任务2 采购收货作业

Task Two Purchasing and Receiving Operations

任务导入 Lead-in

收货组张组长:李亮,按照预约时间,今天上午8点有一批货物抵达仓库,请你与司机做好对接工作,做好送货人员登记表。

收货组员李亮:好的,张组长,我会根据预约登记表再次确认相关信息。

收货组张组长:另外我前几天巡查仓库,发现有的货品码放不标准,已让相关人员重新码放这次收货作业一定要严格按照工作标准和规范要求实施。

收货组员李亮:好的,张组长,这次一定会参照标准作业流程敦促工作人员做好收货作业。

Leader Zhang of Receiving Team: Li Liang, according to the scheduled time, a batch of goods will arrive at the warehouse at 8 o'clock this morning. Please do a good job of docking with the driver and complete registration form of the delivery personnel.

Receiving member Li Liang: Okay, leader Zhang, I'll reconfirm the related information according to the appointment registration form.

Leader Zhang of Receiving Team: A few days ago, I inspected the warehouse and found that some goods were not stacked up to standard. I have instructed relevant personnel to re-stack them. This receiving operation must be strictly implemented in accordance with the work standards and specifications.

Receiving member Li Liang: I’ve noted it, leader Zhang, we will definitely follow the standard operating procedures and urge the staff to do a good job in receiving goods this time.

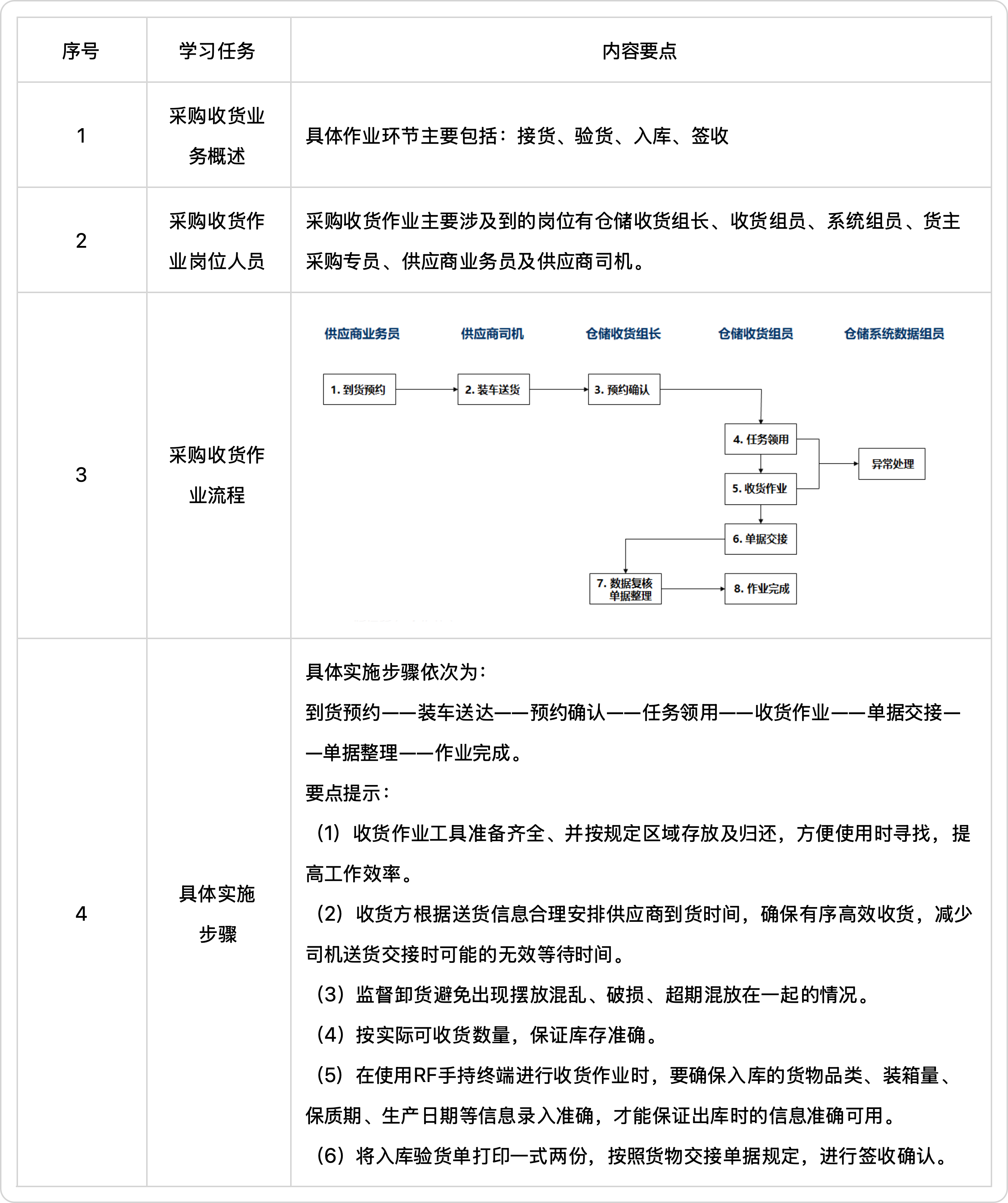

采购收货业务认知 The Cognition of the Purchase and Receipt Operation

采购收货是仓储业务的核心业务之一,到货商品通常为整箱货、数量较大,具体作业环节主要包括:

1.接货:仓库接收运输公司送到的货物,并检查送货单据和实际货物是否一致。

2.验货:仓库工作人员对货物进行检查,核对数量、规格、型号等信息,确保与采购订单或发货单据一致。

3.入库:验货无误后,仓库工作人员将货物放入相应的库位,并记录入库信息,包括入库时间、货物品名、数量、规格等。

4.签收:仓库工作人员对入库的货物进行签收,确认收到货物并完成入库手续。

Procurement and receipt is one of the core businesses of warehousing operation, and the arriving goods are usually FCL goods with large quantities, and the specific operation links mainly include:

1.Receiving: The warehouse receives the goods delivered by the transportation company, and checks whether the delivery documents are consistent with the actual goods.

2.Inspection: The warehouse staff inspects the goods, checks the quantity, specifications, models and other information to ensure that they are consistent with the purchase order or delivery documents.

3.Warehousing: After the inspection is finished, the warehouse staff will put the goods into the corresponding inventory location and record the warehousing information, including the warehousing time, the name of the goods, the quantity, the specifications, etc.

4.Signing: The warehouse staff signs for the warehousing of the goods, confirms the receipt of the goods and completes the warehousing procedures.

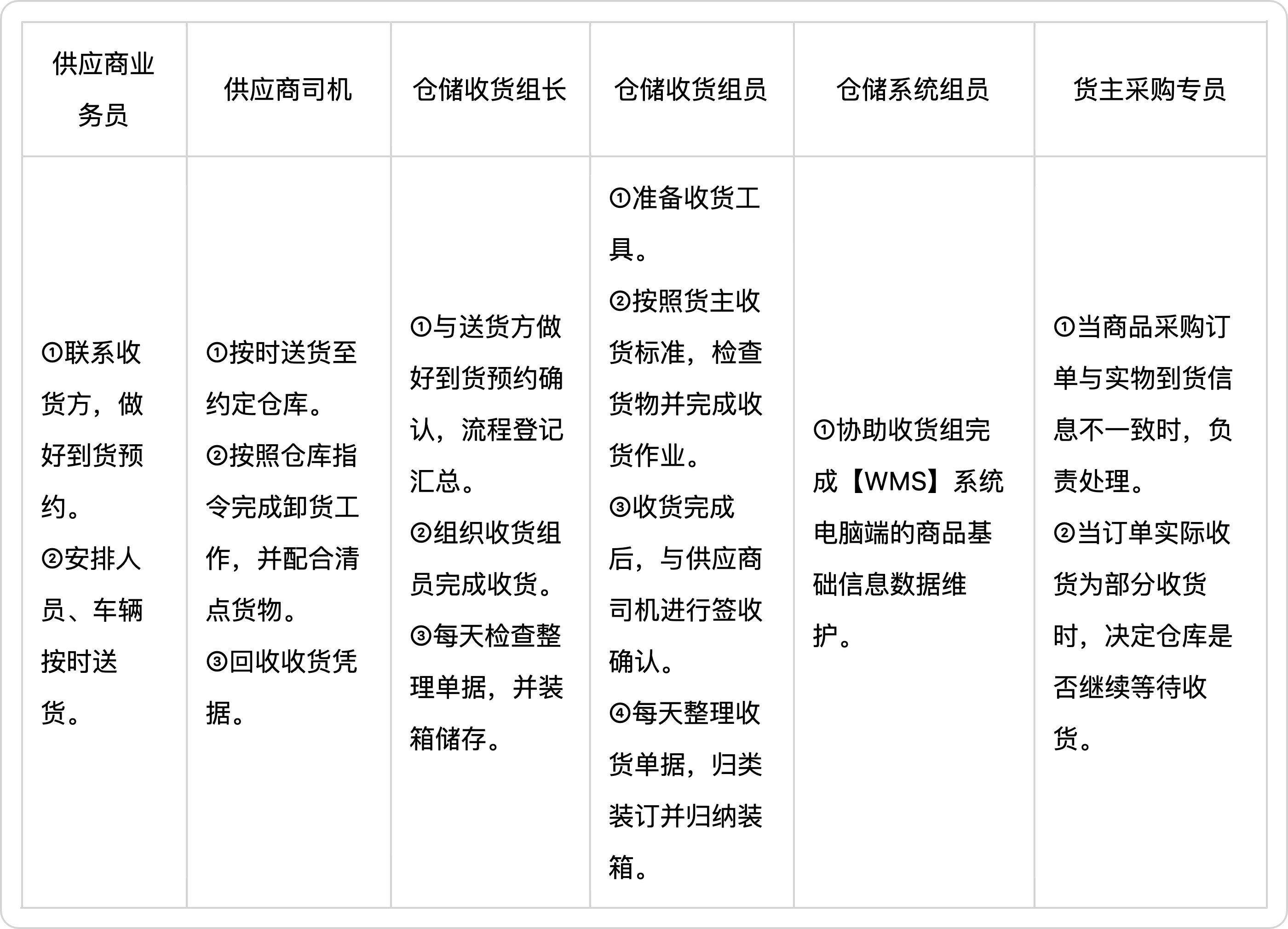

采购收货岗位人员及其职责 Purchasing and Receiving Personnel and Their Responsibilities

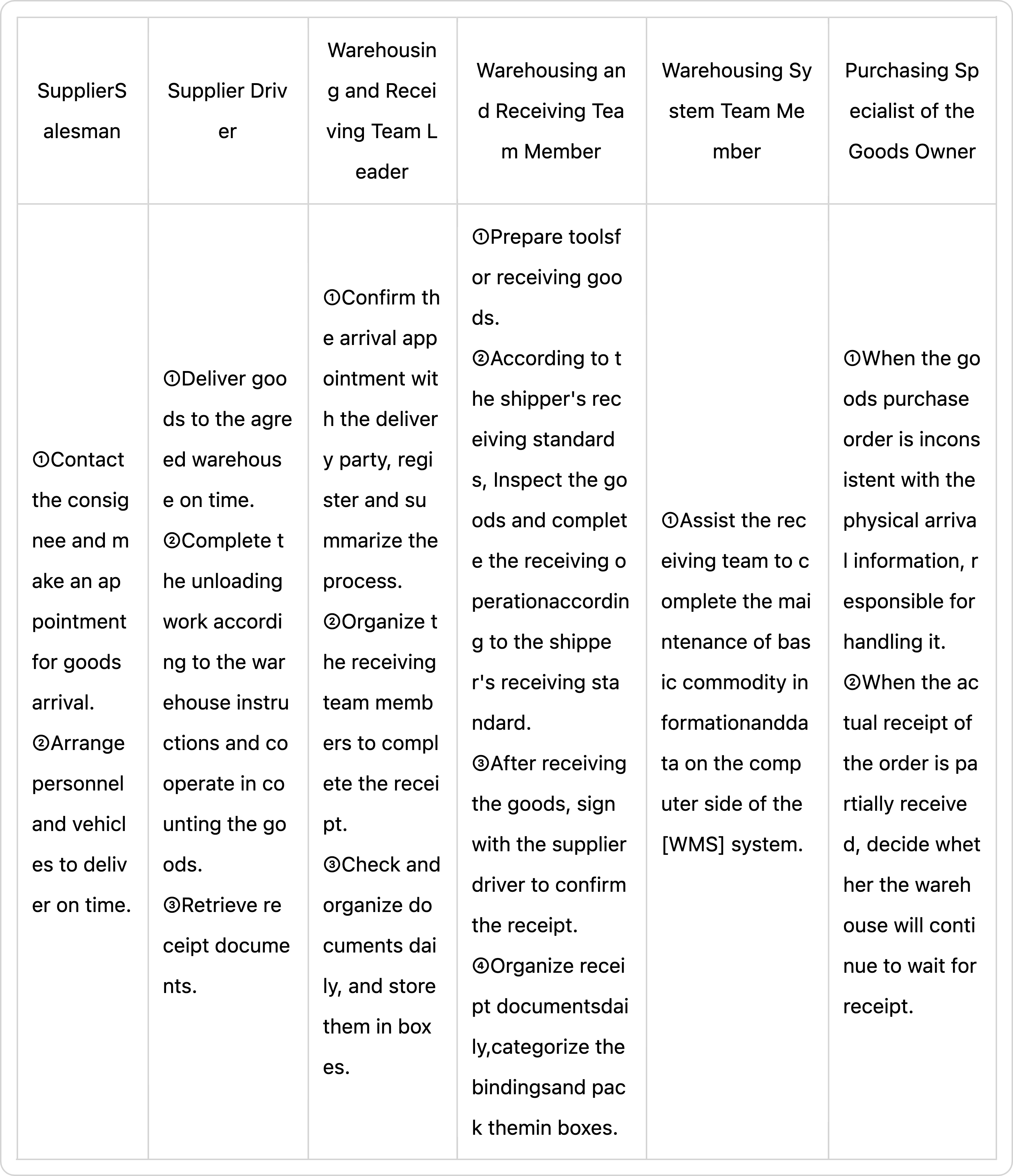

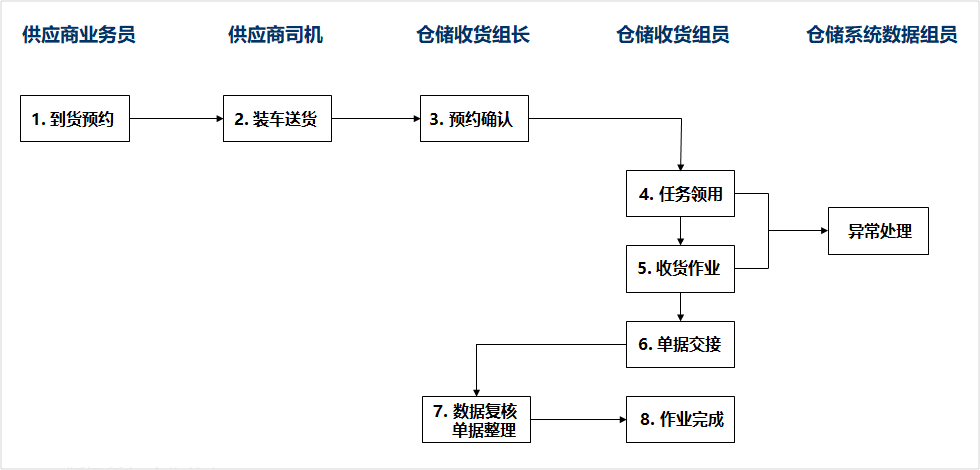

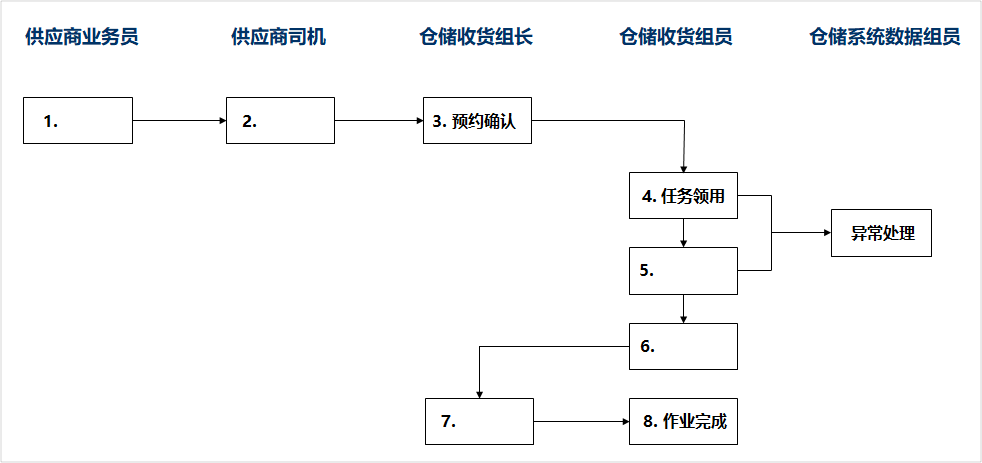

采购收货作业流程 The Process of Purchasing and Receiving Operation

具体实施步骤 Specific Implementation Steps

到货预约

(1)送货方与收货方做到货预约。送货方供应商业务员需要提前一天以上通过电话或者邮件的方式通知收货方,内容包含商品采购订单号、到货时间,车辆及货物信息等,并与收货方确认到货时间和地址。

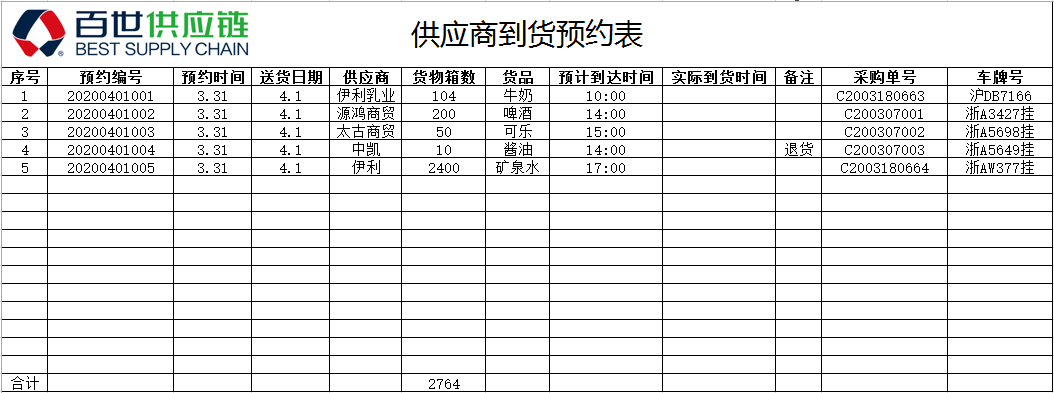

(2)收货方需要填写到货预约登记,收货组长根据预约信息填写“供应商到货预约表”(图1.2.2),统计第二天到货供应商数量。

(3)送货方要及时安排司机送货。

Arrival appointment

(1)The delivery party and the receiving party make an appointment for the arrival of goods. The supplier’s salesperson of delivery party needs to notify the recipient at least one day in advance by phone or email, which contains such as the purchase order number, delivery time, vehicle and goods information, and they should also confirm the delivery time and address with the recipient.

(2)The receiving party need to fill in the arrival appointment registration, and the receiving team leaders fills in the "Supplier Arrival Appointment Form" (Figure 1.2.2) according to the appointment information, and counts the number of arriving suppliers on the next day.

(3)The delivery party should arrange the driver to deliver the goods in time.

装车送货

(1)供应商司机按照约定时间送货至指定仓库。

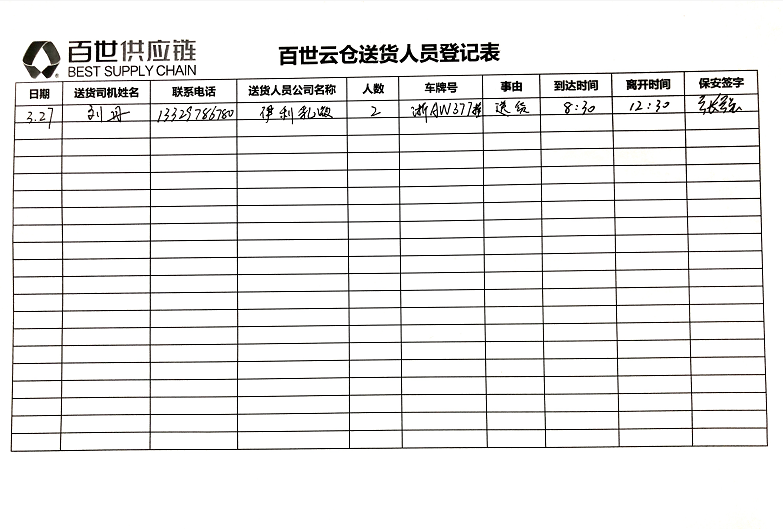

(2)司机找到收货组员后填写“送货人员登记表”(图1.2.3)。

(3)收货组员确认车辆信息与到货预约一致后,安排司机将车辆停靠至指定月台。

(4)司机提供“送货单”和与收货组长打印的“商品采购订单”进行单据对照确认。

(5)确认无误后,领取工具卸货。

(6)收货组员告知货物码放规定和商品收货标准,司机开始卸货,将货物运送至收货组员安排的收货暂存区,并有序摆放,可参考图1.2.4。

Loading and delivery

(1)The supplier's driver delivers the goods to the designated warehouse at the agreed time.

(2)The driver fills in "Delivery Personnel Registration Form" after finding the receiving team member. (Figure 1.2.3).

(3)After confirming the vehicle information is consistent with the arrival appointment, the receiving team members arrange the driver to park the vehicle to the designated platform.

(4)The driver provides the "Delivery Note", it should be compared and confirmed against a document of "Goods Purchase Order" printed by the receiving team leader.

(5) After confirmation, pick up the tools to unload the goods.

(6)The receiving team member informs the goods stacking regulations and receiving standards. The driver begins to unload the goods and transports the goods to the receiving temporary storage area arranged by the receiving team members, and places them in an orderly manner, as shown in Figure 1.2.4.

任务领用

(1)收货组员在RF手持终端上点击进入【WMS】系统,首次登陆时,需要输入操作者本人的用户代码和用户口令,登录系统(图1.2.5)。

(2)在首页点击进入【LPN收货】界面(图1.2.6)。

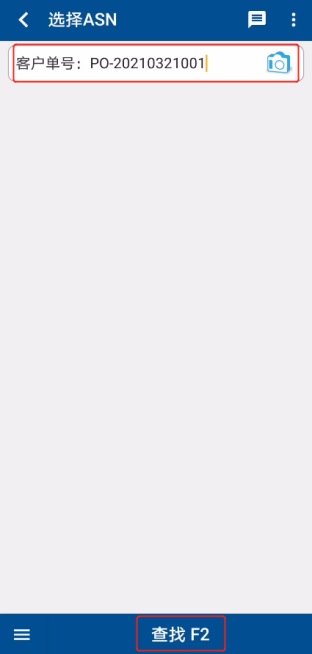

(3)在【客户单号】处,扫描“商品采购订单”上的订单条码(图1.2.7)。

Task requisition

(1)The receiving team members click on the RF handheld terminal to enter into【WMS】system. When logging in for the first time, they need to enter the operator's user code and password to login to the system (Figure 1.2.5).

(2)Click on the home page to enter the 【LPN receiving】 interface (Figure 1.2.6).

(3) Scan the order barcode on the "Goods Purchase Order" at the place of【Customer Order Number】(Figure 1.2.7).

收货作业

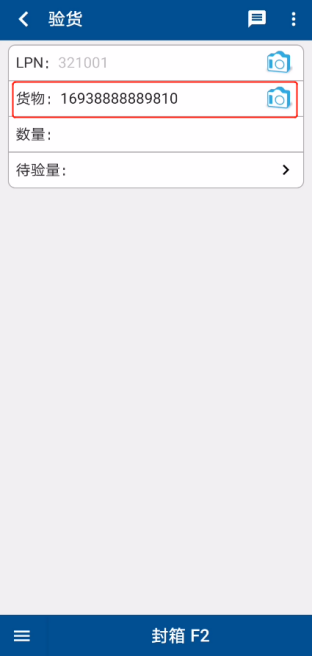

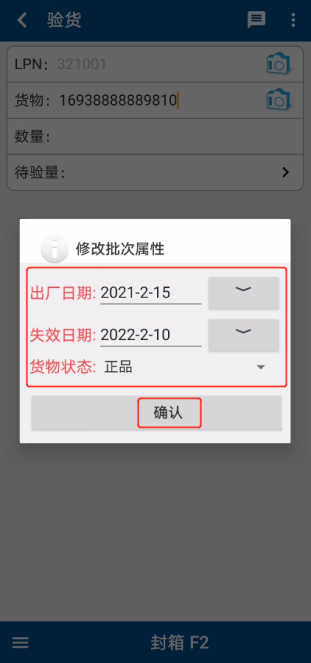

(1)进入【验货】界面。确保入库的货物品类、装箱量、保质期、生产日期等信息录入准确(图1.2.8——图1.2.11)。

Receiving operation

(1) Enter the 【Inspection】interface. Ensure that the inbound goods category, packing quantity, shelf life, production date and other information are entered accurately (Figure 1.2.8 -- Figure 1.2.11).

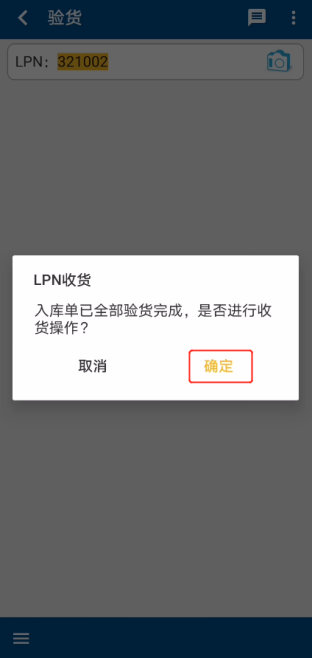

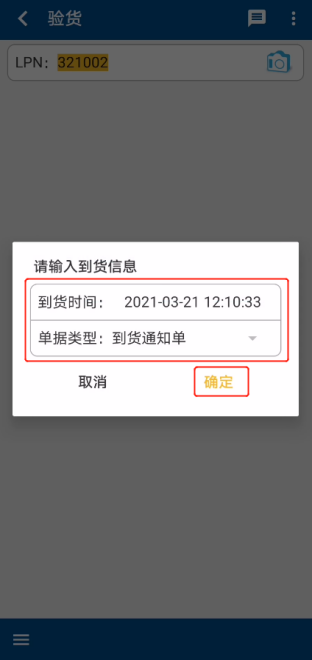

(2)订单完成验货后,系统提示【验货完成】,点击【确定】,系统提示【收货成功】,收货作业结束(图1.2.12——图1.2.13)。

(2) After completing the inspection of the order, the system prompts 【Inspection Completed】, click 【OK】, the system prompts 【Receipt Successful】, and the receiving operation completed. (Figure 1.2.12 – Figure 1.2.13).

单据交接

(1)收货完成后,在系统打印交接凭据。

(2)双方进行验货签收。

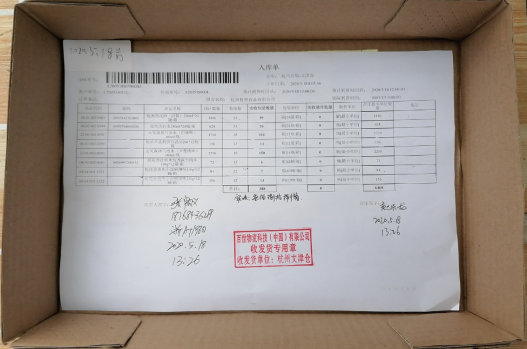

将入库验货单打印一式两份,按照货物交接单据规定,进行签收确认。仓库人员与供应商司机各留存一份。

Documents handover

(1)When receipt is complete, print the handover voucher in the system.

(2) Both parties carry out an inspection and sign for the goods.

Print the inbound inspection form in duplicate and sign for confirmation in accordance with the provisions of the goods handover documents. Warehouse personnel and supplier drivers each keep one copy.

单据整理

(1)收货组员每天整理收货单据(包含供应商送货单、商品采购订单、入库验货单),按日期归类装订好,并在固定位置(左上角)粘贴日期标签,放置在指定归纳盒中(图1.2.14——图1.2.15)。

Document collation

(2)The receiving team members organize the receiving documents daily (including supplier delivery notes, goods purchase orders, and inbound inspection forms), classify and bind them by date, and paste date labels in a fixed position (upper left corner), placing them in the designated induction box (Figure 1.2.14 - Figure 1.2.15).

专业核心词汇 Vocabulary

采购收货作业 purchasing and receiving operation

到货预约 arrival appointment

装车送货 loading and delivery

商品采购订单 goods purchase order

送货单 delivery note

客户单号 customer order number

货物条码 goods barcode

装箱量 packing quantity

验货 inspection

入库验货单 inbound inspection form

学习拓展 Further Reading

百世物流规范标准——货物码放规定

一、整箱整托

1.货物码放应整齐,不能歪斜、倒塌。

2.每层码放的数量及相同货品每托数量应码放一致。

3.货物码放不能超出托盘,整体高度不能超过1.6米。

4.货品外箱条码应朝外摆放。

二、整箱混托

1.同一块托盘码放多种货品时,要区分摆放。

2.每个托盘不允许码放超过4种货品。

3.同一托盘上存放的同一货品效期不能超过3天且不能跨月。

4.易碎品、外箱光滑、高价值货物必须使用缠绕膜,缠绕3层确保封紧。

5.外观相似的不同货品禁止码放在同一托盘上。

具体可参考图1.2.16。

BEST Logistics Standard - Regulations on Goods Stacking

Ⅰ FCL Pallet

1.The goods should be neatly stacked and not tilted or collapsed.

2.The quantity of stacks on each layer and the quantity of each pallet of the same goods should be consistent.

3.The goods cannot be stacked beyond the pallet, and the overall height cannot exceed 1.6 meters.

4.The barcode on the outer box of the goods should be placed facing outward.

Ⅱ FCL Mixed Pallet

1.When stacking multiple goods on the same pallet, they should be placed separately.

2.No more than 4 kinds of goods are allowed to be stacked on each pallet.

3.The The expiration date of the same goods stored on the same pallet cannot exceed 3 days and cannot span months.

4.The fragile goods, smooth outer boxes, and high-value goods must be wrapped with 3 layers of winding film to ensure tight sealing.

5.Different goods with similar appearances are prohibited from being stacked on the same pallet.

Please refer to Figure 1.2.16 for details.

知识巩固 Consolidation

排序题

以下词条为采购收货作业具体步骤,如扫描ASN单号为第一步,则用数字标明①,后续步骤请按照作业顺序依次进行编号。

扫描ASN单号(①)

修改批次属性( )

输入货物数量( )

录入到货时间( )

扫描货物条码( )

验货完成提示( )

答案:① ③ ④ ⑥ ② ⑤选择题

请根据所学知识,将采购收货作业流程填写完整。

A.工具准备

B.到货预约

C.装车送货

D.收货作业

E.单据交接

F.数据复核单据整理

答案:1.B 2.C 5.D 6.E 7.F判断题

根据所学知识,参考企业货物码放规范标准,你认为操作正确的画√,操作不当的画×。

答案:× × × √技能训练

训练任务:收货(采购收货)作业

【训练目标】

1.熟练掌握收货(采购收货)作业流程,并能够准确熟练完成WMS系统操作。

2.通过实训,掌握收货验收作业流程,包括核对单据内容检查货物外观与数量以及确认验收工作,并学会对验收过程中的异常货品进行处理。要求学生在验收过程中做到准确无误,严肃认真。

【训练内容】

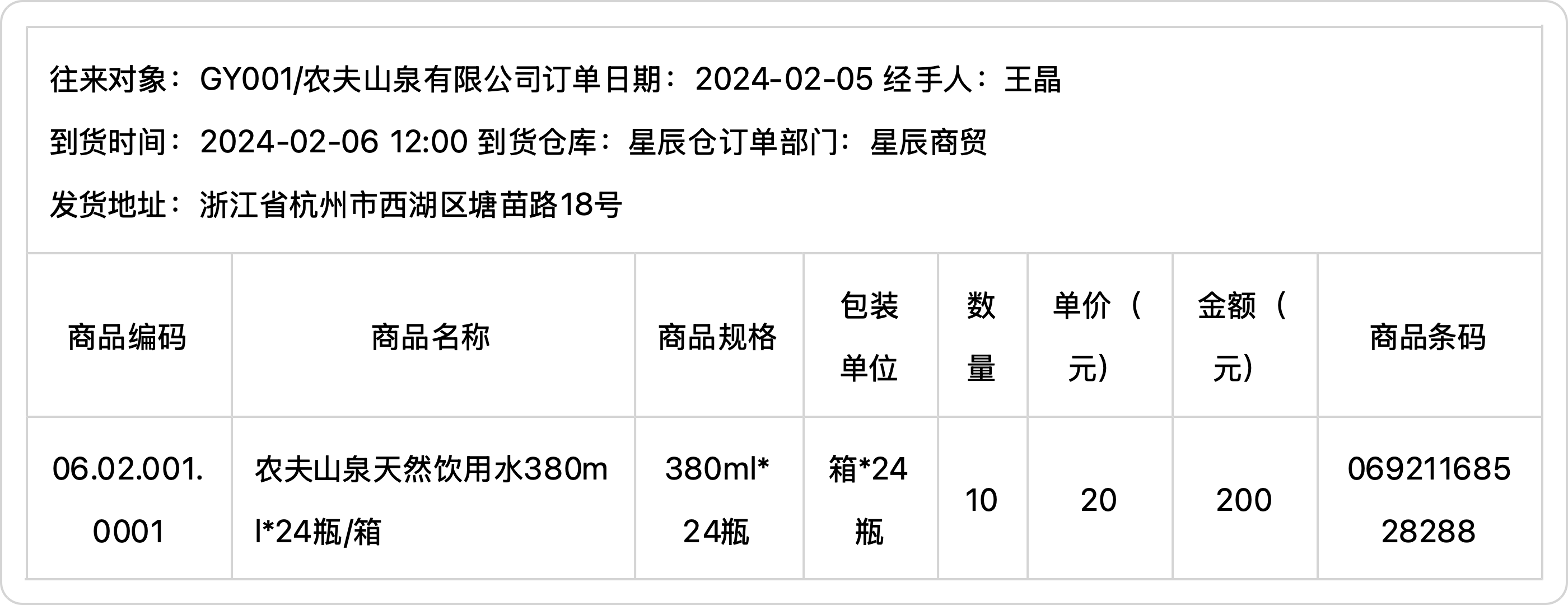

1.星辰商贸在【ERP】创建了一份采购订单,具体信息如下:

2.系统组员登录【WMS】系统,收到一份预计到货通知,具体信息如下表所示:

请以小组为单位,分配岗位角色,完成收货(采购收货)作业。

【训练步骤】

1.送货方与收货方做到货预约。

2.收货组长根据预约信息填写供应商到货预约表。

3.收货组员确认车辆信息与到货预约一致后,安排司机将车辆停靠至指定月台。

4.收货组员开始系统收货,进入【LPN收货】界面。

5.收货组员进行货物验收,进入【验货】界面。

6.收货完成后,在系统打印交接凭据,双方进行验货签收。

7.收货组员每天整理收货单据,收货组长每天检查整理好的单据,按日期将纸质文件汇总打包,装箱储存。

【考核评价】

微课

自动化技术应用

工作视频

采购收货作业-1工具准备

采购收货作业-2到货预约

采购收货作业-3货物送达

采购收货作业-4系统操作

采购收货作业-5异常处理

课件

任务小结

本节课学习任务要点梳理如表1.2.5所示: