross stacking, and using fixed materials to reinforce. Yard height can only be achieved if the stack is stable.

4.The principle of facing the channel, no encirclement and no blockage

Facing the channel includes two meanings: one is that the front of the palletized and stored goods is as far as possible facing the channel for easy inspection. The front of the goods refers to the side marked with the main mark. Second, the stacks and goods locations of all goods are connected to the channel on one side and are located next to the channel, so that the goods can be directly operated. Only when all goods locations are connected to the channel can it be guaranteed that there is no encirclement or blockage.

知识巩固 Consolidation

认知题

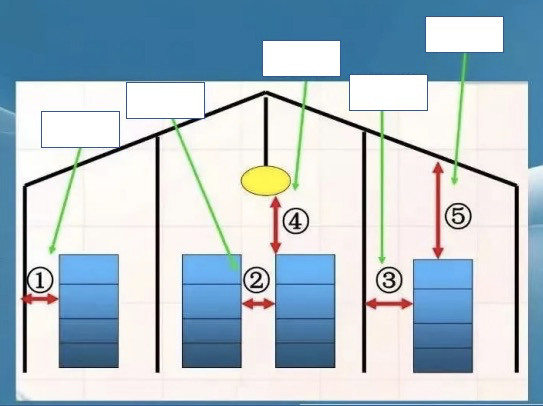

看图片,选择对应的堆码方式进行连线。

A.重叠式

B.纵横交错式

C.栽柱式

答案:①C ②B ③A选择题

请根据所学知识,选择图片中对应的五距。

A.墙距

B.柱距

C.顶距

D.垛距

E.灯距

答案: ①A ②D ③B ④E ⑤C技能训练

训练任务 实施堆码作业

【训练目标】

能根据不同货物选择合理的堆码方法,并能熟练进行堆码作业。

【训练内容】

利用叉车进行箱装五金货物的堆码操作。

【训练步骤】

1.准备卷尺、货架、托盘、叉车、帆布、绳索、辅料等。

2.计算货物要码放的层数。

3.将五金货物箱平行排列。

4.堆码过程中按先远后近的原则进行。

5.将底层的五金货物堆码整齐,箱与箱之间不留空隙。

6.箱与箱的交接应为正面与正面衔接,侧面与侧面衔接。

7.将五金货物逐层堆码,层与层之间的货物箱平行,货物箱的四个角边重叠,方向相同,直到堆码完成。

8.堆码审核。检查是否有变形的、超过堆码层数极限的或包装颠倒的包装箱等。

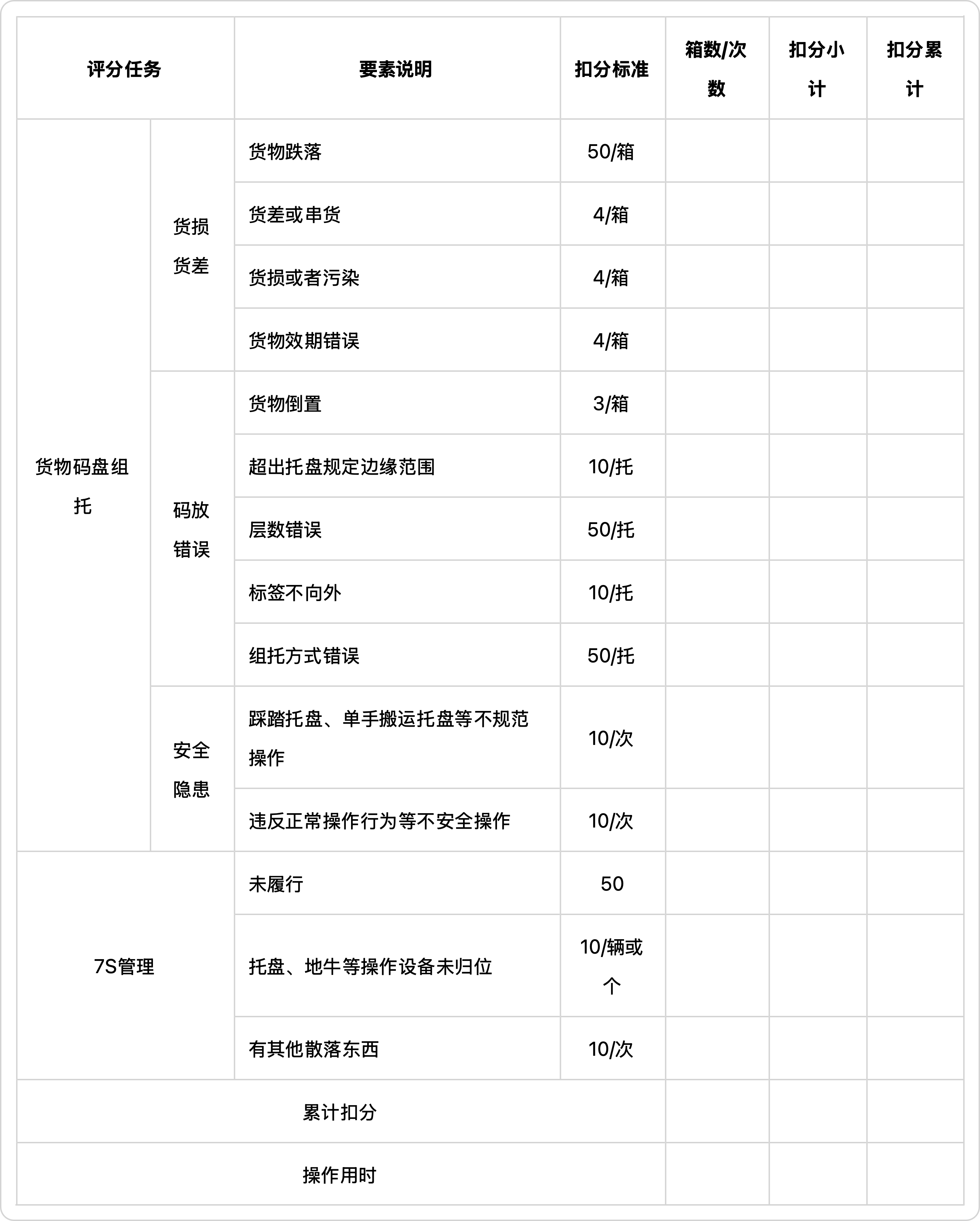

【考核评价】

微课

托盘堆码

课件

任务小结

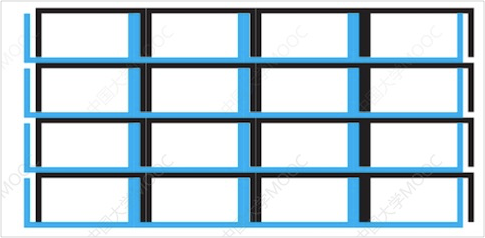

本节课学习任务要点梳理如表2.1.2所示: